Tinplate for making cans with competitive price

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

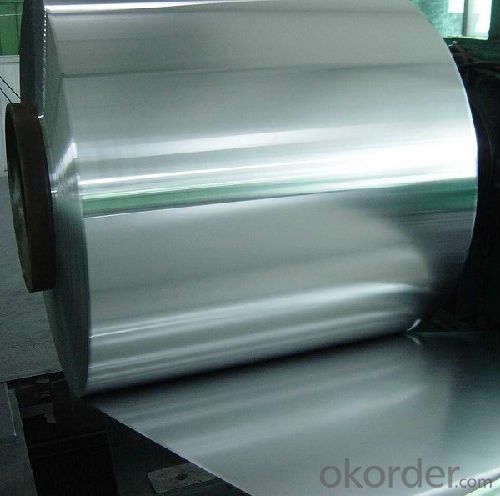

Tinplate for making cans with competitive price

1.Structure of Description

Electrolytic Tinplate Sheets is one of the metal packing materials, which is widely used for making painting cans ,chemical package cans , electrical cable ,battery and metal printing etc. For caps, there are some customers also need TFS, if you have some demand for TFS,also can contact with us.

2. Main Features

Steady and high quality

Fast shipment

Good experience for export work

For the surface, Plate uniform in thickness,uniform and smooth tin coating, without flaws,rusts,scratch,wave,nick of tin coating etc.

Specifications

| Type | MR, SPCC |

| Temper(BA&CA) | T1-T5, DR8-DR10 |

| Coating | 1.1-8.4g/m^2 |

| Thickness& Tolerance | 0.15-0.5mm(tolerance +/-0.01mm) |

| Width& Tolerance | 600-1010mm(tolerance +2/-0mm) |

| I.D | 508mm |

| Coil weight | 3-10MT |

| Passivation | 311 |

| Oiling | DOS |

| Surface finish | Bright, stone |

| Package | Seaworthy Export Standard Wooden Pallet |

| Standard | ISO 11949 -1995, JIS G3303,ASTM A623, BS EN 10202 |

| Special specifications are available on customers' requirements | |

FAQ

1. What is your tinplate used for?

Tinplate is widely used for making all types of containers, electrical machinery parts and many other products.

- Chemicals and painting cans

- Dry food cans, such as fancy cans, biscuit cans, milk powder cans, tea cans,

- Sea food cans

- Crown corks, easy open ends

- Electrical machinery parts

- Bakeware and household kitchen parts

2. What is your annual capacity?

Our annual capacity is 400,000MT

3. How many companies and factories in your group?

There are over 300 subordinate companies and factories in our group.

- Q:How is tinplate protected during transportation and storage?

- Tinplate is protected during transportation and storage through various measures such as applying protective coatings, using packaging materials like wooden crates or pallets, and ensuring proper handling and storage conditions to prevent damage from moisture, corrosion, and physical impact.

- Q:Can tinplate be used for electrical components?

- Yes, tinplate can be used for electrical components. Tinplate is a commonly used material in the electronics industry due to its excellent conductivity and corrosion resistance properties. It is often used for making connectors, terminals, and other electrical parts.

- Q:Can tinplate be used for packaging frozen foods?

- Yes, tinplate can be used for packaging frozen foods. Tinplate is a commonly used material for food packaging due to its durability, resistance to corrosion, and ability to maintain product freshness. It provides a reliable barrier against moisture and oxygen, making it suitable for preserving the quality of frozen foods.

- Q:What are the main differences between tinplate and tinplate laminates?

- The main differences between tinplate and tinplate laminates lie in their composition and functionality. Tinplate is a steel sheet coated with a thin layer of tin, providing excellent corrosion resistance and a shiny appearance. On the other hand, tinplate laminates consist of a layer of tinplate combined with other materials like paper, plastic, or film. These laminates offer enhanced properties such as improved barrier protection, flexibility, and customization options for specific packaging needs. Overall, tinplate laminates offer a wider range of applications and versatility compared to traditional tinplate.

- Q:How does tinplate perform in terms of light blocking properties?

- Tinplate is known to provide excellent light blocking properties due to its opaque and reflective nature, making it an effective choice for packaging materials to prevent light exposure and preserve the quality of light-sensitive products.

- Q:How does tinplate ensure the freshness of pet food?

- Tinplate ensures the freshness of pet food by providing a durable and airtight packaging solution. The tin coating on the steel sheet prevents any reaction between the metal and the pet food, keeping it safe from contamination. The hermetically sealed tinplate cans also protect the food from exposure to oxygen, light, and moisture, which can lead to spoilage. This ensures that the pet food remains fresh and maintains its quality for a longer shelf life.

- Q:Can tinplate packaging be used for medical products?

- Yes, tinplate packaging can be used for medical products. Tinplate is a durable and versatile material that provides excellent protection against moisture, light, and oxygen. It is commonly used for pharmaceuticals, medical devices, and sterile supplies. Tinplate packaging is known for its ability to maintain product integrity and extend shelf life, making it a suitable choice for medical products.

- Q:What are the main applications of tinplate in the energy industry?

- Tinplate finds various applications in the energy industry, primarily in the manufacturing of batteries and solar panels. It is commonly used as a protective coating for the metal components of batteries, preventing corrosion and extending their lifespan. Additionally, tinplate is used in the production of solar panels, where it acts as a reliable barrier against moisture and other environmental factors, ensuring the longevity and efficiency of the panels.

- Q:How does tinplate perform in terms of mechanical strength and durability?

- Tinplate is known for its excellent mechanical strength and durability. It is highly resistant to bending, denting, and breaking, making it ideal for various applications where strength is crucial. Additionally, tinplate is highly durable and can withstand harsh environmental conditions, including corrosion and rust. Overall, tinplate is a reliable and long-lasting material in terms of mechanical strength and durability.

- Q:Can tinplate be used for packaging medical devices?

- Yes, tinplate can be used for packaging medical devices. Tinplate is a strong and durable material that provides excellent protection and barrier properties to ensure the safety and integrity of medical devices. It is also resistant to corrosion and can be easily sterilized, making it suitable for packaging in the medical industry.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Tinplate for making cans with competitive price

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords