White Green Blue Food Grade PU Conveyor Belt for Biscuit Factory

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

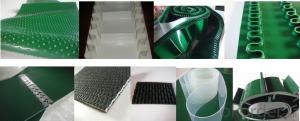

White Green Blue Food Grade PU Conveyor Belt for Biscuit Factory

PU Conveyor Belt

Colors: red, yellow, green, blue, gray, white, black, blue, green, transparent (in general we have)

Thickness: PVC (1~7mm) PU (0.8~4mm)

Appearance: flat surface, diamond pattern, lawn pattern, golf pattern etc.

Advantages: PVC: economical and practical, technology is mature.

PU: applicable to the food industry, abrasion resistant and corrosion.

Subsequent machining technology: it can add baffle, skirt, sponge, guide bar.

ADVANTAGES:

Low operating noise and costs, reduced maintenance, excellent durability.

Largely impervious to oils, greases and many chemicals.

Special types give excellent grip on inclination.

Abrasion resistant - rugged, high strength - low stretch characteristic.

Light and thin, better strength / weight ratio - energy saving.

Superb tracking over great length - longitudinally flexible and laterally stiff.

Just contact us freely if you need any PVC/PU conveyor belt,thank you!

- Q:Do olive nets affect the growth of olive trees?

- Yes, olive nets can affect the growth of olive trees. These nets are commonly used to protect olives from birds and other pests, but they can also impact the tree's growth by reducing sunlight penetration and air circulation. This can potentially result in reduced photosynthesis, nutrient uptake, and overall growth of the olive tree. However, if the nets are properly managed and allow for sufficient light and air flow, their impact on tree growth can be minimized.

- Q:Do olive nets affect the yield of the olive tree?

- Yes, olive nets can affect the yield of the olive tree. Olive nets are used to prevent the loss of olives due to wind or other factors. By protecting the olives from falling, olive nets can increase the overall yield of the olive tree. Additionally, these nets also protect the olives from damage caused by birds and other animals, further enhancing the yield.

- Q:How do olive nets affect the production of olive tree sap?

- Olive nets play a vital role in the production of olive tree sap. By covering the olive trees, these nets prevent the olives from falling on the ground, ensuring that the sap remains intact. This helps in increasing the overall sap production as it minimizes the loss of olives due to wind, birds, or other factors. Additionally, the nets also provide shade to the olive trees, reducing water evaporation and creating a favorable environment for sap production.

- Q:How does an olive net help prevent damage to the olives during harvesting?

- An olive net helps prevent damage to the olives during harvesting by providing a protective barrier that catches falling olives, preventing them from hitting the ground and getting bruised or damaged. This netting is spread out beneath the olive trees, allowing the olives to fall onto it instead of directly onto the ground. This gentle landing ensures that the olives remain intact and minimizes the risk of spoilage or contamination during the harvesting process.

- Q:Do olive nets prevent olives from getting sunburned?

- Yes, olive nets are effective in preventing olives from getting sunburned.

- Q:What are the requirements of laser marking for plastic products?

- Compared with other materials, plastics have the following characteristics: light weight, excellent chemical stability, excellent electrical insulation performance, wide mechanical strength distribution and higher specific strength. Based on the above characteristics, become the most commonly used plastic packaging materials, plastic products trademark, barcode and number for identification mark printing, usually by labeling, packaging and other processing methods of hot stamping contraction, or directly at the surface of the plastic mechanical processing, such as printing, engraving, punching and pressing

- Q:Are olive nets environmentally friendly?

- Yes, olive nets can be considered environmentally friendly. By using nets to harvest olives, farmers reduce the need for machinery and manual labor, which can have a negative impact on the environment. Additionally, olive nets help prevent olives from falling to the ground and getting damaged, reducing waste and improving overall productivity. However, it is important to ensure that the nets are properly installed and maintained to minimize any potential negative effects on local wildlife or ecosystems.

- Q:Are there any specific maintenance requirements for olive nets?

- Yes, olive nets require regular maintenance to ensure their effectiveness. Some specific maintenance requirements for olive nets include regular cleaning to remove debris and leaves, inspecting for any tears or holes that may compromise their functionality, and storing them properly when not in use to prevent damage. Additionally, it is important to check the tension of the nets periodically and adjust as necessary to ensure a secure fit around the olive trees.

- Q:How do olive nets prevent olives from getting damaged during rain or hailstorms?

- Olive nets prevent olives from getting damaged during rain or hailstorms by providing a protective barrier between the olives and the falling precipitation. The nets act as a shield, intercepting the rain or hail and preventing it from directly hitting the olives. This helps to minimize the impact and potential damage caused by the force of the falling water or ice, preserving the quality and integrity of the olives.

- Q:Are there any specific guidelines for using olive nets on dwarf or small-sized olive trees?

- Yes, there are specific guidelines for using olive nets on dwarf or small-sized olive trees. It is important to choose a net that is appropriately sized to cover the entire tree and secure it tightly to prevent any gaps. The net should be placed over the tree before the olives start ripening to protect them from birds and pests. It is advisable to periodically check the netting for any tears or damage and repair or replace it if needed. Additionally, the net should be removed after the harvest to allow for proper tree maintenance and prevent any potential damage.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

White Green Blue Food Grade PU Conveyor Belt for Biscuit Factory

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords