Application Of Geomembrane

Application Of Geomembrane Related Searches

Shiny Or Dull Side Of Aluminum Foil For Cooking Inverter For 100w Solar Panel Solar Panel Inverter For Rv Pvc Tiles For Walls Wall Lights For Bedrooms Inverter Ac With Solar Panel Solar Panel With Inverter Kit Solar Panel Kits With Inverter Solar Panel With Inverter Direct Roving For PultrusionHot Searches

Type Of Inverter For Solar Price Of Shipping Containers For Sale Types Of Inverter For Solar Used Sandwich Panel For Sale Bags Of Cement For Sale Pvc Chairs For Sale Tilt Panel Props For Sale Types Of Temporary Side Panels For Cement Deck Cost Of Awnings For Decks Type Of Scaffolding With Pdf Price Of Scrap Stainless Steel Price Of Stainless Steel Scrap Price Of Stainless Steel Type Of Stainless Steel Types Of Stainless Steel Grades Types Of Stainless Steel China Aluminum Coil Factory pvc pipe manufacturers in usa Sandwich Panel Price In India Aluminum Corp Of China StockApplication Of Geomembrane Supplier & Manufacturer from China

Okorder.com is a professional Application Of Geomembrane supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Application Of Geomembrane firm in China.Hot Products

FAQ

- nan

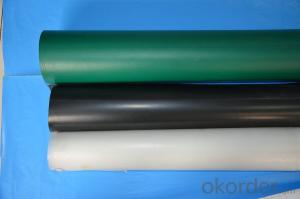

- The main mechanism of geomembrane construction site is to use imperviousness of plastic film to cut off earth dam leakage passage, and bear hydraulic?pressure and adapt to the deformation of the dam with greater tensile strength and elongation; and non-woven fabric is also a macromolecule staple fibre chemical material. The main mechanism of geomembrane construction site is to use imperviousness of plastic film to cut off earth dam leakage passage, and bear hydraulic pressure and adapt to the deformation of the dam with greater tensile strength and elongation; and non-woven fabrics is also a kind of macromolecule staple fibre chemical material, formed by needle punching or hot sticking. It has high tensile strength and extensibility, the combination with plastic film not only increases the tensile strength and puncture resistance of plastic film; and as a result of the rough surface of non-woven fabrics, it increases friction coefficient of contact surface, which is conducive to the stability of composite geomembrane and protective layers. At the same time, they have good corrosion resistance to bacteria and chemical action, erosion resistance to acid, alkali, and salt , and long service when keeping out of the sun.

- Geomembranes contribute to erosion control in mining reclamation projects by providing a protective barrier that prevents soil erosion and the subsequent contamination of nearby water bodies or ecosystems. These impermeable liners are used to line drainage channels, ponds, and landfills, effectively containing and preventing the escape of hazardous materials or sediments. By enhancing the stability of reclaimed land and reducing erosion, geomembranes play a crucial role in the successful restoration of mining sites and preserving the surrounding environment.

- nan

- What are the functions of reflective membranes? 1: Application of reflective membranes in highway traffic signs: Different signs made of reflective membranes in different grades are used in different driveways, according to different designed speeds. Usually reflective membranes with high retroreflection coefficient and strong reflective brightness are required to be used in driveways with fast designed speed (such as highway, expressway, arterial highway,etc); in some developed areas recently,road signs made of high grade reflective membranes are used in the urban roads, which are beautiful and safer; medium grade reflective membranes are usually used in roads with slow design speed, such as provincial and national highways; and some temporary signs usually use low grade reflective membranes. 2: Application of reflective membranes in license plates of vehicles: The vehicle license plates used in mainland China are type 92 plates,(the manufacturing techniques 1) paste flective membranes with good flexibility to the aluminum plates(usually use special reflective membranes for license plates), use special machine to stamp out number, and color the number with the silk screen printing technology, if the license plate is black on yellow, then black ink is colored on the yellow reflective membrane with the silk screen printing technology, numbers on such plates used the silk screen printing technology can not reflect light while the plates can.

- nan

- One is GB 1st type

- nan

- A, The laying of HDPE geomembrane. 1. Corresponding qualified check and acceptance documents are needed before paving HDPE geomembrane. 2. Before cutting HDPE film, accurately measure its relavant size, and then cut according to reality. It is not suitable to cut according to icon size. It should be numbered by sheet and recorded in detail on the special form. 3. There should be minimum welding line during paving HDPE geomembrane. Save raw material as much as possible on the premise of quality assurance. At the same time, it is easy to ensure quality. 4. The lap?width of seam among films is usually not smaller than 10cm. Make orientation of welding line parallel to maximum gradient, namely, arrange along the gradient direction. 5. The seaming length should be shortened at corner and deformed section. Except special requirements, gradient is over 1: Except special requirements, gradient is over 1: Except special requirements, gradient is over 1: Except special requirements, gradient is over 1:

- There are several advantages of using geomembranes in agricultural irrigation systems. Firstly, geomembranes prevent water seepage and leakage, ensuring that water is efficiently and effectively delivered to the crops. This helps in conserving water resources and minimizing water wastage. Secondly, geomembranes help in controlling weed growth by blocking sunlight and preventing weed germination. This reduces the need for herbicides and manual weed control, leading to cost savings and reduced environmental impact. Additionally, geomembranes provide a physical barrier that helps in maintaining soil moisture levels, preventing excessive evaporation and reducing irrigation frequency. This results in improved water efficiency and reduced irrigation costs. Lastly, geomembranes can be customized and tailored to specific field requirements, allowing for precise water distribution and reducing the risk of overwatering or underwatering. Overall, the use of geomembranes in agricultural irrigation systems offers significant benefits in terms of water conservation, weed control, improved water efficiency, and enhanced crop productivity.

- When selecting geomembranes for desalination plants, several factors need to be considered. These include the chemical compatibility of the geomembrane with the saline water and any chemicals used in the desalination process, as well as its resistance to UV radiation, punctures, and tears. The geomembrane's flexibility and ability to withstand temperature variations and potential settlement of the underlying soil are also important considerations. Additionally, factors such as installation and maintenance costs, expected lifespan, and environmental sustainability should be taken into account during the selection process.

- Geomembranes are tested for tear resistance through various methods, including the trapezoidal tear test and the tongue tear test. These tests involve applying controlled forces to the geomembrane samples to measure their ability to resist tearing and provide valuable information about their durability and quality.