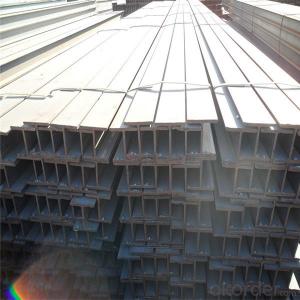

Wide Flange H-Steel Beams Steel with Full Size

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 120 m.t

- Supply Capability:

- 150000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Quick Detail

Place of Origin: | Tianjin, China (Mainland) | Grade: | Q235B | Technique: | High Frequency |

Application: | Building construction,Bridge construction etc. | Length: | 6.0meters,9meters,12meters | Standard: | ASTM |

Flange Width: | 100-750mm | Flange Thickness: | 3.0-10.0mm | Web Width: | 50-250mm |

Web Thickness: | 2.3-8.0mm | Brand Name: | Liye |

We can provide qualify goods,competitive price and speedy delivery.

Products Description

H Type Steel Size and Theoretical Weight | |||||

Size | Theoretical Weight | Size | Theoretical Weight | Size | Theoretical Weight |

|

|

|

|

|

|

(mm) | (kg/m) | (mm) | (kg/m) | (mm) | (kg/m) |

100*50*5*7 | 9.3 | 250*125*6*9 | 29 | 446*199*8*12 | 65.1 |

100*100*6*8 | 16.9 | 250*250*9*14 | 71.8 | 450*200*9*14 | 74.9 |

125*60*6*8 | 13.1 | 294*200*8*12 | 55.8 | 482*300*11*15 | 110.8 |

125*125*6.5*9 | 23.6 | 298*149*5.5*8 | 32 | 488*300*11*18 | 124.9 |

148*100*6*9 | 31.1 | 340*250*9*14 | 36.7 | 496*199*9*14 | 77.9 |

150*75*5*7 | 14 | 300*150*6.5*9 | 93 | 500*200*10*16 | 88.1 |

150*150*7*10 | 20.7 | 300*300*10*15 | 78.1 | 582*300*12*17 | 132.8 |

175*90*5*8 | 18 | 346*174*6*9 | 41.2 | 588*300*12*20 | 147 |

175*175*7.5*11 | 40.4 | 350*175*7*11 | 49.4 | 596*199*10*15 | 92.4 |

194*150*6*9 | 29.9 | 350*350*12*19 | 134.9 | 600*200*11*17 | 103.4 |

198*99*4.5*7 | 17.8 | 390*300*10*16 | 104.6 | 700*300*13*24 | 181.8 |

200*100*5.5*8 | 20.9 | 396*199*7*11 | 56.1 | 800*300*14*26 | 206.8 |

200*200*8*12 | 49.9 | 400*200*8*13 | 65.4 | 900*300*16*28 | 240.1 |

244*175*7*11 | 43.6 | 400*400*13*21 | 171.7 |

|

|

248*124*5*8 | 25.1 | 440*300*11*18 | 120.8 |

|

|

Length=6------12meters | |||||

Packaging & Delivery

Packaging Details: | Packed with waterproof paper and steel banding. |

Delivery Detail: | 15-25 |

FAQ

1. How can I get some samples?

We are honored to offer you samples. New clients are expected to pay for the courier cost. The samples are free for you.

2 Do you have any certificates?

Our products passed inspection of SGS, FDA, and CE Quality is priority! Every worker keeps the QC from the very beginning to the very end, Quality control department especially responsible for quality checking in each process.

3 Can your factory print or emboss my logo on the goods?

Yes, we can print or emboss the logo on the goods or their packing box.

4 What information should I let you know if I want to get a quotation?

1) The specification of products (length x width x thickness);

2) The temper and alloy.

3) The final product you will use to be made

4 It will be better if you can show us the pictures or design sketch. Samples will be best for clarifying. If not, we will recommend relevant products with details for reference.We usually produce goods based on customers

Samples or based on customers’ picture, logo, sizes etc.

- Q:How do steel H-beams perform in high winds?

- Steel H-beams are designed to have excellent strength and structural integrity, making them highly resistant to high winds. Their shape allows for efficient distribution of wind load, minimizing the risk of bending or structural failure. Consequently, steel H-beams perform exceptionally well in high winds, providing stability and ensuring the overall safety and durability of structures.

- Q:How do steel H-beams connect to other structural elements?

- Depending on the particular design and engineering needs of a project, Steel H-beams can be connected to other structural elements in various ways. One common approach involves the use of bolts or welds. When joining H-beams to other steel components like columns or beams, it is common to fasten them together using high-strength bolts. These bolts are inserted through pre-drilled holes in the flanges (the horizontal top and bottom sections) of the H-beam and then tightened with nuts. This establishes a secure and rigid connection between the H-beam and the other structural elements. Another method employed to connect steel H-beams to other structural elements is welding. In this case, the flanges of the H-beam are welded to the adjacent components, ensuring a robust and permanent connection. Welding is often favored when there is a need for high load-bearing capacity and structural integrity. Apart from bolts and welds, other connection methods such as connectors or brackets can also be utilized depending on the specific project requirements. These connectors or brackets are often designed to provide additional strength and stability to the connection between the H-beam and other structural elements. It is important to emphasize that the choice of connection method for steel H-beams is contingent upon various factors, including load-bearing capacity, structural design, and safety regulations. Structural engineers and designers meticulously consider these factors to ensure that the connection is strong, secure, and capable of withstanding the forces and loads imposed on the structure.

- Q:What are the different welding techniques used for steel H-beams?

- There are several welding techniques commonly used for steel H-beams. These techniques include: 1. Arc Welding: This is the most common welding technique used for steel H-beams. It involves the use of an electric arc between an electrode and the base metal to create the weld. Arc welding can be further divided into several sub-categories, such as shielded metal arc welding (SMAW), gas metal arc welding (GMAW), and flux-cored arc welding (FCAW). Each of these sub-categories has its own advantages and disadvantages, and the choice of technique depends on factors such as the thickness of the steel and the desired weld quality. 2. Gas Tungsten Arc Welding (GTAW): Also known as TIG (tungsten inert gas) welding, this technique uses a non-consumable tungsten electrode to create the weld. A separate filler metal is usually added to the weld pool manually. GTAW is known for its high-quality welds and is often used for applications that require precision and aesthetic appeal. 3. Submerged Arc Welding (SAW): This technique involves the use of a continuously fed wire electrode and a granular flux that covers the weld area. The arc is maintained below a layer of flux, which protects the weld from atmospheric contamination. SAW is commonly used for welding thick steel sections and is known for its high deposition rate and deep penetration. 4. Laser Beam Welding (LBW): This technique uses a highly focused laser beam to create the weld. LBW is known for its high precision and narrow heat-affected zone, making it suitable for welding thin steel H-beams. However, it is a relatively expensive technique and requires specialized equipment. The choice of welding technique for steel H-beams depends on various factors such as the thickness of the steel, the desired weld quality, production volume, and available equipment. Each technique has its own advantages and limitations, and it is important to select the most appropriate technique based on the specific requirements of the project.

- Q:Can steel H-beams be used in outdoor applications?

- Yes, steel H-beams can be used in outdoor applications. Steel H-beams are known for their strength, durability, and resistance to environmental conditions, making them suitable for various outdoor projects. These beams are often used in the construction industry for applications such as bridges, retaining walls, and building structures. Additionally, they can withstand exposure to moisture, extreme temperatures, and other elements without significant deterioration or loss of structural integrity. Therefore, steel H-beams are a reliable choice for outdoor applications where strength and longevity are crucial.

- Q:Are there any environmental benefits to using Steel H-Beams?

- Yes, there are several environmental benefits to using Steel H-Beams. Firstly, steel is a highly durable and long-lasting material, which means that H-Beams made from steel have a longer lifespan compared to other materials. This reduces the need for frequent replacements and decreases the overall environmental impact. Additionally, steel is a highly recyclable material, and H-Beams can be easily recycled at the end of their life cycle, reducing the demand for new steel production and conserving natural resources. Moreover, steel H-Beams have a high strength-to-weight ratio, allowing for the construction of lighter and more efficient structures, which reduces the amount of material required and lowers energy consumption during transportation and construction. Overall, the use of steel H-Beams contributes to sustainable construction practices and helps mitigate environmental impact.

- Q:Can Steel H-Beams be used in data center or IT facility construction?

- Data center or IT facility construction can indeed utilize Steel H-Beams. These H-Beams are commonly employed in commercial construction projects owing to their structural strength and versatility. With exceptional load-bearing capabilities, they are an ideal choice for supporting heavy equipment and infrastructure in data centers and IT facilities. Furthermore, Steel H-Beams possess durability, fire resistance, and the ability to withstand extreme weather conditions, ensuring the safety and longevity of the facility. Their flexibility allows for effortless customization and expansion, which proves crucial in dynamic environments such as data centers. All in all, Steel H-Beams offer a dependable and efficient solution for constructing data centers or IT facilities.

- Q:Can steel H-beams be used for supporting railway structures?

- Yes, steel H-beams can be used for supporting railway structures. They are commonly employed in the construction of railway bridges, viaducts, and other elevated structures due to their strength, durability, and ability to withstand heavy loads.

- Q:Are steel H-beams suitable for overhead cranes?

- Yes, steel H-beams are suitable for overhead cranes. H-beams are commonly used in the construction industry due to their high strength and durability. They provide excellent load-bearing capabilities, making them ideal for supporting heavy loads, such as those encountered in overhead crane applications. The structural design of H-beams allows for optimal weight distribution and efficient load transfer, ensuring the stability and safety of the crane system. Moreover, steel H-beams can be easily fabricated and welded, making them versatile and adaptable to various crane configurations and requirements. Overall, steel H-beams are a reliable and effective choice for overhead crane construction.

- Q:What are the common surface treatments available for steel H-beams?

- Steel H-beams have a variety of surface treatments available to enhance durability, appearance, and corrosion resistance. Some common treatments include: 1. Hot-dip galvanizing: Immersing the beams in molten zinc forms a protective coating, providing excellent corrosion resistance for outdoor or high-moisture environments. 2. Powder coating: A dry powder is applied to the beams, then heated and fused onto the metal, creating a durable and attractive finish that resists chipping, scratching, and fading. 3. Epoxy coating: This treatment adds a protective layer that resists corrosion, chemicals, and abrasion, making it suitable for industrial settings with harsh substances. 4. Painting: A popular treatment for steel H-beams, painting offers aesthetic appeal and corrosion protection. Beams are primed and coated with high-quality, weather and UV-resistant paint. 5. Shot blasting: Small metallic or abrasive particles are propelled at high speeds onto the beams' surface, removing rust, mill scale, and impurities, leaving a clean and roughened surface for further treatment. Choosing the appropriate surface treatment for steel H-beams depends on specific requirements, including application, environmental conditions, and aesthetic preferences. Factors like cost, durability, maintenance, and expected lifespan should be considered when selecting the most suitable treatment.

- Q:What are the different types of steel H-beams available?

- There are several different types of steel H-beams available, including standard H-beams, wide flange beams, and lightweight beams. Standard H-beams have a wider flange and are commonly used in construction and structural applications. Wide flange beams have a wider flange and are typically used for larger structural projects. Lightweight beams are designed to be lighter in weight, making them suitable for applications where weight is a concern, such as in automotive or aerospace industries.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Wide Flange H-Steel Beams Steel with Full Size

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 120 m.t

- Supply Capability:

- 150000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords