Rebar Stirrups

Rebar Stirrups Related Searches

Hot Rolled Steel Blue Steel Rebar Aisi 1020 Hot Rolled Grade 80 Rebar Rebar Lengths Standard Rebar 10Mm 30M Rebar T10 Rebar Rebar Identification 18J RebarHot Searches

12Mm Mdf Price Hot Rolled Steel Price Hot Rolled Steel PricesRebar Stirrups Supplier & Manufacturer from China

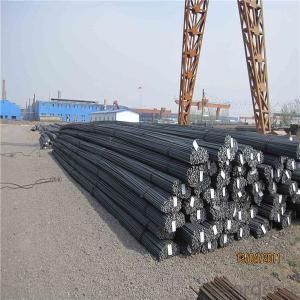

Okorder.com is a professional Rebar Stirrups supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Rebar Stirrups firm in China.Hot Products

FAQ

- Carbon steel and stainless steel rebars are both types of steel reinforcement used in construction, but they have distinct differences in composition and properties. Carbon steel rebars are made from a combination of iron and carbon, with small amounts of other elements such as manganese and copper. The carbon content in these rebars typically ranges from 0.15% to 0.60%. Carbon steel rebars are strong, durable, and cost-effective. They have good tensile strength, which is crucial for reinforcing concrete structures. However, they are susceptible to corrosion if not properly protected, especially in environments with high moisture or exposure to chemicals. On the other hand, stainless steel rebars are made from a combination of iron, chromium, nickel, and other alloying elements. The chromium content in stainless steel is typically above 10.5%, which creates a protective layer of chromium oxide on the surface of the rebar, preventing corrosion. Stainless steel rebars have excellent corrosion resistance, even in harsh environments with high humidity, saltwater, or exposure to chemicals. They are also highly durable and have high tensile strength, similar to carbon steel rebars. The main difference between carbon steel and stainless steel rebars is their corrosion resistance. Carbon steel rebars require proper protective coatings, such as epoxy or galvanization, to prevent corrosion. On the other hand, stainless steel rebars have inherent corrosion resistance due to the presence of chromium oxide layer, eliminating the need for additional coatings. Another difference is the cost. Carbon steel rebars are generally cheaper compared to stainless steel rebars. However, the total cost of a project should also consider the long-term maintenance costs associated with corrosion protection measures required for carbon steel rebars. In summary, carbon steel rebars are strong and cost-effective but require additional corrosion protection measures, while stainless steel rebars have excellent corrosion resistance and durability but come at a higher cost. The choice between the two depends on the specific project requirements, budget, and expected environmental conditions.

- Yes, steel rebars are suitable for use in aggressive environments. Steel rebars are commonly used in construction projects, including those in aggressive environments such as coastal areas, chemical plants, and wastewater treatment facilities. They possess excellent durability, strength, and corrosion resistance properties, making them highly suitable for withstanding aggressive elements like saltwater, chemicals, and moisture. Additionally, proper protective coatings can be applied to enhance their resistance to corrosion, ensuring their long-term performance in aggressive environments.

- To ensure safe and effective welding of steel rebars, there are several precautions that should be taken: 1. It is important to work in a well-ventilated area or use exhaust systems to remove harmful fumes and gases generated during welding. This helps maintain a safe breathing environment. 2. Welders should always wear appropriate personal protective equipment (PPE) such as a welding helmet or face shield, safety glasses, welding gloves, flame-resistant clothing, and steel-toed boots. This protective gear minimizes the risk of burns, eye injuries, and other physical hazards. 3. Fire prevention is crucial. Before starting the welding process, ensure that the work area is free of flammable materials and have a fire extinguisher nearby. It is also advisable to have a fire watch person present to monitor for potential fire hazards. 4. Proper grounding is essential to prevent electrical shocks. Ensure that the welding machine is correctly grounded and the workpiece is connected to a reliable grounding point. 5. Clean the surface of the rebars before welding. Remove any oils, grease, dirt, or rust using a wire brush or grinder, as these contaminants can affect the weld's quality. 6. Employing the correct welding technique is crucial for strong and reliable welds. Follow recommended welding parameters, such as current, voltage, and electrode diameter, and maintain a steady hand and consistent travel speed to prevent weld defects. 7. It is important to have proper training and experience when working with steel rebars. Ensure the welder is skilled and knowledgeable in this area to minimize errors and meet required standards and specifications. By adhering to these precautions, welders can significantly reduce the risk of accidents, injuries, and subpar weld quality when working with steel rebars.

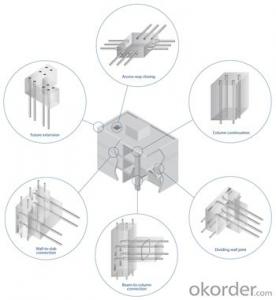

- Yes, steel rebars can be used in architectural concrete elements. They provide additional strength and reinforcement to the concrete structure, ensuring its durability and stability. Steel rebars are commonly used in architectural designs such as columns, beams, and slabs to enhance the overall structural integrity of the concrete elements.

- The bending capacity of steel rebars depends on various factors such as the diameter, grade, and reinforcement detailing. Generally, steel rebars have high bending capacity due to their inherent strength and ductility. However, the specific bending capacity can vary and should be determined based on engineering calculations and design standards.

- Indeed, steel rebars are a suitable option for hospital construction. Referred to as reinforcing bars, steel rebars are commonly utilized in construction projects to impart strength and stability to concrete structures. In the context of hospital construction, where safety and durability are of utmost importance, steel rebars offer numerous benefits. First and foremost, steel rebars possess remarkable tensile strength, enabling them to endure heavy loads and resist deformation. This attribute is critical in hospital construction, where the edifice must support the weight of medical equipment, patients, and other infrastructure. Furthermore, steel rebars bolster the overall structural integrity of the hospital, guaranteeing long-term stability and safety. Moreover, steel rebars exhibit excellent fire resistance properties. Hospitals are classified as high-risk establishments, as they house potentially flammable materials and electrical equipment. Steel rebars can endure high temperatures without compromising their strength, thus enhancing the structure's fire protection. Additionally, steel rebars are resistant to corrosion, shielding the concrete from damage caused by moisture and chemicals. Hospitals often experience elevated humidity levels and exposure to various chemicals employed in medical procedures. Through the utilization of steel rebars, the risk of corrosion and subsequent structural deterioration is minimized, ensuring a prolonged lifespan for the hospital building. Lastly, steel rebars are easily obtainable and cost-effective. Hospital construction projects frequently adhere to strict timelines, and the use of steel rebars enables efficient construction and swift installation. Furthermore, the market's abundance of steel rebars ensures competitive pricing, rendering them a cost-effective choice for hospital construction. In conclusion, steel rebars are unquestionably suitable for employment in hospital construction. Their high tensile strength, fire resistance, corrosion resistance, and cost-effectiveness render them an ideal selection for guaranteeing the safety, durability, and long-term stability of hospital structures.

- Steel rebars contribute to the load-bearing capacity of structures by providing reinforcement and strength to concrete. When embedded within the concrete, rebars increase its tensile strength, allowing it to withstand higher loads and prevent cracking or collapsing. This reinforcement enhances the overall structural integrity and durability of buildings, bridges, and other construction projects.

- The process of removing steel rebars from concrete structures involves several steps to ensure the safe and efficient removal of these reinforcement bars. 1. Assessment: Before starting the removal process, a thorough assessment of the concrete structure needs to be conducted. This includes evaluating the type and condition of the rebars, the integrity of the surrounding concrete, and any potential risks or obstacles that may affect the removal process. 2. Preparation: Once the assessment is completed, necessary preparations are made to ensure the safety of the workers and the surrounding environment. This may involve wearing personal protective equipment, setting up barricades or safety barriers, and securing the area to prevent any accidents or injuries. 3. Cutting: The next step is to cut the steel rebars. This can be done using various techniques such as oxyacetylene cutting, saw cutting, or using specialized cutting tools like rebar cutters or shears. The cutting method used depends on the size and thickness of the rebars, as well as the accessibility of the area. 4. Extraction: After the rebars are cut, they need to be extracted from the concrete structure. This can be done manually using pry bars or mechanical methods such as using cranes, excavators, or hydraulic breakers. The extraction process should be done carefully to avoid damaging the surrounding concrete or causing any structural instability. 5. Cleaning and Restoration: Once the rebars are removed, the area needs to be cleaned of any debris or leftover material. This is important to ensure a safe working environment for any subsequent construction or renovation work. Additionally, any damage caused to the concrete structure during the removal process should be repaired or restored to maintain its structural integrity. It is important to note that the process of removing steel rebars from concrete structures should be carried out by trained professionals with expertise in construction and demolition. It is also essential to comply with local regulations and safety guidelines to prevent accidents, minimize environmental impact, and preserve the integrity of the concrete structure.