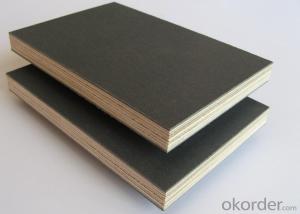

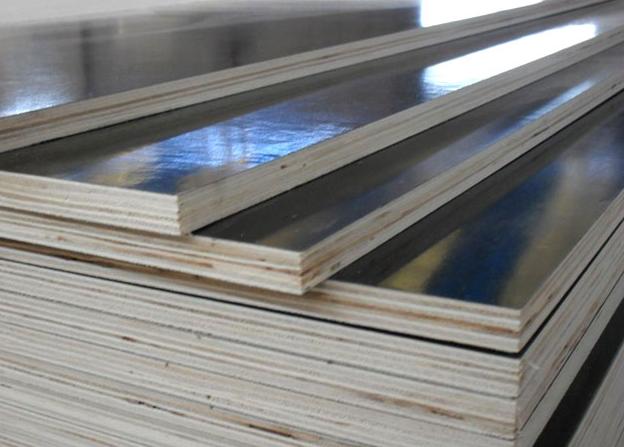

1/2 4x8 Brown Film Faced Plywood / Black Film Faced Plywood / Plywood

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specification

Type:

Film Faced Plywood

Application:

For Construction

Quick Details

| Type: | Place of Origin: | ||||

| Model Number: | Usage: | Grade: | |||

| Main Material: | Formaldehyde Emission Standards: | Plywood Type: | |||

| Veneer Board Surface Finishing: | Veneer Board Surface Material: | core: | |||

| glue: | moisture: | thickness tolerance: | |||

| film: |

Packaging & Delivery

| Packaging Detail: | Packaging Detail: wood pallet packing, loose packing or as customer's requirement Delivery Detail: within 2 weeks |

| Delivery Detail: | 15 days after deposit or L/C at sight |

Specifications

Brown/BlackFilm Face Plywood

1)size:1220*2440mm,1250*2500mm

2)core:poplar,Combi,hardwood

3)glue:WBP,MR,MLM

4)thickness:6-25m

1. Brown/Black Film Face Plywood , Marine Plywood for construction

| Size: | 915mmx1830mm,610x2440mm,1220x2440mm,1250x2500mm,1500x3000mm |

| Film: | chinese brown(240g/m2), Dynea brown(120g/m2) , black film(240g/m2) |

| Core: | poplar , birch ,hardwood core, poplar and hardwood mix core |

| Thickness: | 6mm,9mm,12mm,15mm,18mm,21mm,25mm |

| Glue: | Mr,wbp ,waterproof melamine glue |

| Density: | 530-600kg/cbm |

| Moisture: | less than 12% |

| Thickenss tolerance : | +/-0.5mm |

| Modulus of rupture: | ≥30Mpa |

| Modulus of Elasticity | ≥6000Mpa |

- Q: What does plywood mean and its synthesis?

- Plywood is one of the common materials for furniture, one of the three panels of man-made board, but also for aircraft, ships, trains, cars, construction and packaging materials

- Q: Now what is the market for plywood development?

- has also been greatly improved in the international market more and more competitive. China is not only a large veneer export, or the world's largest plywood producer.

- Q: According to the different composition of the glue, for the construction of plywood with the following types of glue

- According to the environmental protection level, the glue used for plywood can be divided into E0 grade, E1 glue, E2 glue (and even E2 level are not reach the unqualified glue)

- Q: What is the use of plywood for construction?

- The number of veneer layers is odd, usually three to thirteen layers, common plywood, pallets, pallets

- Q: Ordinary plywood is divided into four categories

- Wood fiber or other plant fiber as raw material to be pressed into a density of 0.50 ~ 0.88g / cm3 plate

- Q: Classification of plywood for construction

- if you want to make general indoor wood products, you can use E1 (or even E0) urea formaldehyde

- Q: Class III resistant tide plywood class IV tonic resistant plywood

- It is usually made of odd-numbered veneers and The fibers of the adjacent veneers are perpendicularly bonded to each other

- Q: What is medium density fiberboard

- Plywood commonly known as three plywood, five plywood, nine PCT board, twelve PCT board and so on

- Q: What kind of glue is today's plywood?

- if you want to make outdoor use of wood products, you can use E1 grade (or even E0 level) phenolic glue.

Send your message to us

1/2 4x8 Brown Film Faced Plywood / Black Film Faced Plywood / Plywood

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords