Widely Used Color Coated Steel Coil/Al-Zn Steel Coil/PPGI

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1.Application:

Construction | Outside | Workshop, agricultural warehouse, roof panel, wall panel in steel structure in warehouse,corrugated roof, roller shutter door, rainwater drainage pipe, retailer booth |

| Inside | factories exhibition hall,doorcase, light steel roof structure, folding screen, elevator, stairway | |

Electrical appliance | Refrigerator, washer, switch cabinet, instrument cabinet, air conditioning, micro-wave oven, bread maker | |

Furniture | Central heating slice, lampshade, chifforobe, desk, bed, locker, bookshelf | |

Carrying trade | Exterior decoration of auto and train, clapboard, container, isolation lairage, isolation board | |

Others | Writing panel, garbage can, billboard, timekeeper, typewriter, instrument panel, weight sensor, photographic equipment | |

2.Features:

With excellent cold-rolling steel strips as base material, it has the advantages of

.Good manufacturing performance

.High impact resistance

.Uniform plating thickness

.High adhesive force

.No peeling after forming

.High corrosion resistance

3.Details:

Base Material | Al-Zn Galvanized Steel Coil.SGLCC |

Top Side | 15-25 microns |

Back Side | 5-8 microns |

Width | 700-1250mm |

Thickness | 0.3-1.0mm ,thickness tolerance: +/- 0.02mm |

Al-Zn Coating | 30-150g/sq.m |

Spangle | Regular/Zero/Big |

Color | All RAL Color,or be customized |

Coil ID | 508mm&610mm |

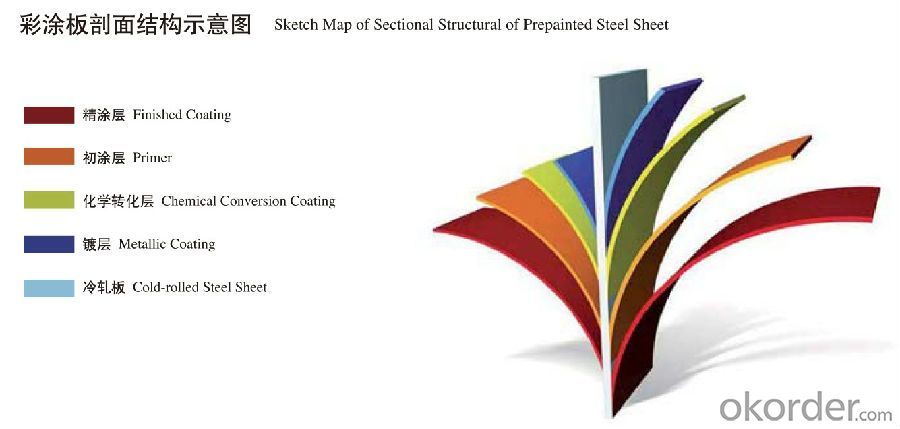

4. Images of steel coils:

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your Warranty?

Warranty: 1-Year for the whole light. Warranty is based on correct storage, installation, using and maintenanc

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q:How are steel coils used in the manufacturing of construction equipment?

- Steel coils are used in the manufacturing of construction equipment as they serve as a primary raw material for the fabrication of various structural components such as frames, bodies, and chassis. These coils are typically processed through cutting, bending, welding, and shaping techniques to create the necessary parts that provide strength, durability, and stability to construction machinery.

- Q:I want to know what to my wash stainless fridge door with before applying the stainless steel polish.

- Tips For Cleaning Your Stainless Steel No matter if you are in an industrial kitchen or just your household kitchen, maintaining the look and the cleanliness of your stainless is essential. There are plenty of products on the market that claim to be able to help you, but you can also do just as good with just knowing how to handle it. Stainless steel is difficult to clean because streaks and fingerprints show up easily. It is easier to see grime, grease and fingertips on stainless than on windows. To help you to keep your stainless steal countertops, utensils and appliances clean, follow these basic rules of thumb. Much more at web page!!

- Q:For my homework we have to fill out a table, but I cannot find some basic uses of these types of steel anywhere:Low carbon steel (iron mixed with lt;0.25% carbon)High carbon steel (iron mixed with lt;1.5% carbon)Stainless steel (iron mixed with nickle an chromium)Titanium steel (iron mixed with titanium)Manganese steel (iron mixed with manganese) Thanks :)

- Low okorder / You say you cannot find there uses anywhere. These all came up using the simplest of web searches. You really need to have a word with your IT teacher as clearly you are not doing basic searches properly.

- Q:How is the quality of steel coils determined?

- The quality of steel coils is determined by various factors such as the chemical composition, mechanical properties, surface finish, and dimensional tolerances. These factors are assessed through rigorous testing and inspections, including chemical analysis, tensile testing, hardness testing, visual inspection, and dimensional measurements. Additionally, industry standards and specifications play a crucial role in determining the quality of steel coils by setting specific requirements that the coils must meet.

- Q:What are the challenges in coil recoiling for high-strength steel?

- There are several challenges associated with coil recoiling for high-strength steel. Firstly, high-strength steel is known for its increased hardness and strength, which makes it more difficult to coil compared to regular steel. The higher tensile strength of high-strength steel puts more stress on the recoiling equipment, leading to potential damage or failure of the machinery. Secondly, high-strength steel tends to have lower ductility, meaning it is less able to withstand deformation without fracturing. Recoiling high-strength steel coils requires careful handling and control to prevent any excessive bending or stretching that could cause the material to break or crack. Another challenge is the shape memory effect of high-strength steel. This phenomenon causes the material to return to its original shape after being deformed. While this property can be advantageous in some applications, it complicates the recoiling process as the steel coil may resist being reshaped into a new coil form. Furthermore, high-strength steel often has a more complex microstructure compared to regular steel, with different phases and grain boundaries. This complexity can make the recoiling process more challenging as it may affect the material's mechanical properties and response to deformation. Lastly, the surface finish of high-strength steel coils is critical for many applications. Recoiling can introduce surface defects, such as scratches or marks, which may affect the functionality or appearance of the final product. Therefore, maintaining a high-quality surface finish during the recoiling process is a significant challenge. In summary, the challenges in coil recoiling for high-strength steel include the increased stress on recoiling equipment, lower ductility, shape memory effect, complex microstructure, and the need for a high-quality surface finish. Overcoming these challenges requires specialized equipment, precise control, and careful handling to ensure the integrity and quality of the recoiled high-strength steel coils.

- Q:How are steel coils used in the production of pipes?

- Steel coils are used in the production of pipes by being uncoiled and then passed through a series of forming and welding processes. The coils are flattened and shaped into the desired pipe size and then welded together to create a continuous length of pipe.

- Q:How are steel coils used in the production of industrial tanks?

- Steel coils are used in the production of industrial tanks as they are rolled into cylindrical shapes and welded together to form the tank's body. The coils provide a durable and strong structure, capable of withstanding high pressure and temperature conditions. Additionally, the steel coils can be customized to meet specific size and shape requirements, allowing for efficient and cost-effective tank production.

- Q:I have a Charles Daly shotgun and I'm trying to find out if it is ok to shoot steel out of. The side engravings say: Charles Daly 20 GA 3 and the other side says : KBI-HBG, PA made in TurkeyOn their website it says that the barrel on the Charles Daly 300 Field is able to shoot steel but I don't see anywhere that this is a 300 model.Im also not sure if the choke is able to shoot steel. It has no engravings on it. How can I tell if this choke will work? It is the original choke that came with the gun?

- I do not know that gun. I have the over/unders. A little checking. Now checking the specs it does describe the barrel steel, and that it is threaded to standard Rem Choke size threads. So before you shoot steel if you do not know what choke you have go to any gunshop and ask them to just stick their choke gauge in the choke. On the choke itself it should say what choke it is. For steel shot you should use one choke size LARGER then the way you want the gun to pattern. ie. A modified choke will shoot a full choke pattern. An Improved cylinder choke a modified pattern and so on. DO NOT use a full choke. the full choke is too tight, and steel shot does NOT deform like lead does. The first indication of a problem would be a bulge in the barrel out near the muzzle end. Run your hand down and feel it. The barrel steel is fine though just use or get the correct choke tube, AND what I said is if you so not have anything BUT a full choke buy a Rem Choke the size you want. Even Walldog sells Rem Chokes.

- Q:What are the common coil diameter and weight combinations available for steel coils?

- The common coil diameter and weight combinations available for steel coils vary depending on the specific requirements and industry standards. However, there are some commonly used combinations that are widely available in the market. In terms of coil diameter, the most common sizes range from 24 inches (610 mm) to 72 inches (1829 mm). These diameters are typically used for various applications in industries such as automotive, construction, and manufacturing. Regarding coil weight, the range can vary significantly depending on the type and thickness of the steel being coiled. For hot-rolled coils, the weight typically ranges from 5 to 30 metric tons. Cold-rolled coils usually have weights between 2 to 20 metric tons. Coils with larger weights are commonly used for heavy-duty applications, while lighter coils are preferred for more delicate or precise applications. It is important to note that these are just general guidelines, and the actual coil diameter and weight combinations can be customized based on the specific needs of the customer. Different manufacturers and suppliers may offer a wide range of options to accommodate various industry requirements. Therefore, it's always advisable to consult with the specific supplier to determine the available coil diameter and weight combinations that best suit your specific application.

- Q:What are the common surface defects found in steel coils?

- Steel coils can have several surface defects commonly found. One prevalent defect is rust or corrosion, which happens when moisture contacts the steel surface and causes oxidation and rust formation. Another defect is scratches or abrasions, occurring during coil handling or transportation. These can vary from small surface scratches to deeper gouges that affect the steel's structural integrity. Surface roughness or unevenness is also possible due to improper rolling or cooling processes during manufacturing, resulting in inconsistent surface texture that affects appearance and performance. Scale is another defect, forming an oxide layer during manufacturing, giving the steel a rough and uneven look. Finally, oil or grease stains may occur during manufacturing or handling, impacting paint or coating adhesion. These common surface defects impact steel quality, appearance, and performance, often requiring cleaning, grinding, or recoating as remedial actions.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Widely Used Color Coated Steel Coil/Al-Zn Steel Coil/PPGI

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords