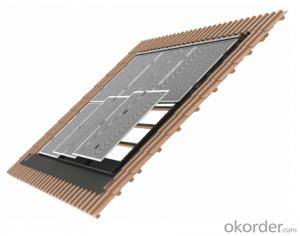

Tile-in Roof Solar Mounting System: VRTI1

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1500 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Tile-in Roof System VRTI1 own designed BIPV systems can be applied to different architectural needs, aiming to change the buildings into a cost-effective, efficient & environmental friendly energy generation plant.

• Designed for thin film module

roof installation

• Perfect fit-in: equal inclination

inbetween module upper

surface and tile upper surface

• 100% leak-proof

• With anti-skidding hook, air

flow panel

• Aesthetical appeal

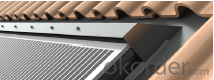

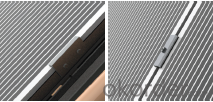

The upper waterproof panel will avoid the leakage between tiles and modules.

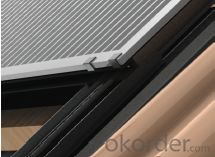

End clamp with drilling screws & middle clamp with bolt for the installation of module.

Both sides of module use rubber sealling strip for sealment, ensuring 100% waterproof.

Anti-skidding hook for easy installation.

Drilling screws used for fixation between rails & wood beam

FAQ

I..Will you focus on the safety of the goods during transportation?

Yes, Safety of the cargo is the primary element that we would consider on transportation.

II..How would guarantee the quality will meet the requirements of your clients?

Before shipment, we will have inspection for each batch of goods.

III..What certificates do you have?

IEC,UL,TUV,CSA,etc.

IV..Can you do OEM according to clients’ requirements?

Yes, we have our own brand while we can provide OEM service.

- Q:Can a solar mounting system be used in off-grid applications?

- Yes, a solar mounting system can be used in off-grid applications. In off-grid scenarios, where there is no access to the utility grid, solar mounting systems are essential for securing and optimizing solar panels to generate electricity from sunlight. These systems ensure proper orientation, angle, and stability of the panels, enabling efficient energy production even in remote or isolated locations.

- Q:Can a solar mounting system be installed on a multi-story building or skyscraper?

- Yes, a solar mounting system can be installed on a multi-story building or skyscraper. In fact, these tall structures provide ample rooftop space for solar panels, making them ideal candidates for solar energy generation. However, the installation process may require additional precautions and engineering expertise to ensure structural integrity and proper weight distribution.

- Q:Are there any specific requirements for row spacing when using a solar mounting system for solar farms?

- Yes, there are specific requirements for row spacing when using a solar mounting system for solar farms. The row spacing typically depends on various factors such as the tilt angle of the solar panels, the type of mounting system used, and local weather conditions. Generally, the row spacing is determined to ensure adequate sunlight exposure and prevent shading between rows, which can impact the overall energy production of the solar farm.

- Q:Can a solar mounting system be used in areas with limited access to power purchase agreements?

- Yes, a solar mounting system can still be used in areas with limited access to power purchase agreements. While power purchase agreements (PPAs) involve buying electricity from a third party, a solar mounting system can be used for self-consumption of generated solar power in such areas. This allows individuals or businesses to reduce their reliance on grid power and generate their own electricity, even without a PPA. Additionally, excess solar energy can be stored in batteries for later use, further enhancing energy independence in areas with limited access to power purchase agreements.

- Q:Can a solar mounting system be used on green roofs?

- Yes, a solar mounting system can be used on green roofs. In fact, many solar installations are now being integrated with green roofs to maximize energy efficiency and environmental benefits. Green roofs provide additional insulation and help regulate temperature, which can enhance the performance of solar panels. It is important to design and engineer the mounting system properly to ensure compatibility with the green roof structure.

- Q:Can a solar mounting system be used in areas with solar incentives for manufacturing facilities?

- Yes, a solar mounting system can definitely be used in areas with solar incentives for manufacturing facilities. In fact, utilizing a solar mounting system can be highly beneficial in such areas as it allows manufacturing facilities to harness solar energy effectively, reduce their reliance on traditional grid power, and take advantage of the financial incentives provided by the government or local authorities for adopting renewable energy sources.

- Q:Can a solar mounting system be used with solar-powered water pumps?

- Yes, a solar mounting system can be used with solar-powered water pumps. A solar mounting system provides a stable structure to hold solar panels, which generate electricity from sunlight. This electricity can then be used to power solar-powered water pumps, allowing for an environmentally friendly and sustainable way to pump water.

- Q:How is a solar mounting system installed?

- A solar mounting system is typically installed by first preparing the area where the panels will be installed, such as clearing any obstructions and ensuring the surface is stable. Then, the mounting structure is assembled, which includes attaching the rails or brackets onto the roof or ground. Next, the solar panels are mounted onto the rails or brackets using clamps or brackets. Finally, the electrical connections are made, including connecting the panels to the inverter and the inverter to the electrical system.

- Q:Can solar mounting systems be installed on flat roofs?

- Yes, solar mounting systems can be installed on flat roofs. There are specific mounting systems designed for flat roofs that provide proper tilt and orientation for optimal solar panel performance. These systems use ballast or weighted frames to securely anchor the panels without penetrating the roof's surface.

- Q:Are there any specific requirements for foundation when using a solar mounting system on flat ground?

- Yes, there are specific requirements for the foundation when using a solar mounting system on flat ground. The foundation must be strong enough to support the weight of the solar panels and mounting system, and it should be able to withstand environmental factors such as wind, rain, and snow. Additionally, the foundation should be level and properly aligned to ensure optimal performance and longevity of the solar system.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Tile-in Roof Solar Mounting System: VRTI1

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1500 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords