High Purity Calcium Silicate Board Price

- Loading Port:

- Lianyungang

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

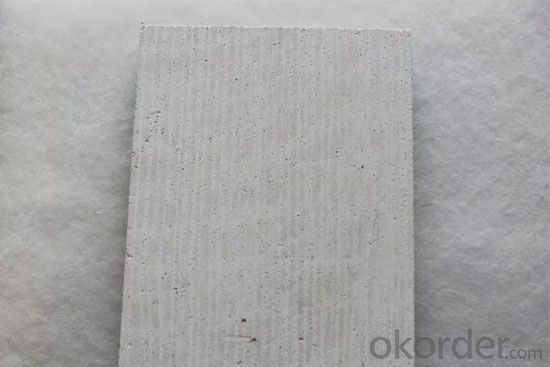

(Raw materials: pure quartz powder, quick lime, calcium silicate, plant fiber and many fined mineral stuffing including dispersant and additive) into a wet sheet and then through high temperature and high pressure autoclave for more than 10 hours by advanced technology. That it will compose a special calcium silicate board. There is no asbestos, brucite and meerschaum in the raw materials and the formulations at all.

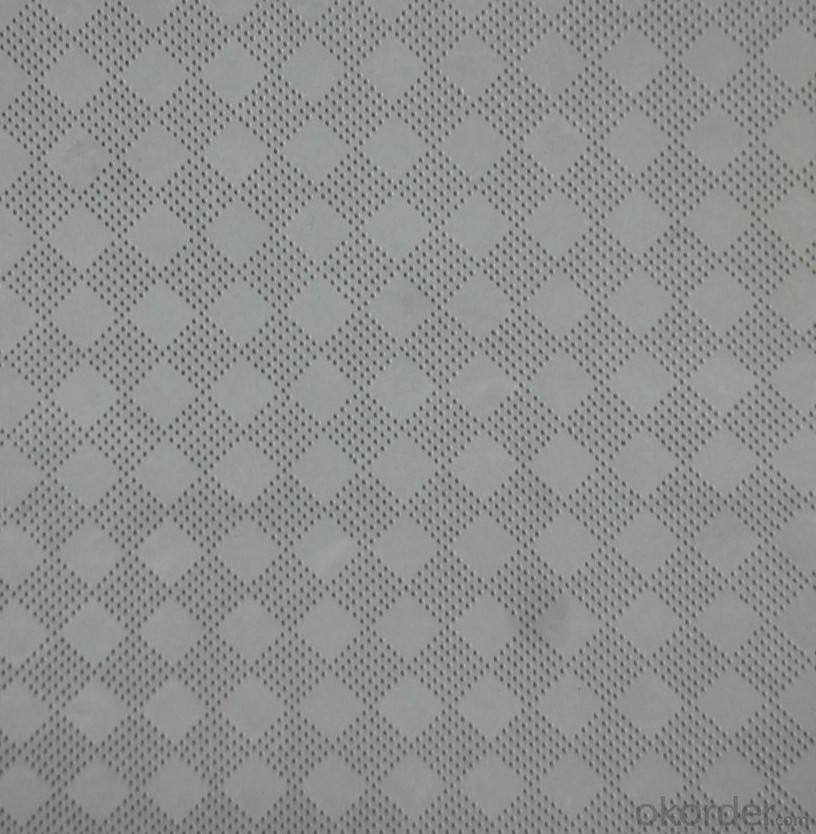

Product Applications:

1.Indoor ceiling of industrial and resident building.

2.Partition of industrial and resident building.

3.The ceiling and partition of the bathroom and other wet condition building.

4.Indoor ceiling and partition as base board of the decoration for operation room,clean room of hospital or laboratory .

5.The fireproof board of the air passage.

6.Furniture or furniture's accessories.

Product Advantages:

1. 100% asbestos free, environmentally friendly

2. Non-combustible Class A, does not release poisonous gas.When in contact with fire, smoke index is zero.

3. Light weight and high intensity, helps reduce the cost of building Based on stone crystal, best stability and not affected from temperature.

4. Good performance in heat preservation and insulation mildew proof and moth proof.

5. 100% asbestos free

6.Low thermal conductivity

7.Good compression strength

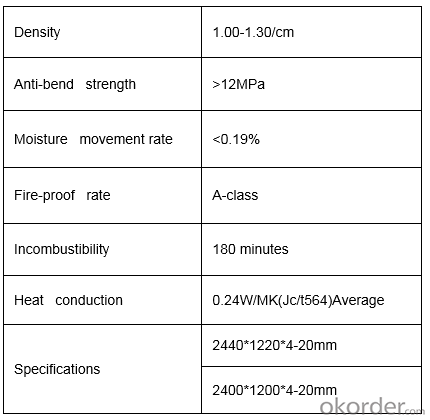

Main Product Features:

100% asbestos-free

Product composition: Portland cement, highly pure quartz sand, cellulose fiber

Density: 1.1-1.4 g/cm3

Water absorption: ≤30%

Moisture interference degree: 0.27mm

Moisture content: ≤10%

Swelling: ≤0.25%

Dry shrinkage rate: 0.5%

Impact resistance: ≥2.0 KJ/m2

Flexural resistance: ≥12 KJ/m2

Thermal conductivity: ≤0.2 W(M.K)

Screw-pull force: ≥75 N/mm

Frost resistance: After 25 freeze-thaw cycles without rupture and layer phenomena.

Product Specifications:

FAQ:

1:.How can I get your prompt quotation?

A: we can give you reply with quotation quickly if you kindly send the inquiry with following factors: working temperature, bulk density, dimension (length*width*thickness), and quantity.

2.What's the MOQ of the order?

No limit, we can offer the best suggestions and solutions according to your condition.

3. Which payment terms can you accept?

T/T,LC,Western Union,moneygram are available for us.

4. After an order is placed, when to deliver?

15-25days after confirming the order.

5. Does your company accept customization?

We accept OEM service.

6. How to solve the quality problems?

If the products don’t conform to customer’s samples or have quality problems, our company will be responsible to make compensation for it based on enough evidence.

Images:

- Q:Calcium silicate board is not gypsum board?

- Now the new situation, the gypsum board market has become smaller and smaller, calcium silicate board market share and customer recognition rate increased year by year, the corresponding calcium silicate board manufacturers are also increasing, how to choose the right price, good quality silicon Calcium carbonate board it, it is recommended that you visit Shandong Lutai building materials to look at

- Q:Toilet with silicon calcium board ceiling, with the general opening device can not open

- It is recommended that you build a drill bit yourself. (At least two), cut it off, leaving about 2 cm (the thickness of calcium silicate board should be less than 2 cm) length, it is welded in a 5mm thickness of the iron plate, The distance between the two drill bits can be determined according to the size of your opening diameter, the middle of the welding should also be a section of about 3 cm length of the impact drill bit as the center of the use of positioning with the use of speed switch with the drill, To slow the way after the operation can be.

- Q:Calcium silicate board bathroom can be used directly

- Followed by the use: calcium calcium board is mainly used for indoor ceiling, and it also high-grade, mid-range, low-grade distinction, the best is solid silicon calcium board, moisture, fire, pollution, low carbon, clean surface, durability it is good.

- Q:FC and calcium silicate board which is good

- FC board and calcium silicate board process is different from the use of the same, the price is basically the same. Each board to see where the use of performance which board, including the density, technical indicators are different, there is a big difference.

- Q:Tempered glass backdrop and calcium silicate board background wall which is better?

- Everything is good, but let me choose. I think the tempered glass wall is better.

- Q:What is the calcium silicate board, what is the use

- Construction of ceiling ceilings and partitions, home decoration, furniture liner, billboard liner, ship compartment board, warehouse floor, network floor and tunnel and other indoor works of the wall.

- Q:What is calcium silicate board?

- Part of my finishing part of the hair you see: fiber reinforced calcium silicate board (referred to as calcium silicate board) is inorganic mineral fiber or cellulose fiber and other loose fiber as a reinforcing material to calcium - siliceous material as the main cementing material , By the pulp, into the blank and high pressure steaming and other processes made of new environmentally friendly energy-saving sheet.

- Q:What is the difference between perforated calcium silicate wallboard and gypsum board?

- Silicon calcium board was first used in high temperature furnace insulation. Such as "in order to improve the quality of shaft kiln clinker material, easy to coal blending and reduce clinker burning coal consumption, we must strengthen the kiln kiln body insulation.Often the practice is to use the internal insulation method, refractory layer, the total thickness of the insulation layer should be ≥ 650mm, near the kiln wall should be added ≥ 60mm calcium silicate board or aluminum silicate fiber mat ".

- Q:Autoclaved aerated concrete slabs and fiber reinforced calcium silicate boards which are good

- Not the same use, bad comparison, calcium silicate board to do the surface decoration materials used

- Q:What is the thermal conductivity of calcium silicate board?

- Calcium silicate board composition: low alkali cement + high purity quartz sand + perlite and other mineral fillers + plant fiber + amount of mica

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Purity Calcium Silicate Board Price

- Loading Port:

- Lianyungang

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords