XL Series Sand Washing Machinery for Sale

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 15 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

XL Series Sand Washing Machinery is generally used to clear up and remove the dirt and contaminate mixed in sandstones. Novel sealing structure, adjustable overflow weir and reliable transmission system could fully ensure the complete washing and dehydrating. It is suitable for washing fine granularity and heavy granularity, and frequently used in industries in need of sand including highway and constructions.

Description of XL Series Sand Washing Machinery

XL Series Sand Washing Machinery is widely used for distributing ore in the close circuit with ball mill, grading ore and fine slit in the gravity mill, grading granularity in the flow of metal ore-dressing and desliming and dehydrating in the washing. Advantages are simple structure, reliable working condition and convenient operation. According to the principle that different grains are with different specific gravity and sedimentation rate in the liquid, the fine ore flows in the water and the coarse ore sinks in the bottom. The classifier that has machine grading by discharging from the top can filtrate the materials and send coarse materials to the feeding mouth and discharge the fine material from the pipe. The seat of the machine adopts channel steel and body adopts armor plate and the spiral axle adopts cast iron, so it’s durable. The lifting equipments have two types, by electricity and hand.

Working principle of XL Series Sand Washing Machinery

The XL Series Sand Washing Machinery eliminate the impurities by the buoyancy of water ,as we all knew the specific gravity of various materials are different ,so when XL Series Sand Washing Machinery on operation , the spiral scatters will rotating , the strength of rotating spiral scatters will push the water going forward , at the same time , the light specific gravity which is mean the impurities will flowing with water , but the clear sand mater will fell down and going forward also by the strength of spiral scatters .this the way how XL Series Sand Washing Machinery doing .

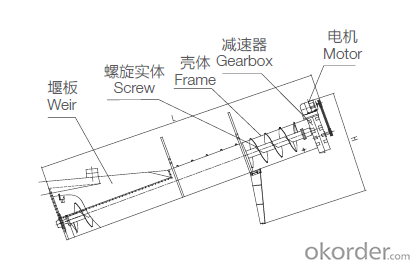

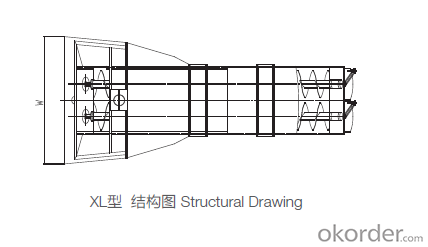

Consist of XL Series Sand Washing Machinery

The XL Series Sand Washing Machinery consist of cell body, speed reducer ,motor power ,central shaft, spiral scatters, support parts.Sentai Mining Factory is the real good producer of XL Series Sand Washing Machinery,which has years experience of how to producing the quality XL Series Sand Washing Machinery with stick steel plate . We can supply almost all the machine which connecting with beneficiation .

Our main product :hammer crusher , rotary dryer ,ball mill ,magnetic separator ,flotation separator .

Sand Washer Technical Parameters

| Model | Screw Diameter (mm) | Tub Length (mm) | Selected Granularity (mm) | Processing Capacity (t/h) | Screw Speed (r/min) | Motor Power (kw) | Water Consumption (t/h) | Overall Dimension (L×W×H) (mm) | Weight (t) |

| XL915 | 915 | 7585 | ≤10 | 60-100 | 21 | 11 | 60-80 | 8500×2810×3600 | 6.27 |

| 2XL915 | 915 | 7585 | ≤10 | 120-200 | 21 | 2×11 | 120-160 | 8420×3765×3960 | 11.11 |

| XL1115 | 1115 | 9782 | ≤10 | 100-175 | 17 | 18.5 | 100-150 | 10970×3945×4720 | 10.7 |

| 2XL1115 | 1115 | 9782 | ≤10 | 200-350 | 17 | 2×18.5 | 200-300 | 10970×5250×4720 | 17.94 |

| XS2610 | 2600 | 3220 | ≤10 | 30-50 | 1.2 | 5.5 | 25-40 | 3220×2125×2670 | 3 |

| XS3016 | 3000 | 3810 | ≤10 | 50-80 | 1 | 15 | 40-60 | 3800×3 |

- Q:I am a foreign customers want to recycle sand washing machine out of mud containing 90% of fine sand, and to dry out 85% of the water, and ask the relevant manufacturers

- You can go to the Nanchang Changjiang CISCO Mining Machinery Co., Ltd. official website on the understanding, may be able to meet the requirements you need.

- Q:Cobble stone production line equipment is a how much money

- Sand gravel by equipment set hopper, feeder, crusher, crusher, vibrating screen, sand making machine, sand washing machine, conveyor. Of course, it can be simplified.

- Q:I want to contract a sand and gravel factory, but I am a layman. I don't understand anything. Please help my brother and give some advice

- I am specially engaged in the management of the crushed stone factory. According to the installation, maintenance and design, the crushed stone factory must do every detail

- Q:How many kinds of belt are there in the sand washer?

- The bottom of the trough is semicircular and is fed by the lower end, and the discharge port is arranged at the bottom of the upper groove. Operation of sand washing machine, sand grinding by rod mill or by sieve screen sand material from the feed inlet water sand washing machine, coarse particles sink at the bottom of the groove by a spiral conveying to the upper end of the outlet, and then use the belt conveyor sent. During the settlement process, the fines, fines and impurities contained in the sand are washed with water and discharged by the overflow weir at the bottom of the tank. The sand washing machine is a kind of mining machine for shaping products. It is used for washing and washing of sand materials in the construction of water conservancy projects.

- Q:Bucket sand washing machine production line, large sand washing picture, wheeled sand washing machine how to wash sand?

- Sand washing machine [sand washing machine] is widely used in metallurgy, building materials, hydropower and other industries cleaning, grading, impurities and other operations of fine-grained and coarse-grained materials, washing operations. Construction sand, gravel, roads are still in proper use. The sand washing machine has the advantages of reasonable structure, convenient maintenance, large amount of power consumption and little cleaning. The new sealing structure, all closed oil bath type transmission device, adjustable overflow weir plate, to ensure that the product's efficiency, durability, cleaning, dehydration effect, fine products remain stable, and so on a variety of industries.The sand washing machine has the advantages of simple structure, the impeller drive bearing device with water and the water isolation material, greatly avoid the bearing due to flooding, sand and pollutants caused damage of the phenomenon; the machine is used for sand and gravel sand washing with traditional spiral sand washing machine has obvious advantages compared to the following: (1) fine sand and powder loss, wash the sand distribution and fineness modulus of sand for building "national", "construction of pebble and gravel" standard; (2) aircraft in addition to the screen almost no wearing parts; (3) the service life is long, long without maintenance.

- Q:The difference between spiral and spiral sand washing machine washing machine where?

- Their use is different, so that their names will be different. Take the most simple, sand washing machine drum and drum washing machine, the two kinds of machinery in fact are basically the same, but the drum washing machine cleaning effect than stone sand cleaning effect is good, so in this case, you can call the washing machine. Because of its appearance and principle, also known as the spiral drum washing machine, washing machine, water washing machine, washing machine vibration etc.. Used in construction sites, sand plants, prefabricated plants and hydropower sites, a large number of gravel desliming, screening operations, can also be used for ore sorting operation of the machine.

- Q:What kind of equipment is sand washing machine?

- Powder sand in the construction engineering application has been more and more widely, as a kind of new building material, to replace the ordinary river sand to protect the ecological environment and promote the development of circular economy has made important contributions, a kind of special equipment of our Shandong Tai'an Guangtong machinery production of powder sand washing machine is the production of powder sand.

- Q:If only river sand is washed, is it possible to use only bucket sand washing machines? How many square meters does a set of equipment cover?

- The bucket type sand washing machine mainly cleans the dust above the stone, and the spiral sand washing machine mainly aims at cleaning the soil above the stone

- Q:Is sand making machine good for single motor or double motor?

- Double motor, because now most of the sand machine is equipped with two different crushing mechanism (that is, hammer or cage), a motor is not enough.

- Q:Structure features of sand washing machine

- Bearings and water, materials separately, to avoid premature damage caused by rust caused by pollution.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

XL Series Sand Washing Machinery for Sale

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 15 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords