Wheel Loader - Cl936 Series Chinese Wheel Loader

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description Wheel Loader - Cl936 Series Chinese Wheel Loader

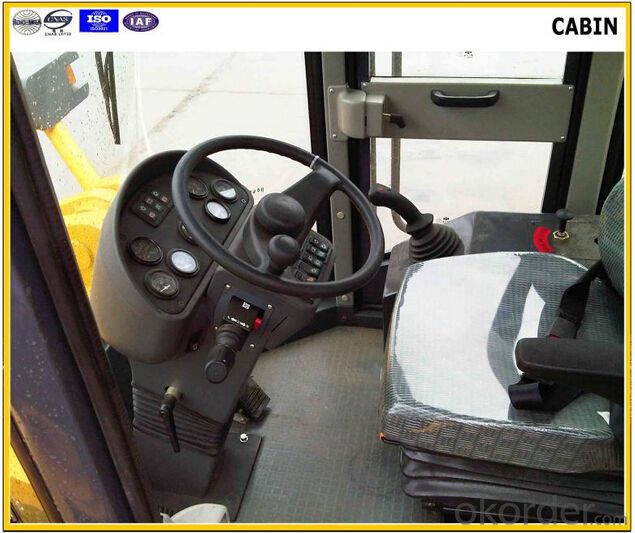

Compact Integrated Transmission

One shifting lever is for speed and direction

Fuel Economy world class engine, stage-II

Joystick Pilot control

Large module gear axle (Full sealed, wet brake -optional)

Super longer boom for rice mill.

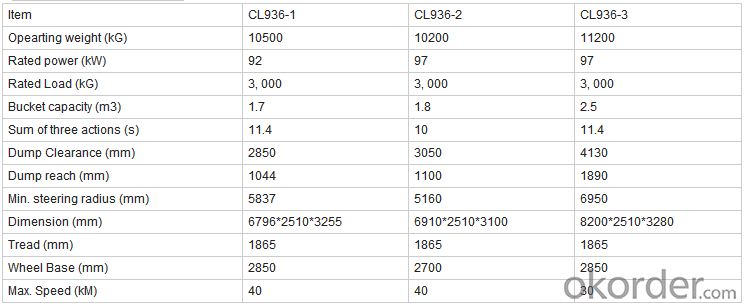

Specification Wheel Loader - Cl936 Series Chinese Wheel Loader

Model NO.:CL956 Series

Drive Type:Internal Combustion Drive

Bucket Capacity:>1.5m³

Transmission:Mechanical Transmission

Type:Loader

Size:Large-Scale

Condition:New

Certification:ISO9001: 2000, Rops,TUV,Ghost

Export Markets:North America, South America, Eastern Europe, Southeast Asia, Africa, Oceania, Mid East, Eastern Asia

FAQ Wheel Loader - Cl936 Series Chinese Wheel Loader:

1.How about the shipment?

1. The loader machine load one 40HQ container.

2. The loader disassemble into 3 parts, major machine, bucket and cabin.

3. Before shipment, we have done the rust-proof and antiseptic treatment.

2. What about your service?

We have our factory, we can meet customers needs as soon as possible.

We have first rate professional technology and provide good after-sales service.

3. What Can we Do For You?

1. During the period of 12 months or 2000 working hours warranty, Chaogong factory are responsible for maintenance and replacement of spare parts.

2. We attend the machinery exhibition in your country and please contact us when we are with you at that time and solve the problem you have.

3. For the sole agents, we will go with senior engineer to your country and offer the technical service.

- Q:Hi. I am getting a few baby bearded dragons in a couple months. I was wondering what size terrarium I should put them in. I am getting 1 male and 2 females. I was also wondering if I should put some burrows in with some burrow maker thing I got. I have 10 pounds of it and it is made of clay. Also, will they get along with Leopard geckos? I really want to put in a pair of leopard geckos, and will they like the burrows too? I want both the bearded dragons and the geckos to breed and I will make 2 rooms in each burrow for them. I am also adding a heating pad to help incubate the eggs and to keep the reptiles warm. And a heating rock or two is going to be placed in there. Any help and advice would be greatly appreciated!

- First, you cannot keep the beardies all together. They prefer to be alone and you will run into many problems by keeping them together. You will have nipped tails, missing toes, possibly missing feet, even dead dragons. They may appear to be getting along, but one, possibly 2 will slowly fade away and by the time you notice one not doing so well, it will take a lot of work to get it back into shape. Also, when they are a litle older, they will begin to breed and the females will not be old enough, leading to a whole new set of problems (mbd, egg binding, etc) I am not sure about the burrow stuff, as I have never heard of it. Dragons will eat the geckos. Once you have gotten them to breed, a heat pad will not incubate the eggs. The eggs will need to be kept at certain temps and humidity that will need to be monitored. Plus, a hatchling of either species is just seen as food for the larger ones. Heat rocks are very, very dangerous. They do not heat evenly and are known to have heat spikes that will cause your lizards to get burnt. I suggest you do a lot of reading and researching on the care requirements of both species and rethink you decision to try to breed until you have everything set up properly. It takes a lot of time, space, and money to breed dragons. Leos are a little easier, but still require more than just throwing a pair together.

- Q:What kind of excavator is trong?

- From the development of engineering machinery in recent years, the development of excavator is relatively fast, excavator has become one of the most important construction machinery in engineering construction. The three most important parameters of excavator are operation weight (quality), engine power and bucket bucket capacity.

- Q:Where is the throttle motor for the excavator?

- The throttle motor position of each company may be different. There's a stupid way to help you. You can find it along the throttle line of the engine

- Q:Where can I find a really good deal online for CAT Excavator

- The more you look the more you will find, if you have the time you can find a good deal.

- Q:I took a traineeship in hospitality very hastily and I have realised I HATE it, the 5.30am starts (I don't mind getting up at 5.00am but not starting work then I don't like) I was looking at looking for an Electrician Apprenticeship or getting in to Heavy Vehicle Operating (Bobcats, Front-end loaders, Excavators etc.) but other than doing the TAFE courses I'm not sure how I would go about getting to it as a job.I'm after PROS and CONS from people who know what they are talking aboutRegards

- If you don't like it your not gonna last, do something you like to do. If you want to work on Heavy Vehicles talk to you counciler they can usually point you in the right direction. I can give you pros and cons, but my oppinion might be differnt from your or the next person. Hope this helps you out

- Q:How can i get excavater operater job in australia let me know the company name?

- The occupation of Excavator Operator is not eligible for any Australian work visa. It is not listed on the CSOL and it is regarded as unskilled or low skilled work so is not even eligible to an RSMS visa which is the only visa for which there is no list of occupations.

- Q:Ok, I'm going to repost this question, because it's NOT Bob the Builder! Since when was Bob the Builder in the early 90s??? lolHere's my question: Ok, this is driving me crazy. I can't think of a show I used to watch as a kid. I'm pretty sure it was on PBS kids (that's really all I used to watch), but I looked at a list of old programs and I can't find it! It was a show where there was this man (possibly a construction worker) and he was friends with a living excavator-like machine. I can't remember exactly if the machine talked, but it was definitely quot;alivequot;. She had a name too, I think it started with an quot;Mquot;? I just can't think of it! I used to watch this show in the early 90s. Any ideas of what this show is?Thank you!

- There was an old book called Mike Mulligan and his Steam Shovel, and the steam shovel's name was Mary Ann (written by Virginia Lee Burton), and I think I remember hearing tell of a show based on them. Could this be what you're looking for?

- Q:What engine Hitachi excavator?

- Hello!Hitachi excavator engineNow is a multi Isuzu enginePlease accept, thank you!

- Q:Homeowner hires excavator to clear earth out of his basement. Excavator encounters stone, says it will cost more. Takes WAY more time to complete, then sues the homeowner when he doesn't pay.I remember the judge found in favor for the excavator, and I think it was on a quantum meruit theory, but this case didn't pop up in the section used to illustrate quantum meruit/quantum valebat. May have been policing the bargain. Stone was not part of the original contract. May have been around the time of the famous case involving the selling of a cow which turned out to be a milking cow unknown to either party.Also, what part of the UCC would this be covered under? thanks

- It deals with revisions of contractual duty. The case is Brian Constr. Dev. Co. v. Brighenti. I may be wrong, but I don't think this case is covered under the UCC. The UCC deals with the sale of goods, not services.

- Q:When they mark the underground cables and pipes in the street, what does USA mean?

- Underground Service Alert (USA) is a free service for homeowners, excavators and professional contractors who are digging, blasting, trenching, drilling, grading, or excavating.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Wheel Loader - Cl936 Series Chinese Wheel Loader

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords