Refinishing Particle Board Cabinets

Refinishing Particle Board Cabinets Related Searches

Micro Inverter For Solar Panel Fiber Sheet For Roof Wall Lights For Bedrooms Geogrid For Retaining Wall Solar Panel With Ac Inverter Solar Panel Kit With Inverter Waterproofing Additive For Cement Render Wall Spotlight With Plug Galvanized Steel Wall Panels Inverter Used In Solar PanelHot Searches

Steel Mesh Panels For Sale Price For Stainless Steel Scrap Scrap Price For Stainless Steel Stainless Steel Tank For Sale Cheap High Tea Sets For Sale Stainless Steel Tanks For Sale High Density Fiberboard For Sale Solar Hot Water Collectors For Sale Scaffolding For Sale In Uae Scaffolding For Sale In Ireland Scaffolding For Sale In Houston Type Of Inverter For Solar Price Of Shipping Containers For Sale Types Of Inverter For Solar Stock Price For Aluminum Used Solar Inverter For Sale Portable Led Signs For Sale Stone Hot Water Bottles For Sale Aluminum Coil Stock For Sale Used Foam Board Insulation For SaleRefinishing Particle Board Cabinets Supplier & Manufacturer from China

Okorder.com is a professional Refinishing Particle Board Cabinets supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Refinishing Particle Board Cabinets firm in China.Hot Products

FAQ

- Market foreground and Industry development

- Particleboard due to poor quality and some other reasons, the market abandoned, many particleboard enterprises learn from the introduction of foreign advanced production lines and improve the level of technology,

- Particleboard production process requires proper hot pressing pressure

- and then sawing sanding, inspection packaging. But after the pressure can not heat stacked, otherwise it will increase the sheet brittle.

- What factors China's Particleboard industry development obstacles to

- the bark and MDF to produce dust and so on are used as raw materials for particleboard, China's production of particleboard generally poor quality, but also the prevalence of formaldehyde seriously exceeded the problem.

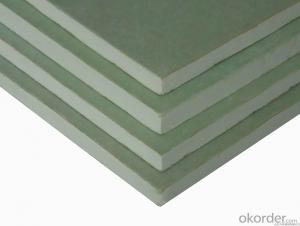

- What are the disadvantages of particleboard?

- in the cutting board is likely to cause the phenomenon of violence teeth, so part of the process requirements for processing equipment higher; not on-site production;

- The environmental performance of particleboard

- As the particleboard production process, the general use of formaldehyde-based adhesives, so its finished product will release more or less free formaldehyde

- According to the use of points: Class A particleboard; Class B particleboard

- According to the manufacturing method points: flat pressure particle board; squeeze particleboard.

- What are the raw materials for making the particleboard?

- In addition, non-wood materials such as plant stalks, seed shell skin can also be made of plate, the name is often known as the name of the material used,

- Some of advantages of particleboard

- particleboard in the production process, with a small amount of plastic, environmental protection coefficient is relatively high.