Stainless Steel Smoker Pipe

Stainless Steel Smoker Pipe Related Searches

Best Paint For Stainless Steel Blanket Insulation For Steel Buildings Primer For Galvanized Steel Foam Filter For Stainless Steel H S Code For Stainless Steel Surface Grinding Wheels For Stainless Steel Surface Grinding Wheels For Hardened Steel Hole Saw For Stainless Steel Paint For Stainless Steel Stainless Steel For BbqHot Searches

Steel Mesh Panels For Sale Price For Stainless Steel Scrap Scrap Price For Stainless Steel Price For Stainless Steel Stainless Steel Tank For Sale Stainless Steel Sheets For Sale Cheap High Tea Sets For Sale Stainless Steel Tanks For Sale Stainless Steel For Sale High Density Fiberboard For Sale Solar Hot Water Collectors For Sale Scaffolding For Sale In Uae Scaffolding For Sale In Ireland Scaffolding For Sale In Houston Type Of Inverter For Solar Price Of Shipping Containers For Sale Types Of Inverter For Solar Stock Price For Aluminum Used Solar Inverter For Sale Steel Mesh Panels For SaleStainless Steel Smoker Pipe Supplier & Manufacturer from China

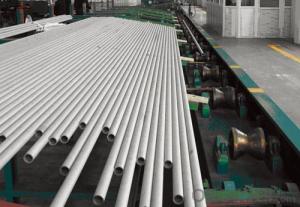

Okorder.com is a professional Stainless Steel Smoker Pipe supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Stainless Steel Smoker Pipe firm in China.Hot Products

FAQ

- Stainless steel pipes are tested for quality through various methods including visual inspection, dimensional checks, chemical analysis, and mechanical testing. These tests ensure that the pipes meet the required standards and specifications, ensuring their durability, corrosion resistance, and overall quality.

- Indeed, cryogenic storage tanks can indeed utilize stainless steel pipes. Renowned for its exceptional resistance to corrosion, durability, and strength, stainless steel proves itself as an appropriate choice for the containment of exceedingly cold liquids or gases. Specifically designed for materials preservation at extremely low temperatures, typically below -150 degrees Celsius, cryogenic storage tanks necessitate materials that will not become brittle or compromise their mechanical properties. Stainless steel pipes effectively withstand these frigid temperatures without faltering. Furthermore, stainless steel's low thermal conductivity assists in minimizing heat transfer and maintaining the desired temperature within the storage tank. Consequently, stainless steel pipes are widely employed in cryogenic storage tanks to guarantee the secure and efficient storage of cryogenic substances.

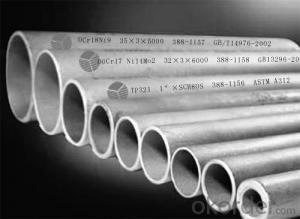

- 304 stainless steel, welded to seamless difference in what place?

- The seamless tube is made by pressing a hole in a stainless steel billet at a temperature of 2200 degrees F. At this high temperature, the tool steel is made soft and spirally shaped from the hole by stamping and drawing. Thus, the wall thickness of the pipeline is uneven and the eccentricity is high. Thus ASTM allows seamless pipe wall thickness ratio of the wall thickness difference of seamed tube. Through the seamed tube cold rolling plate precision (per roll width is 4-5 feet) made. These cold rolled plates usually have a maximum wall thickness of 0.002 inches. The steel plate is cut into a width of PI D, in which D is the outer diameter of the pipe. Tube wall thickness tolerance is very small, and the entire circumference of the wall thickness is very uniform.

- Passivation is a process used to enhance the corrosion resistance of stainless steel pipes. Stainless steel is known for its excellent resistance to corrosion, but it can still be susceptible to localized corrosion under certain conditions. Passivation helps to prevent this by removing any free iron or iron oxide particles from the surface of the stainless steel pipes. During the passivation process, the stainless steel pipes are cleaned thoroughly to remove any contaminants or impurities that may be present on the surface. This can be done through various methods such as chemical cleaning or mechanical cleaning techniques. Once the pipes are cleaned, they are treated with a passivating agent, typically a nitric acid solution. The passivating agent works by dissolving any iron or iron oxide particles on the surface of the stainless steel pipes. This helps to create a protective oxide layer on the surface, which acts as a barrier against corrosion. This oxide layer is typically very thin, transparent, and self-repairing, providing long-term protection against corrosion. Passivation is a crucial step in the manufacturing process of stainless steel pipes, as it ensures the pipes have the highest level of corrosion resistance. It is particularly important in industries where the pipes are exposed to harsh environments or corrosive substances, such as chemical processing plants, oil and gas refineries, or marine applications. Overall, passivation plays a vital role in maintaining the longevity and performance of stainless steel pipes by enhancing their corrosion resistance and protecting them from localized corrosion.

- To clean stainless steel pipes, you can start by using a mixture of warm water and mild soap to scrub the surface of the pipes with a soft cloth or sponge. Make sure to rinse well and dry thoroughly to prevent water spots or streaks. For tougher stains or buildup, you can use a stainless steel cleaner or polish specifically designed for this purpose. Always remember to follow the manufacturer's instructions and test any cleaner on a small, inconspicuous area before applying it to the entire pipe.

- Indeed, dairy processing equipment can utilize stainless steel pipes. Stainless steel is widely favored in the food and beverage sector owing to its remarkable resistance to corrosion, hygienic qualities, and long-lasting nature. Its exceptional ability to ward off rust, stains, and contamination renders it highly suitable for employment in dairy processing equipment, where cleanliness and food safety are of utmost importance. Furthermore, stainless steel pipes possess the capability to endure elevated temperatures and pressures, which are frequently necessary in dairy processing operations. All in all, stainless steel pipes prove to be a dependable and appropriate material for incorporation in dairy processing equipment.

- In general, stainless steel pipes exhibit resistance to stress corrosion cracking. Stainless steel is a material known for its ability to resist corrosion and degradation, thanks to its high levels of chromium and nickel. The occurrence of stress corrosion cracking is typically triggered by a combination of tensile stress, a corrosive environment, and a susceptible material. Nevertheless, stainless steel demonstrates excellent resistance against stress corrosion cracking due to its composition and inherent properties. It can endure high levels of stress without experiencing significant degradation or cracking, making it a suitable choice for applications that necessitate durability and corrosion resistance.

- Stainless steel pipes are indeed a great fit for sanitary purposes. The remarkable corrosion resistance, durability, and hygienic qualities of stainless steel make it the perfect option for settings that call for cleanliness and sanitation, like food processing plants, pharmaceutical facilities, and hospitals. It's worth mentioning that stainless steel pipes are non-porous, meaning they don't absorb or retain bacteria, contaminants, or odors. Moreover, they are effortless to clean and maintain, ensuring the utmost level of hygiene. Furthermore, stainless steel pipes can endure high temperatures and pressures, making them well-suited for a vast array of sanitary applications.