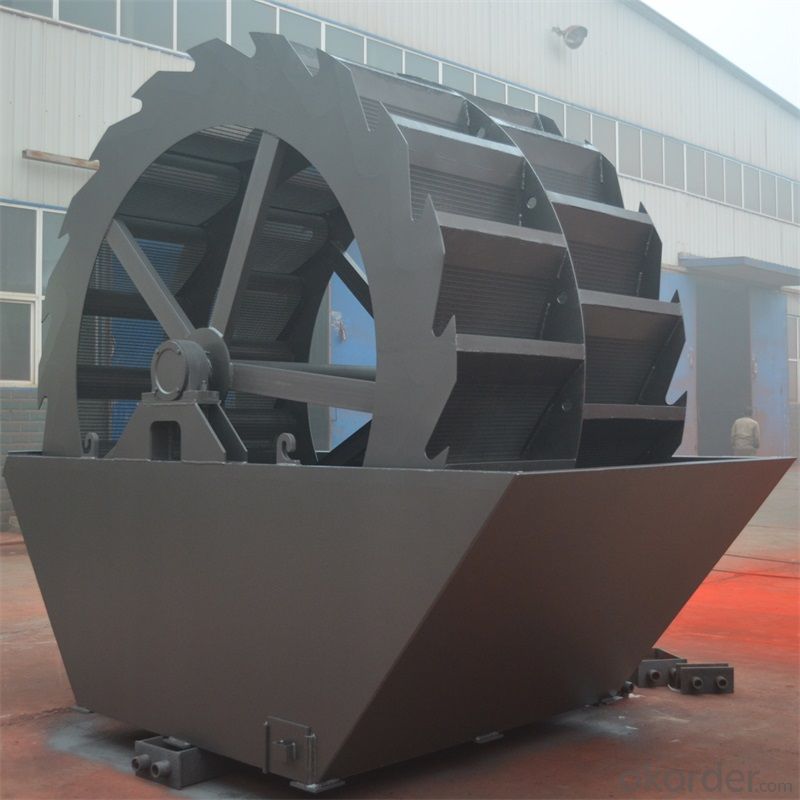

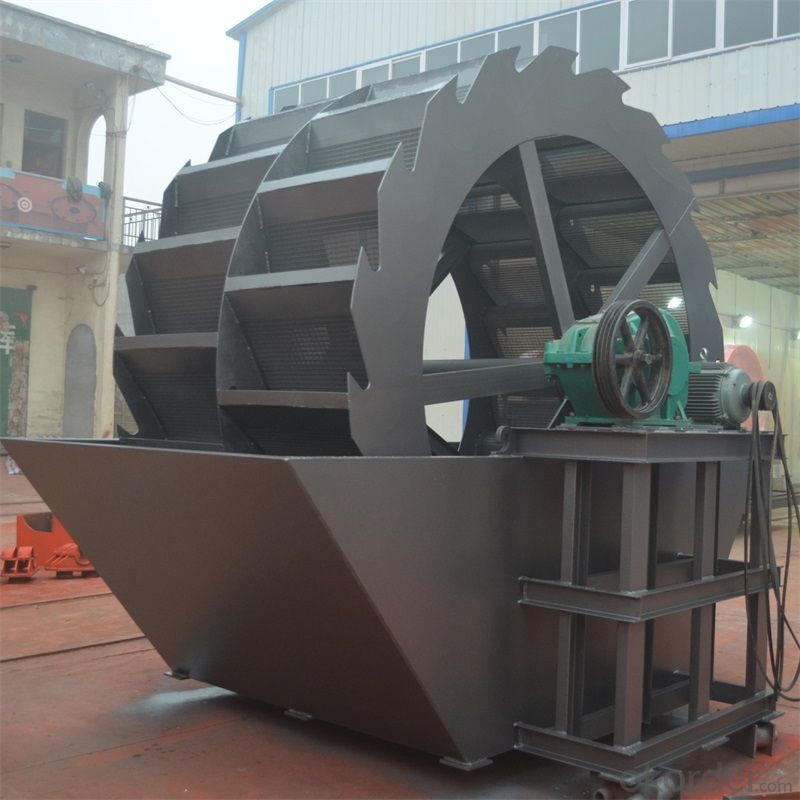

Sand washing machine|Wheel Dou type sand washer|Sand washing machine

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 99 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Product introduction:

XS series sand washer is my company USES advanced technology at home and abroad, in combination with the practical situation of domestic sand industry development and production with sand making machine use efficient bucket wheel sand washing equipment, this equipment combined washing, dehydration, grade three functions, the machine during the process, used to wash the sand in the mixed soil, dust, etc., to achieve the purpose of clean sand, can also be used in mineral processing operations such as sand or similar process, the yield can be up to 600 t/h.

Application field:

XS series sand washer is widely used in metallurgy, building materials, water and electricity station, glass manufacturing, and the development of the well used in industries such as washing, grading, and the work, such as removing impurity is suitable for washing of fine-grained and coarse-grained materials, the building sand, sand road use, is appropriate.

Structure principle:

Sand washing machine work, motor through the triangle, reducer, gear reducer drive slowly rotating impeller after sand by feeding trough into the basin, under the drive of the impeller, and mutual grinding, remove cover impurity on the surface of the sand and gravel, and destruction of the coated sand moisture layer, favors the dehydration; Add water at the same time, form a strong current, to take away impurities and the proportion of small foreign body in time, and from the spillway trough eduction, complete the cleaning effect. Clean sand by the leaves away, and finally into the sand from rotating impeller discharge chute, complete sand cleaning effect.

performance:

1、XS series sand washing machine has reasonable structure, large capacity, high clean, low consumption, reducing the cost of sand characteristics, especially the moving parts, impeller drive bearing device with water and water material isolation, accurately separated sand and water, greatly avoid the bearing damage caused by flooding, sand and pollutant phenomenon occurs, compared with the traditional mechanical, greatly reduce the failure rate, is the first choice of system of domestic sand industry upgrading.

2、Reasonable structure and novel sealing structure, fully enclosed oil valley type gear, adjustable overflow weir plate, ensure the series product is efficient and endurable, their cleaning, their dehydration effect is good, fine products remain stable.

Technical Data

| Model | Impellerdia(mm) | Feedingsize(mm) | Capacity(t/h) | Power(KW) | weight(kg) | Dimension(mm) |

|---|---|---|---|---|---|---|

| XS2615 | 2600×1500 | ≤10 | 30-80 | 7.5 | 2700 | 3320×2200×2670 |

| XS3016 | 3000×1600 | ≤10 | 80—160 | 18.5 | 4300 | 4500×3206×3480 |

| XS3500 | 3500×1000 | ≤10 | 120—600 | 11 | 9900 | 4420×2930×3800 |

- Q:Which brand of wheel bucket sand washing machine is better?

- The machines have been made very early, and the durability and detail of the machine have been well done. And their washing machine model all, sand washing effect is good.

- Q:The working principle of sand washing machine

- The wearing parts are less consumed and the cost is low. The sand washing machine was reformed from coal washing machine. There are great limitations! The market for multi-function sand washing machine equipment will replace the traditional backward washing sand way. Will lead the market in the future!

- Q:Long heavy sand washing machine to teach you how to install and operate?

- Washing machine operation process:Step 1: raw material storageStorage of raw materials for general storage hopper, the hopper can be ZL50 loader feeding, feeding bucket mouth width should be greater than 3 meters, depending on the material hopper capacity of loader height, height, angle of gravity transportation of raw materials, the bigger the better.The second step: raw material transportationRaw materials conveyor belt conveyor generally, depending on the raw material containing mud, bucket mouth is best equipped with throttling device, has controlled the amount of cleaning. As a result of the raw material provided by the quarry, the dirt on the stone is not large and the adhesion is small, so the cleaning process is not too long,The third step: cleaningThe key is that when the stone is finished cleaning, do not add the tank, the viscera and the water, and form the two pollution of the stone.The fourth step: finished material deliveryThe complete cleaning stone is generally through belt conveyor to finished product storage or storage hopper use, so it is best to do the processing or storage and wash the.

- Q:First test the machine with sand washing machine, then wash the sand in the screw washer, right?

- Lark machine believes that this order depends on the extent of sediment sediment, if the sediment content of the mud is too large

- Q:What items should we pay attention to in the construction of sand aggregate production line?

- Large and medium-sized hydropower stations are generally located in the alpine gorge area. The lack of natural sand or reserves of local natural sand can not meet the needs of a large number of concrete aggregate in hydropower projects. Therefore, in the construction of large hydropower projects, such as the Three Gorges, Longtan, Xiaowan, Jin Anqiao, Xiangjiaba, Xiluodu and Nuozhadu Hydropower Station project, Jinping, the owners of the artificial aggregate system...

- Q:What should be paid attention to during the operation of sand washing machine in machine-made sand equipment?

- Sand washing machine is the main equipment in the sand to clean the sand in the dirt and debris, sand washing machine has a lot of details need attention during the operation, if the operator heard rapping or ammeter show when overloading, should immediately stop, until the machine stops, remove foreign bodies and check all relevant rotating parts is damaged. To confirm the normal, can only continue to start feeding. Especially for the sand processing plant has just been put into operation is more should pay more attention to the details, only correct carefully not to cause the production of sand washing machine malfunction, and correct careful operation can improve the quality of the sand note, let's take a look at the Red Star Machinery Manufacturing Co. Ltd is a professional production and technical personnel for the sand washing machine sand washing machine introduce the details of the operation.

- Q:What are the routine maintenance and performance features of the sand washing equipment?

- During the use of the sand washing machine, special technical personnel should be responsible for taking care of it, and operators must have certain techniques. Before the sand washing machine is installed, the operator must be trained in technical operations to understand the principles and performance of the sand washing machine and to be familiar with the operating procedures;4, equipped with necessary maintenance tools, as well as lubricating oil and corresponding parts.

- Q:Bucket type sand washing machine for hire

- The sand washing machine has the advantages of reasonable structure, convenient maintenance, large processing capacity, small power consumption, high cleaning degree, high efficiency and durability, good cleaning and dewatering effect, and fine particle product keeping.

- Q:The technological process of quartz sandstone

- Large granular stone (overtails) by belt conveyor to vertical impact crusher (sand making machine) for crushing, fine crushing stone by belt conveyor again into the sieve screening, thus forming a closed loop several times.

- Q:How to avoid gear damage when using sand washing machine?

- Is to do routine maintenance work, a little find wear and tear, to timely maintenance and maintenance;

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Sand washing machine|Wheel Dou type sand washer|Sand washing machine

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 99 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords