1/4 Luan Plywood - Polyester Faced Overlay Plywood

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 21 m³

- Supply Capability:

- 100000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications:

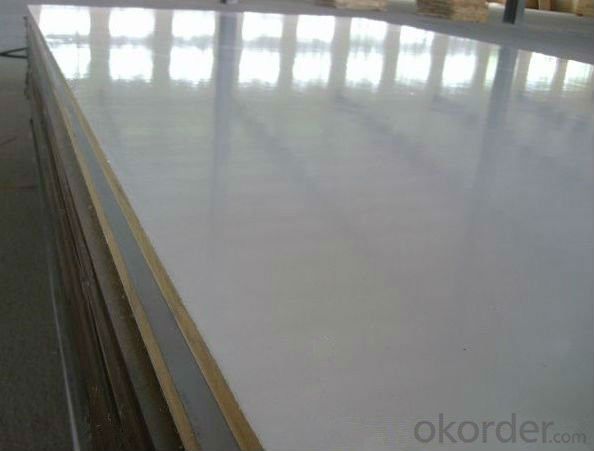

Polyester Plywood

Good Quality & Price

1)Color: solid color, wood grain or marble grain

2)Core: poplar, hardwood, combi

Product Description:

Product Name | COLORFUL POLYESTER PLYWOOD MELAMINE FACED PLYWOOD | |||||

Size | 1220x2440mm, 915x2135mm or as clients requirement | |||||

Thickness | 3~25mm | |||||

Thickness Tolerance | +/-0.2mm (thickness<6mm), +/-0.3~0.5mm (thickness≥6mm) | |||||

Face/Back | Wood veneer laminated first, then one side or both side melamine laminated | |||||

Surface Treatment | Matt, textured or glossy | |||||

HPL Color | Gray white (There also have other more than 300 kinds color available: solid color (such as black, red, blue, orange, green, ect.) & wood grain (such as beech, cherry, walnut, teak, oak, maple, sapele, ect.) & marble grain.) | |||||

HPL Thickness | 0.5~1mm | |||||

Core | Poplar, hardwood, eucalypt, okoume, birch, pine, combi, ect. | |||||

Joint Way of The Core | Overlap joint, end joint, scarf joint or finger joint | |||||

Glue | E0, E1, E2, MR, Melamine or WBP | |||||

Grade | A grade or as clients requirement | |||||

Density | 500~680kg/m3 | |||||

Technical Parameters | Moisture Content | 10%~15% | ||||

Water Absorption | ≤10% | |||||

Modulus of Elasticity | ≥5000Mpa | |||||

Static Bending Strength | ≥30Mpa | |||||

Surface Bonding Strength | ≥1.60Mpa | |||||

Internal Bonding Strength | ≥0.90Mpa | |||||

Screw Holding Ability | Face | ≥1900N | ||||

Edge | ≥1200N | |||||

Usage & Performance | HPL faced plywood is widely used for furniture, cabinet and interior decoration. With good properties, such as, acid & alkali resistant, heat resistant, easy fabricability, anti-static, easy cleaning, long-lasting and no seasonal effect. | |||||

Packing | Standard Export Pallet Packing | Inner Packing | Pallet is wrapped with a 0.20mm plastic bag | |||

Outer Packing | Pallet is covered with plywood or carton and then PVC/steel tapes for strength | |||||

Loading Quantity | 20’GP | 8pallets/22cbm | ||||

40’GP | 16pallets/42cbm | |||||

40’HQ | 18pallets/53cbm | |||||

MOQ | 1x20’ FCL | |||||

Supply Ability | 5000cbm/month | |||||

Payment Terms | T/T or L/C at sight | |||||

Delivery Time | Within 15 days after receiving deposit or original L/C at sight | |||||

Delivery | loading in 7-10 days or shorter by clients special request.x | |||||

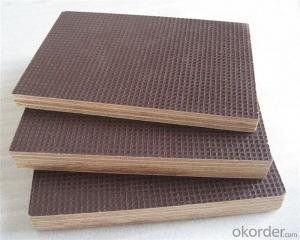

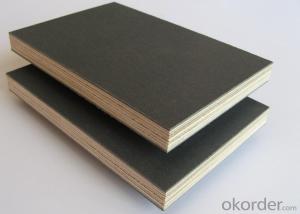

FEATURES:

High bending strength

2.Strong nail holding

3.Moisture-proof and easy work

4.Tight construction and high strength

5.No ratten or decay

6.Low formaldehyde emission

7.The productions are suitable for the construction of viaduct and tall frame building

8.If put in boiling water for 48 hours,it still glue sticking and still formed

9.If used abide by illustration strictly,it can be reuse more than 50 times

10.Solve the problem of leaking and rough surface during construction process

FAQ:

1.Free samples are avaliable

2.Delivery time:20days after getting deposit

3.Payment terms:T/T or L/C at sight

- Q: Plywood in the material defects?

- Abnormal structure Any defects caused by abnormal wood construction, such as wrinkles. Wavy pattern. Staggered pattern, spiral pattern and so on.

- Q: triple? Nail gun Self-tapping screws? Cork Or other?

- A group of veneers are usually in the direction of adjacent layers of wood grain perpendicular to the formation of each other

- Q: Class I resistant weather plywood Class II water resistant plywood

- Medium density fiberboard: density fiberboard is a kind of man-made sheet, it is the plant fiber as raw material, the chipping, fiber separation

- Q: Furniture solid wood and plywood which is better? Such as bed `wardrobe` TV cabinet `table

- the difference between the process: multi-layer solid wood flooring will be a layer of each layer of scientific criss-cross, to eliminate internal stress, at present, its layers have grown from 7 to 9 layers, 11 layers

- Q: What is the density of plywood?

- Plywood can improve timber utilization and is a major way to save wood

- Q: Distinguish between multilayer boards and plywood

- With the veneer after the wood by the direction of the criss-cross the composition of the slab, heated or not heated under the conditions of suppression.

- Q: Why is the plywood commonly used in the singular layer

- if put a piece into a striped. (Then this time there will be positive is the pattern of wood

- Q: The basic principle of plywood

- The principle of symmetry is to require plywood symmetry on both sides of the plate, regardless of the nature of the wood, the thickness of the plywood, the layer, the fiber direction, the water content, etc

- Q: What are the types of veneer veneer veneer?

- Common is a single-sided veneer veneer plywood. Decorative veneer commonly used species of birch, ash, oak, water green Kong, elm, maple wood, walnut, etc.

Send your message to us

1/4 Luan Plywood - Polyester Faced Overlay Plywood

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 21 m³

- Supply Capability:

- 100000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords