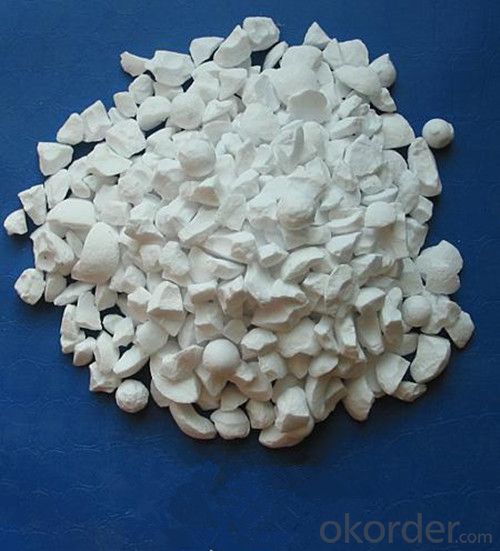

Tabular Alumina For Refractory With Nice Delivery Time

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t

- Supply Capability:

- 5000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Tabular Alumina For Refractory

Specifications

Tabular Alumina is high purity alumina processed by CE Minerals.Used as refractory,abrasives,polishing,grinding,ceramics.

Typical Size

48mesh 100mesh 200mesh -35mesh 0.1-0.3mm 0-1mm 1-3mm 3-5mm

Guarantee Value

Item | Unit | Index | Typical | |

Chemical composition | Al2O3 | % | 99.00min | 99.5 |

SiO2 | % | 0.20max | 0.09 | |

Fe2O3 | % | 0.10max | 0.07 | |

Na2O | % | 0.30max | 0.20 | |

CaO | % | 0.1max | 0.03 | |

MgO | % | 0.1max | 0.06 | |

R2O | % | 0.3max | 0.20 | |

Magnestic | % | 0.02max | 0.01 | |

Bulk density | g/cm3 | 3.50min | 3.59 | |

Absorbing water rate | % | 1.0max | 0.7 | |

Porosity rate | % | 4.0max | 3.00 | |

Grain size | mm | 5-3mm,3-1mm,1-0mm,2-1mm,1-0.5mm, 0.6-0.2mm,0.5-0mm,0.3-0mm, | ||

Fine powder | mesh | - 220mesh, -325mesh | ||

Applications

Refractories & Abrasives.

Polishing & Grinding.

Ceramic material.

Applicated for high temperature engineering equipment, construction materials.

Advantages

High Purity & Good Quality.

Good Hardness & High Heat-resistance.

Competitive Price & Reputable Supplier.

- Q:Does anyone know the refractory temperature of fire-resistant glass?

- Ordinary glass will be completely liquefied in the furnace of about 1100 degrees for half an hour and will not deform below 600 degrees. toughened glass fire-resistant glass is the product of ordinary glass after being processed Glass will mainly burst after encountering fire. When unevenly heated or encountering sudden drastic changes in temperature, ordinary glass will burst if the sharp temperature difference is over 70-120 degrees and toughened glass will burst at 200 degrees. It is not yet clear of the bursting temperature for the refractory glass. (I hope this answer can help you!) Hope you adopt !)

- Q:What refractories are resistant to fluorine gas?

- It is recommended to use fused-quartz brick, which will produce hydrofluoric acid fluorine (an acidic gas) when water vapors. It is cheap. While it is recommended to use silica?brick if it exceeds 1,200 degrees. So acidic refractory is an advisable refractory for using. It works well if the temperature is below 1200 degrees.

- Q:which kind of fire?bulkhead is better?

- General business fire endurance of two products are 3 hours. Organic fire bulkhead's main ingredient is organic material, which can be used in anti-corrosion and fireproofing cable tray. Inorganic fire?bulkhead's main ingredient is inorganic material, which mianly play a role of fireproofing. It's main ingredient is inorganic material, so it can't be used in acidproof and alkali resistant projects. Of course, the price of same amount organic fire?bulkhead in general is more expensive than the inorganic fire?bulkhead.

- Q:What are the best refractory materials in 2,400 Celsius degree?

- You can try zircon sand which has a melting point of 2430.

- Q:What is acid refractory material?

- Many kinds of refractory materials, usually by refractoriness level is divided into ordinary refractory materials (1580 to 1770 DEG C), advanced refractories (1770 to 2000 DEG C) and special refractories (more than 2000 DEG C); according to the chemical characteristics into acid refractory material, refractory materials and basic refractory materials. In addition, there are refractories for special occasions. Acid refractory with silicon oxide as the main component, are commonly used in brick and clay brick. Silica is silica containing more than 93% silica products, raw materials used in silica, silica and other waste, the acid resistance of slag erosion ability, high load softening temperature, volume shrinkage after repeated burning, or even a slight expansion; but it is vulnerable to the erosion of basic slag, low thermal shock resistance. The brick is mainly used for thermal equipment of glass furnace, coke oven, acid furnace etc.. Clay brick with refractory clay as the main raw material, containing 30% to 46% of alumina, weak acid refractory material, heat shock resistance, resistance to acid slag, widely used. Neutral refractory is mainly composed of alumina, chromium oxide or carbon.

- Q:What is the interior fireproof thermal insulation material?

- The methods of thermal insulation wall have three kinds of materials. First: gypsum board or cement board are stuck outside the polyphenyl board; second: lightweight brick build; third: infill polyphenyl board, lightweight brick is built outside. The first two has almost the same price. The latter is slightly expensive. 60 yuan / square meter is not very expensive!

- Q:What are the models of refractory cables?

- There are bout four types. 1.NA-YJV / NB-YJV Crosslinked polyethylene insulated PVC sheath A (B) class fire-resistant power cable 2.NA-YJV22 / NB-YJV22 Crosslinked polyethylene insulated steel belt braiding PVC sheath A (B) class fire-resistant power cable 3.WDNA-YJY / WDNB-YJY Crosslinked polyethylene insulated polyolefin sheath A (B) class low smoke no halogen fire retardant power cable 4.WDNA-YJY23 / WDNB-YJY23 Crosslinked polyethylene insulated steel belt braiding polyolefin sheath A (B) class low smoke no halogen fire retardant power cable

- Q:I would like to ask a friend that how much is the fire endurance of level A fireproofing glass?

- Fireproofing doors can be divided into Class A, Class B and Class C by the fire endurance, the fire endurance is seperately not less than 1.20h, 0.90h and 0.60h. Fireproofing glass is a kind of special glass which can retain its integrity and insulation in the prescribed fire test, it can be divided into three categories according to fire resistance rating: class A is the fireproofing glass with refractory integrity and refractory thermal insulation. Such glass has the properties of transmittance, fireproofing (smoke insulation, fire insulation, heat radiation shielding), sound insulation and shock resistance, which is suitable for architectural steel and wood fire doors, windows, partition walls, daylighting?roof, ceiling?screen, perspective floor and other building components required both transparent and fireproofing. Class B is a fireproofing glass with refractory integrity and thermal radiation intensity. Such fireproofing glass is mostly composite fireproofing glass with transmittance, fireproofing and smoke insulation. Class C is a fireproofing glass with refractory integrity. Such glass has the features of transmittance, fireproofing, smoke insulation and high strength. it can used in partition wall, fire window and outdoor curtain wall without the thermal insulation requirements. fireproofing glass can be divided into composite fireproofing galss and monolithic fireproofing glass by the structure.

- Q:What refractories are accessible with ease in daily life?

- Basically there have all materials. But it depends on your needs.

- Q:What level is the rock wool board fireproofing material ?

- The fire rating classification is a provision for all insulation materials, rather than to separately divide rock wool. Determine the value of the material fire rating according to the relevant test items of 8624. As the rock wool is made from basalt fusion, so it is the level A non-combustible material. And those we usually see are the mineral?cotton and glass wool, with its refractory temperature lower than the rock wool's. Rock wool board is now mainly used in wall insulation, which is a level A fire insulation material.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Tabular Alumina For Refractory With Nice Delivery Time

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t

- Supply Capability:

- 5000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords