LDPE Geomembranes with Thickness of 1.0mm

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

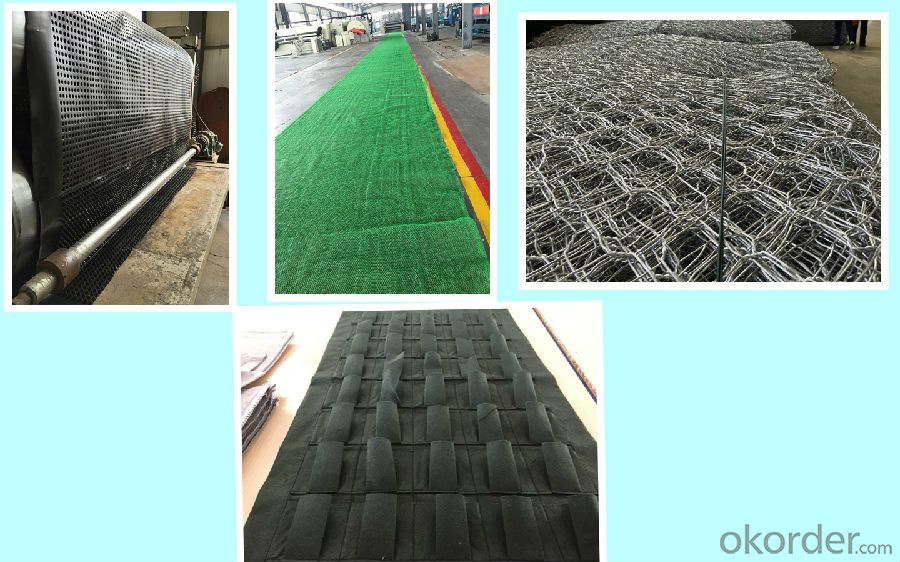

LDPE Geomembranes

Products Description

Made from LDPE, LLDPE, EVA resin and additives such as antioxidant, carbon black, master batch etc with the method of 1 layer extrusion and 3 layers co-extrusion in high temperature.

Product Application

1. Agricultural water conservancy projects.

2. Ponds for aquaculture.

Product Advantages:

1. High flexibility, high waterproof coefficient.

2. Could be used in the temperature of -70 ℃~110 ℃.

3.Good stability, anti acid and alkalis,anti-erosion.

4.High climate bearing ability, excellent in anti-aging.

5.High tensile strength and elongation, can be used in bad geology and climate, especially be used in the soil uneven sedimentation.

6.High friction coefficient.

Product Specification

1. Thickness: 0.1mm to 3.0mm.

2. 4m-9m in roll width, roll length as design or client's request.

Products Characteristics

1.HDPE performs well in mechanical properties ,ageing-resistance , chemical-resistance ,climate- resistance and resistance to puncture .

2.LDPE & EVA feathers great elongation, good flexibility at low temperature, softness and easy installation.

3.ECB ,high-class waterproofing rolls, is formed by combining ethylene polymer with oil-resin.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are freee, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

- Q:What is the role of the geomembrane?

- The main mechanism of geomembrane construction site is to use imperviousness of plastic film to cut off earth dam leakage passage, and bear hydraulic?pressure and adapt to the deformation of the dam with greater tensile strength and elongation; and non-woven fabric is also a macromolecule staple fibre chemical material. The main mechanism of geomembrane construction site is to use imperviousness of plastic film to cut off earth dam leakage passage, and bear hydraulic pressure and adapt to the deformation of the dam with greater tensile strength and elongation; and non-woven fabrics is also a kind of macromolecule staple fibre chemical material, formed by needle punching or hot sticking. It has high tensile strength and extensibility, the combination with plastic film not only increases the tensile strength and puncture resistance of plastic film; and as a result of the rough surface of non-woven fabrics, it increases friction coefficient of contact surface, which is conducive to the stability of composite geomembrane and protective layers. At the same time, they have good corrosion resistance to bacteria and chemical action, erosion resistance to acid, alkali, and salt , and long service when keeping out of the sun.

- Q:What are the uses of glass films?

- The surface of the glass is not easy to be scratched, and should be pasted by the proffesional personnels. It is easy to appear bubbles and affect the beauty of the appearance.

- Q:How do geomembranes help in liquid containment?

- Geomembranes help in liquid containment by providing a barrier that prevents the liquid from leaking or infiltrating into the surrounding environment. They are impermeable and durable, effectively sealing off the liquid and ensuring its containment. Additionally, geomembranes can be customized to suit different applications, such as in waste management, agriculture, or mining, offering a versatile solution for liquid containment needs.

- Q:What are the advantages of high density polyethylene HDPE geomembrane ?

- Seamless sweat soldering is ok, water proof anticorrosion, long service life.

- Q:Generally, how many welding rods are needed when welding the impoted geomembrane of ten thousand square meters?

- If the construction surface is flat and open with few turns and dead angles, then the welding rods will be saved. The creeping welding machine will not use welding rods on the flat surface. The welding rod is used in uneven surface on which creeping welding machine can not be used.

- Q:What are the differences between reflective paint and reflective membranes?

- Generally, reflective membrane includes following grades, advertising grade, engineering grade, high intensity grade, diamond grade and so on. Reflective stickers are mostly made of reflective prismatic sheetings.

- Q:Can geomembranes be used in decorative landscape designs?

- Yes, geomembranes can be used in decorative landscape designs. They can be used as liners for ponds or water features, as well as for retaining walls or raised garden beds. Geomembranes provide a barrier against water leakage and can help maintain the integrity and aesthetics of the landscape design.

- Q:What are the specifications of plastic film

- 1 appearance. Should be smooth, bright, uniform thickness, transparency. Does not allow to have the obvious "watermark" or piece of "cloud" formated on the surface of the film because of the low processing temperature of the raw material resin is not sufficient plasticization, Bubble, perforation and rupture are not allowed. Impurities that exceed 0.6mm are not allowed . Not allowed to have 2mm or more of the particle size and bulk material due to the formation of the resin. Does not allow a clear "stripe" exists, not obvious "stripes" refers to the hand at room temperature to tear (two thumb distance LCM, similar to the pull cloth posture), when the tear was zigzag, should not be a straight line. Allows a small amount of live fold to be inserted and folded neatly (in order to form a bundle of thin film coils). 2 film should be kept in a cool and dry room, not to squeeze as far as possible , away from the heat source or less than 1m, the effective quality assurance period of one year. 3 width (fold diameter thin film width, unriven at double) greater than 1500mm film thickness deviation of plus or minus 0.005mm allows ultra width of 20mm, and the kind of not more than two. The thickness of not less than 0.08mm.

- Q:Should geotextile be laid under the geomembrane in the fish or shrimp ponds?

- It is unneccessary. Now the technology of geotextile is mature, so the quality of it will not be too bad. Paying great attention to the brand is also completely unnecessary. I would ask do you check the brand when buy pork? No. All pork is bought from the pork satll. There are only two possibilities when you attach too much importance to the brand. 1 you are advertising for yourself. 2, you do not understand the market. I suggest you buy it in the nearnest shop.

- Q:What are the challenges of installing geomembranes in remote locations?

- Installing geomembranes in remote locations can pose several challenges. Firstly, accessing these remote sites can be difficult, often requiring long and arduous journeys through rough terrains or limited transportation options. This can lead to logistical complications and increased costs for transporting equipment and materials to the site. Additionally, remote locations may lack proper infrastructure and facilities, making it challenging to set up temporary camps or provide necessary resources for the installation process. Limited availability of skilled labor and technical expertise in these remote areas can also hinder the installation process. Lastly, extreme weather conditions and unpredictable environmental factors can further complicate the installation, requiring additional precautions and measures to ensure the effectiveness and longevity of the geomembrane.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

LDPE Geomembranes with Thickness of 1.0mm

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords