White Fused Alumina For Refractory Material

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t

- Supply Capability:

- 5000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

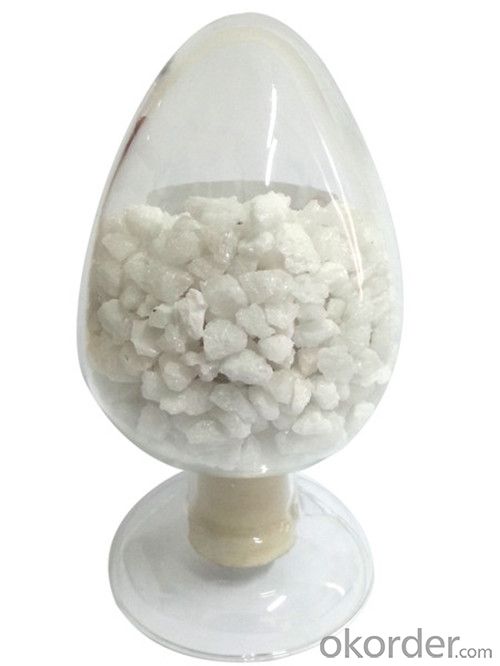

White Fused Alumina For Refractory Material

Specifications

White Corundum/WFA for Lapping and Polishing

1 Professional manufacturer

2 High purity

3 Good hardness and toughness

Product Description

White corundum/WFA is made from the high quality aluminum oxide powder by melting above 2,000°c in the electric arc furance and cooling.

Physical Index

| True Density | ≥3.96g/cm3 |

| Micro Hardness | HV2000-2200 |

| Mosh Hardness | 9 |

| Refractoriness | ≥1850°c |

| Melting Point | 2250°c |

Chemical Index

| Application | Specification | Chemical Composion(%) | |

| Al2O3 | Na2O | ||

| Abrasives | F12#-80# | 99.4min | 0.4max |

| 90#-150# | 99.3min | 0.4max | |

| 180#-240# | 98.2min | 0.4max | |

| 1#-63# | 99.3min | 0.4max | |

| Refractory | 180#-0 200#-0 320#-0

| 99.3min | 0.4max |

| Powder | 0-1mm 1-3mm 3-5mm 5-8mm 8-12mm | 99min | 0.4max |

Size Available

1 Abrasives F8-F1500, P12-P220, JIS240-JIS3000

2 Refractoy 0-1mm, 1-3mm, 3-5mm, 200mesh, 325mesh

3 Other specifal specification could be supplied as required

Main Applications

1 Coated and bonded abrasive tools

2 Lapping and polishing processe

3 Precision casting

4 Refractory material

- Q:Can the teflon material resist fire?

- It is belonged to the fire retardant materials. By UL-V0 grade

- Q:Which industry does refractory belong to?

- It belongs to inorganic refractory: Ceramic refractory bricks (used in steel-making furnaces) There is also organic polymer in heavy industry: Halogen-containing and halogen-free It belongs to construction industry.

- Q:what materials can make external wall fireproofing paint have the fireproofing effect

- Fire retardant coatings are generally used for fireproofing and fire?retardant of steel structure buildings, large stadiums, railway stations, thermal power station, nuclear power plants, urban tunnels, large-scale industrial plants, warehouses, flammable material surface. Improve the refractory time of buildings and combustible materials.

- Q:Does anyone know the refractory temperature of fire-resistant glass?

- Ordinary glass will burst under sharp temperature difference of about 70-120 degrees and toughened glass of 200 degrees. It is not yet clear for the bursting temperature differences of the refractory glass. If the overall glass is heated evenly, it will have no significant change below 600 degrees, and it will deform with the increase of temperature until melting. The fire-resistant time of the glass you said is the time to heat the glass into the extreme temperature differences it can endure, which should not be more than 10 minutes

- Q:which kind of refractory is commonly used in the industry

- Therefore it is known as special fire-resistant materials, such as yttria, high alumina raw material (sometimes neutral), olivine,which is used for alkalinity furnace, dolomite, and we roughly divided into several categories, beryllia, cerium oxide, these materials have a strong alkaline slag resistance, thorium oxide, lime, serpentine, which is picked from these refractory raw materials. the raw materials of basic refractory materials are mainly magnesia clay and titanium oxide, but because not many sources of raw materials, it can not be widely applied in the refractory industry, and we can analyze which kind of materal is processed by the pulverizer. There are many kinds of refractory materials, rotary?kiln can only be used in particular circumstances. These materials have a variety of slag resistance at different degrees. the main material of special refractories is zirconium oxide. the refractory clay is the most basic and most widely used raw material in the refractory industry.

- Q:What are the uses of refractory materials of glass furnace?

- crown--high-purity silica bricks; wall--melting end 41# fused zirconia corundum bricks with no shrinkages(41% of zirconium, similarly hereinafter), cooling end 33# fused zirconia corundum bricks with no shrinkages; bottom--33# fused zirconia corundum bricks(with shrinkages); breastwork--33# fused zirconia corundum bricks(with shrinkages); port--33# fused zirconia corundum bricks(with shrinkages); regenerator chamber--the upper part is for magnesite-chrome bricks, the bottom part is for high-duty fireclay bricks; checker--the upper part is for high purity magnesia bricks, and the bottom part is for magnesite-chrome bricks; flue--clay bricks.

- Q:Introduction to refractory material

- The best way to learn is on-site contact. If for produing purpose, it is better to ask teh leader of a plant. If for application, go to steel mill (cement plant, glassworks, etc.) to learn and look up information. Theory alone is of no help.

- Q:What's the A grade fireproofing material?

- A grade fireproofing material: 1. fire-proof plate; 2. fireproof wooden door; 3. fireproof wooden window frame; 4. fire resisting shutter; 5. fireproof and mothproof wood; 6. fireproof glove compartment; 8. fire?retardant?coating; 9. fire-proof?sealing?material.

- Q:What is the best refractory company?

- Chinese brick trading network, is the most authoritative third party service platform, brought together more than 3000 refractory enterprises, working day experts online to answer, to analyze and evaluate the refractory industry, at the same time, cooperation with some refractories Association, I hope to help you!

- Q:How to divided the grade of external wall thermal insulation materials?

- 1, According to China's national standard GB8624-97, combustion performance of building materials will be divided into the following grade level A: Incombustible building material: It is a kind of material that almost does not occur burning. Level B1: Nonflammable building material: Non-flame material has good flame resistance. It is difficult to fire under the condition of open fire in the air or high temperature, and it is not easy to quickly spread, and when the combustion?source is removed, the combustion will stop immediately. Level B2: Combustible?building?materials: Flame material has a good flame resistance. In case of fire in the air or at high temperature, it will immediately burst into flames, and easily lead to the spread of fire, such as wooden column, timber roof truss, timber beam and wooden stairs. Level B3: Combustible?building?materials: It has no any flame resisting effects, and is easy to burn, so the fire risk is high. 2, The external wall thermal insulation materials is divided by fire rating 1) level A combustion performance thermal insulation material Rock wool, glass wool, foam glass, foamed ceramics, foam cement, hole-closed perlite, etc. 2. combustion performance is level B1 insulation materials: Extruded polystyrene board (XPS) after special treatment / Special treatment of polyurethane (PU), phenolic aldehyde and gelatine powder polyphenyl granule 3, combustion performance is level B2 insulation material: Molded polystyrene board (EPS), extruded polystyrene board (XPS), polyurethane (PU), polyethylene (PE), etc. I hope my amswers are helpful to you

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

White Fused Alumina For Refractory Material

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t

- Supply Capability:

- 5000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords