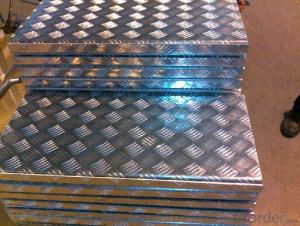

Tread Plate Aluminum

Tread Plate Aluminum Related Searches

Led Light Bulbs For Ceiling Fixtures Led Lamps For Ceiling 42 In Ceiling Fan With Light Aluminum Coil Stock For Gutters Aluminum Foil For The Grill Hole Saw For Aluminum Plate Aluminum Tread Plate For Trailer Bow Plate For Aluminum Boat Aluminum Foil For Grow Room Aluminum Foil For Joint PainHot Searches

Stock Price For Aluminum Aluminum Coil Stock For Sale Aluminum Gutter Coil For Sale Used Aluminum Scaffolding For Sale 1/4 Aluminum Plate For Sale Aluminum Bar Stock For Sale Aluminum Round Stock For Sale Aluminum Diamond Plate For Sale Aluminum Scaffolding For Sale Craigslist 6061 Aluminum Plate For Sale Aluminum Dock Plate For Sale 7075 Aluminum Plate For Sale Aluminum Tread Plate For Sale Aluminum Checker Plate For Sale Aluminum Plate For Sale Near Me Plate Aluminum For Sale Aluminum Plate For Sale Aluminum Square Stock For Sale Aluminum Flat Stock For Sale Billet Aluminum Stock For SaleTread Plate Aluminum Supplier & Manufacturer from China

Okorder.com is a professional Tread Plate Aluminum supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Tread Plate Aluminum firm in China.Hot Products

FAQ

- Yes, aluminum sheets are suitable for boat building. Aluminum is a popular material choice for boat construction due to its numerous advantageous properties. Firstly, aluminum is lightweight, which makes it easier to handle and transport during the boat building process. This lightweight characteristic also contributes to better fuel efficiency and improved overall performance of the boat. Additionally, aluminum is highly resistant to corrosion, especially in saltwater environments, making it an ideal choice for boat building. This resistance to corrosion ensures that the boat remains durable and maintains its structural integrity for a longer period of time, even when exposed to harsh weather conditions. Furthermore, aluminum sheets offer excellent strength-to-weight ratio, providing a sturdy and reliable structure for the boat. This strength allows the boat to withstand the forces encountered while sailing, ensuring a safe and enjoyable experience for the occupants. Moreover, aluminum is a versatile material that can be easily molded and shaped into various boat designs. This flexibility allows for customization and the creation of unique boat designs that meet specific requirements and preferences. Lastly, aluminum is a sustainable and environmentally friendly material. It is fully recyclable, reducing the environmental impact of boat building and promoting a greener approach to marine construction. In conclusion, aluminum sheets are indeed suitable for boat building due to their lightweight nature, corrosion resistance, strength, versatility, and eco-friendliness.

- AND WAT R THE THECNOLOGICAL ANDCOSTS AND BENEFITESOF USING ALUMINUM? what health -related and environment-related issues gave surface as aresult of its widespread use in society?

- airplanes are made from aluminum. certain beverages are also. aluminum is cheaper and lighter. the biggest problem is the amount of electricity that it takes to make aluminum

- The thickness of an aluminum sheet can be measured using various methods. One common technique is to use a micrometer or caliper, which are precision measuring tools. The micrometer is placed on one end of the sheet and slowly closed until it touches the other end, providing an accurate measurement of the thickness. This method is effective for measuring thin aluminum sheets. For thicker sheets, a thickness gauge can be used. It consists of a small handheld device with a probe that is pressed against the sheet's surface. The gauge then displays the thickness reading on a screen. This method is especially useful for measuring thicker sheets where a micrometer or caliper may not be suitable. Another way to measure the thickness of an aluminum sheet is by using an ultrasonic thickness gauge. This tool emits ultrasonic waves from a transducer, which are then reflected back from the sheet's surface. By calculating the time taken for the waves to travel and return, the gauge can determine the thickness of the sheet with high accuracy. This method is particularly effective for measuring the thickness of large or irregularly shaped aluminum sheets. In summary, the thickness of an aluminum sheet can be measured using various tools such as a micrometer, caliper, thickness gauge, or ultrasonic thickness gauge, depending on the thickness and size of the sheet.

- Yes, aluminum sheets are suitable for automotive heat shields. They have excellent thermal conductivity and high melting point, making them effective in dissipating heat and protecting sensitive components from excessive temperature. Additionally, aluminum is lightweight and corrosion-resistant, which are desirable qualities for automotive applications.

- Yes, aluminum sheets can be suitable for manufacturing electronics components. Aluminum is preferred for certain applications due to its lightweight, good thermal conductivity, and electrical conductivity properties. However, the suitability of aluminum sheets depends on the specific requirements and design of the electronics components being manufactured.

- Yes, aluminum sheets can be anodized to improve their hardness. Anodizing is an electrochemical process that forms a protective oxide layer on the surface of aluminum. This oxide layer not only enhances the sheet's corrosion resistance but also increases its hardness, making it more resistant to wear and abrasion. By controlling the anodizing conditions, such as the type of electrolyte, voltage, and duration, the thickness of the oxide layer and consequently, the hardness of the aluminum sheet can be precisely adjusted. Anodized aluminum sheets find applications in various industries, including automotive, aerospace, construction, and electronics, where a combination of improved hardness and corrosion resistance is required.

- Yes, aluminum sheets are suitable for outdoor applications. Aluminum is highly resistant to corrosion and weathering, making it an ideal choice for outdoor use. Additionally, aluminum sheets are lightweight, durable, and have excellent thermal and electrical conductivity, further enhancing their suitability for various outdoor applications.

- Yes, aluminum sheets are suitable for furniture manufacturing. Aluminum is a lightweight and versatile material that offers numerous advantages for furniture production. It is corrosion-resistant, making it ideal for both indoor and outdoor furniture. Additionally, aluminum has a high strength-to-weight ratio, allowing for the creation of sturdy and durable furniture pieces. It is also easy to work with, as it can be cut, bent, and welded into various shapes and designs. Moreover, aluminum can be finished with different coatings or paints to enhance its appearance and protect it from wear and tear. Overall, aluminum sheets are a viable option for furniture manufacturing due to their strength, versatility, and aesthetic appeal.