Tin Free Steel and Tinplate for Prime Quality and best Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 40900 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

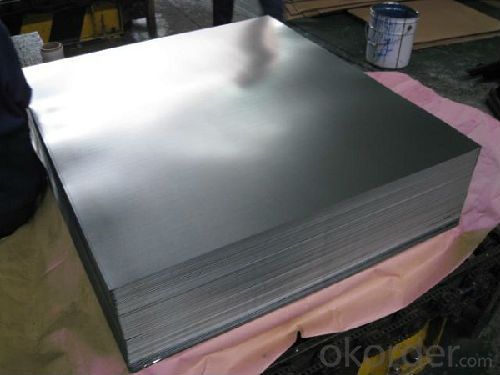

Prime Quality Tinplate Sheets Details

1.Structure of Description

Electrolytic Tinplate Sheets is one of the metal packing materials, which is widely used for making painting cans ,chemical package cans , electrical cable ,battery and metal printing etc. For caps, there are some customers also need TFS, if you have some demand for TFS,also can contact with us.

2. Main Features

Steady and high quality

Fast shipment

Good experience for export work

For the surface, Plate uniform in thickness,uniform and smooth tin coating, without flaws,rusts,scratch,wave,nick of tin coating etc.

Minumum Order Quantity: 25 MT Loading Port:China Main Port

Annual Capacity: 400,000MT Payment Terms:TT or LC

Product Specifications:

Prime Quality Tinplate Sheets Usage and Applications

Prime Quality Tinplate Sheets Specifications

Standard : GB2520-2000 ,JIS G3303

Steel type : SPCC

Coating : 2.8/2.8

Surface: Bright, Stone ,

Thickness:0.18

Width :600MM~1000MM

Temper : T1~T5

Package: tinplate wrapped completely with an inner cover of plastic or waterproof papers with vorners protected with metal angels.

Applications

Chemicals and painting cans

Dry food cans, such as fancy cans, biscuit cans, milk power cans, tea cans

Liquid food cans, such as edible oil cans, beverage cans, Tomato paste cans

Sea food cans

Crown corks, easy open ends(EOE)

Electrical machinery parts

Bakeware and household kitchen parts

FAQ

A. What is the package of tinplate? (Referred as below)

For sheets, thin plastic film + rust-proof paper + metallic cover + metallic angles+ steel band strips + fumigated wooden pallet.

For coil, thin plastic film + rust proof paper + metallic cover + steel band strips + fumigated wooden pallet

B. The surface of tinplate could you supply?

Stone finish, Bright finish, Matte finish, Silver finish

- Q:How is tinplate affected by exposure to chemicals?

- Tinplate is generally resistant to chemical exposure, making it a suitable material for packaging and storage of various products. However, certain aggressive chemicals or strong acids can corrode the tinplate coating over time, potentially compromising the integrity of the container or affecting the quality of the contents. It is important to consider the specific chemicals involved and their concentration when assessing the potential effects on tinplate.

- Q:How does tinplate perform in terms of impact resistance?

- Tinplate demonstrates good impact resistance due to its inherent strength and durability. It can withstand moderate impact without denting or deforming easily, making it suitable for various packaging and industrial applications.

- Q:Can tinplate be used for medical or pharmaceutical packaging?

- Yes, tinplate can be used for medical or pharmaceutical packaging. Tinplate is a durable and corrosion-resistant material that provides an excellent barrier against moisture, light, and oxygen, which is crucial for preserving the quality and integrity of medical or pharmaceutical products. Additionally, tinplate's ability to be sterilized makes it suitable for packaging items that require a high level of hygiene.

- Q:Can tinplate packaging be used for industrial products?

- Yes, tinplate packaging can be used for industrial products. Tinplate is a durable and corrosion-resistant material that provides excellent protection for various industrial goods. It is commonly used for packaging industrial chemicals, paints, lubricants, and other similar products. The robustness and versatility of tinplate make it suitable for handling and transporting these items efficiently and safely.

- Q:How is tinplate coated for pharmaceutical packaging?

- Tinplate for pharmaceutical packaging is typically coated using a process known as electrolytic tin coating. This involves immersing the tinplate in an electrolyte solution and passing an electric current through it. The electric current causes tin ions to be deposited onto the surface of the tinplate, creating a thin and uniform layer of tin coating. This coating provides a protective barrier against corrosion and ensures the safety and integrity of the pharmaceutical products packaged within.

- Q:Can tinplate be welded or soldered?

- Yes, tinplate can be welded or soldered.

- Q:How does tinplate perform in terms of gas barrier properties?

- Tinplate performs fairly well in terms of gas barrier properties. It provides a good barrier against oxygen and moisture, helping to preserve the quality and freshness of packaged goods. However, it may not be as effective as some other packaging materials, such as aluminum, in preventing the permeation of certain gases.

- Q:What are the main factors influencing the growth of the tinplate market?

- The main factors influencing the growth of the tinplate market include increasing demand for packaged food and beverages, the growth of the automotive industry, rising consumer awareness about sustainable packaging, and advancements in tinplate manufacturing technologies. Additionally, factors such as changing lifestyles, urbanization, and the need for lightweight and durable packaging solutions are also driving the growth of the tinplate market.

- Q:What are the main challenges in tinplate storage and transportation?

- The main challenges in tinplate storage and transportation include ensuring proper protection against rust and corrosion, maintaining temperature control to prevent damage to the tinplate, preventing stacking or handling errors that may result in dents or scratches, and ensuring efficient logistics to minimize delays and damage during transportation. Additionally, complying with safety regulations and maintaining adequate inventory management are also significant challenges in tinplate storage and transportation.

- Q:How does tinplate perform in terms of corrosion resistance compared to other materials?

- Tinplate generally has a good level of corrosion resistance compared to other materials, especially when it is properly coated with tin. The tin coating acts as a protective barrier, preventing direct contact between the base metal (usually steel) and the surrounding environment. This helps to minimize the impact of moisture, oxygen, and other corrosive elements on the tinplate surface. However, it is important to note that the level of corrosion resistance can vary depending on the thickness and quality of the tin coating, as well as the specific application and exposure conditions.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Tin Free Steel and Tinplate for Prime Quality and best Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 40900 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords