Tinplate with Prime Quality for Tin Containers

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

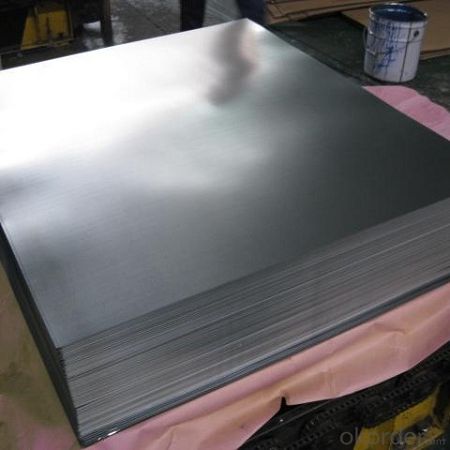

Tinplate with Prime Quality for Tin Containers

Tinplate Specification

Tinplate, as the name suggests, is coated on both sides with pure tin at various coating weights between 1 and 12 grams per square meter. It has extremely beautiful metalllic luster as well as excellent properties in corrosion resistance, solder ability, and weld ability.

Tinplate Applications

Tinplate is widely used for making all types of containers, electrical machinery parts and many other products.

Chemicals and painting cans

Dry food cans, such as fancy cans, biscuit cans, milk powder cans, tea cans.

Tinplate Pictures

Tinplate Features

Steel Type: MR, SPCC

Temper(BA& CA): T1- T5, DR8- DR10

Coating: 1.1- 8.4g/m^2

Tickness: 0.15- 0.,50mm

Width: 600-1010mm

I.D: 508mm

Coil weight: 3- 10mt

Passivation: 311

Oiling: DOS

Surface finish: Bright, Stone

Quantity for 20 Feet FCL: 20- 25MT

Package: Seaworthy Export Standard Wooden Pallet

Application

Tinplate is widely used for making all types of containers, electrical machinery parts and many other products

Chemicals and painting cans

Dry food ccans, such as fancy cans, biscuit cans, milk powder cans, tea cans.

Liquid food cans, such as edible oil cans, beverage cans, Tomato paste cans

Sea food cans

Crown corks, easy open ends

Electrical machinery parts

Bakeware and household kitchen parts

Production Standard

GB/T 2520-2000

JIS G3303-2002

DIN EN 10202-2001

ASTM A623M-2002

ISO 11949-1995

- Q:What are the health and safety concerns associated with tinplate?

- Tinplate, a thin steel sheet coated with a layer of tin, can present some health and safety concerns. One primary concern is the potential for tin contamination in food or beverage products stored in tinplate cans. Prolonged exposure to high levels of tin can lead to health issues such as gastrointestinal problems, kidney damage, and even neurological disorders. Additionally, the manufacturing process of tinplate involves the use of chemicals and substances that may pose risks to workers, such as potential inhalation hazards or skin irritation. Proper handling, storage, and adherence to safety guidelines are crucial to minimize health and safety risks associated with tinplate.

- Q:Can tinplate packaging be used for electronic products?

- Yes, tinplate packaging can be used for electronic products. Tinplate is a durable and corrosion-resistant material that provides good protection for electronic devices. It can be used to make packaging boxes, cases, or containers to safeguard and store electronic products effectively.

- Q:What are the main factors affecting tinplate coil surface finish?

- The main factors affecting tinplate coil surface finish are the quality of the tin coating, the cleanliness of the substrate, the surface roughness of the steel base, and the processing conditions during manufacturing.

- Q:What are the different coating weights available for tinplate?

- The different coating weights available for tinplate typically range from 1.0 to 11.2 grams per square meter (g/m²), with common options including 2.8, 5.6, and 8.4 g/m².

- Q:How does tinplate contribute to the preservation of aerosol products?

- Tinplate contributes to the preservation of aerosol products through its excellent barrier properties. The tin coating on the steel provides a protective layer that prevents the metal from reacting with the contents of the aerosol can, thus preserving the quality and efficacy of the product. Additionally, tinplate cans offer resistance to corrosion and provide a hermetic seal, preventing any external elements from contaminating the aerosol contents.

- Q:Can tinplate be used for musical instruments?

- Yes, tinplate can be used for musical instruments. It is often used in the construction of various percussion instruments such as cymbals and tambourines due to its durability, resonance, and ability to produce unique sound qualities.

- Q:How does tinplate packaging contribute to product protection against UV rays?

- Tinplate packaging helps to protect products against UV rays by acting as a barrier, preventing the penetration of harmful ultraviolet light. The reflective properties of tinplate also minimize the absorption of UV radiation, further safeguarding the product from potential damage caused by exposure to sunlight.

- Q:How does tinplate contribute to the performance of ammunition?

- Tinplate contributes to the performance of ammunition in several ways. Firstly, tinplate acts as a barrier between the ammunition's metallic components and the environment, preventing corrosion and ensuring the ammunition remains functional over time. Additionally, the smooth surface of tinplate reduces friction and enhances the flow of ammunition through firearms, improving the overall reliability and performance of the weapon. Furthermore, tinplate's strength and durability provide necessary protection to the ammunition during handling, transportation, and storage, ensuring it remains intact and ready for use when needed.

- Q:What are the welding methods used for tinplate?

- The welding methods commonly used for tinplate are spot welding, seam welding, and resistance welding. These methods ensure a strong and durable bond between tinplate sheets, making them suitable for various applications such as food cans and packaging materials.

- Q:Can tinplate be used for pharmaceutical packaging?

- Yes, tinplate can be used for pharmaceutical packaging. Tinplate is a type of steel coated with a thin layer of tin, which provides excellent protection against corrosion and ensures the integrity and safety of pharmaceutical products. It is commonly used for the production of cans, containers, and closures, making it a suitable choice for pharmaceutical packaging due to its durability, resistance to light and moisture, and ability to maintain product quality and safety.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Tinplate with Prime Quality for Tin Containers

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords