Supply H Beam Profile with Jis Material Standard

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1. Standard: GB700-88, Q235B2.

2. Grade: Q235, SS400 or Equivalent

3. Length: 6m,10m, 12m as following table

4. Invoicing on theoretical weight or actual weight as customer request

5.Payment: TT or L/C

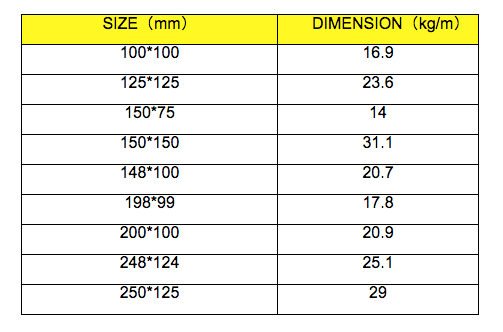

6. Sizes:

Usage & Applications of Hot Rolled Structural Steel H Beam

Commercial building structure ;Pre-engineered buildings; Machinery support structure; Prefabricated structure; Medium scale bridges; Ship-building structure. etc.

Packaging & Delivery of Hot Rolled Structural Steel H Beam

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: Can fit in the containers of 20fts the steel beams of 6M?

A2: No proble, we can put them into the containers in the form sideling.

Q3: The products are invoicing on theoritical weight or on actual weight?

A3: We can do it in both manners, according to the customers' request.

- Q:How do steel H-beams contribute to the overall architectural design of a building?

- Steel H-beams play a crucial role in the architectural design of a building, offering several important benefits. Firstly, they provide exceptional strength and load-bearing capacity, enabling architects to create structures with larger spans and handle higher vertical loads. This is vital for ensuring the building's safety and stability. Moreover, H-beams allow for flexible and versatile design options. Their shape facilitates easy connection and integration with other building materials, empowering architects to develop unique and innovative designs. Whether it is constructing large open spaces, cantilevered structures, or intricate roof designs, steel H-beams provide the necessary stability and support. Furthermore, H-beams offer a cost-effective solution for architectural design. Steel is a highly durable and long-lasting material, requiring minimal maintenance and repair throughout its lifespan. Additionally, steel H-beams are prefabricated, enabling efficient construction processes and reducing labor costs. In terms of aesthetics, steel H-beams can also enhance the visual appeal of a building. Their sleek and modern appearance can be incorporated as an architectural feature, creating an industrial or contemporary look. Additionally, H-beams can be left exposed, revealing the structural elements and adding a sense of uniqueness to the building's design. Overall, steel H-beams make significant contributions to the architectural design of a building by providing strength, flexibility, cost-effectiveness, and aesthetic appeal. Their structural capabilities allow architects to bring their creative visions to life while ensuring the safety and durability of the structure.

- Q:Are steel H-beams resistant to chemicals or corrosive substances?

- Steel H-beams are generally resistant to chemicals and corrosive substances. This is due to the inherent properties of steel, such as its high strength and durability. Steel is known for its resistance to chemical reactions and corrosion, making it a suitable material for various applications in industries where exposure to chemicals or corrosive substances is common. However, it is important to note that the resistance of steel H-beams to chemicals and corrosive substances can vary depending on the specific type of steel used and the nature of the chemicals or corrosive substances involved. In certain extreme conditions or highly aggressive environments, steel may still be susceptible to corrosion or chemical attack. To enhance the resistance of steel H-beams to chemicals and corrosive substances, additional protective measures can be applied. These may include coatings, such as galvanization or paint, which create a barrier between the steel surface and the surrounding environment. Regular maintenance and inspection are also crucial to identify and address any signs of corrosion or chemical damage promptly. Overall, while steel H-beams are generally resistant to chemicals and corrosive substances, it is important to consider the specific application and environment in order to determine the appropriate level of protection and maintenance required.

- Q:How do steel H-beams compare to timber beams in terms of sustainability?

- Sustainability differs significantly between steel H-beams and timber beams. Steel H-beams are made from recycled steel, reducing the need for new steel production and minimizing the carbon footprint in manufacturing. Moreover, steel is a durable material, resulting in longer lifespan and fewer replacements. This durability reduces waste generation and maintenance costs, making steel H-beams a more sustainable option in the long term. In contrast, timber beams have their own sustainability advantages. Timber is a renewable resource, as replanting can replace harvested trees. The production of timber beams requires less energy compared to steel H-beams. Additionally, harvesting and manufacturing timber have a lower carbon footprint and produce fewer greenhouse gas emissions compared to steel production. However, timber beams have limitations in terms of durability, fire resistance, and moisture resistance. They are susceptible to decay, insect damage, and warping, which can decrease their lifespan and increase maintenance and replacement needs. Moreover, the use of timber from unsustainable logging practices can contribute to deforestation and habitat destruction. In summary, steel H-beams offer sustainability benefits through their recycled materials, durability, and waste reduction. Timber beams, on the other hand, are renewable, require less energy in production, and have a lower carbon footprint. Ultimately, the choice between steel H-beams and timber beams should consider factors such as the specific application, local material availability, and the overall environmental impact throughout the beams' life cycle.

- Q:How do steel H-beams contribute to water conservation in buildings?

- Steel H-beams play a crucial role in water conservation in buildings through their ability to support sustainable design features such as rainwater harvesting systems and efficient plumbing systems. Firstly, steel H-beams are commonly used in the construction of roofs, where rainwater harvesting systems can be installed. These systems collect and store rainwater, which can then be used for various purposes such as flushing toilets, irrigation, and even cooling systems. By using rainwater instead of potable water for these non-potable purposes, steel H-beams indirectly contribute to water conservation by reducing the demand for fresh water. Additionally, steel H-beams are essential in the construction of plumbing systems that are designed to be water-efficient. These systems can incorporate features such as low-flow fixtures, dual-flush toilets, and sensor-activated faucets. These water-saving fixtures help reduce water consumption by minimizing the amount of water used per flush or per use. Steel H-beams provide the structural support necessary to incorporate these sustainable plumbing features into the building design. Furthermore, steel H-beams are durable and long-lasting, which reduces the need for frequent repairs or replacements. This durability translates into less water waste caused by leaks or damages to the building structure. By ensuring the stability and integrity of the building, steel H-beams contribute to water conservation by preventing water damage and subsequent water loss. In summary, steel H-beams contribute to water conservation in buildings by facilitating the installation of rainwater harvesting systems, supporting water-efficient plumbing systems, and providing structural durability to prevent water wastage. By incorporating these sustainable design features, steel H-beams help reduce the demand for fresh water and promote responsible water usage in buildings.

- Q:Do you have H steel 550x300x11x18?

- It can be made of welded H section steel. Five thousand and two hundred outbound.

- Q:How do steel H-beams perform in terms of impact resistance?

- Steel H-beams are known for their excellent impact resistance. The unique H-shaped cross-section provides a strong and rigid structure that can withstand heavy loads and impacts. This makes them highly suitable for applications where impact resistance is crucial, such as in the construction industry for supporting structures and bridges.

- Q:What are the standard lengths of steel H-beams?

- The standard lengths of steel H-beams can vary depending on the manufacturer and specific product specifications. However, in general, steel H-beams are often available in standard lengths ranging from 20 feet to 65 feet. These lengths are commonly used in construction and structural engineering applications, as they provide sufficient support and stability for various building projects. Additionally, some manufacturers may offer customized lengths based on specific customer requirements. It is always recommended to consult with the manufacturer or supplier to determine the exact standard lengths available for a particular steel H-beam product.

- Q:What is the average cost of steel H-beams?

- The average cost of steel H-beams can vary depending on various factors such as size, weight, and quality. Generally, the price range for steel H-beams falls between $500 to $2000 per ton. However, it is important to note that these prices are subject to change due to market fluctuations and individual supplier rates. Additionally, factors such as quantity and location of purchase may also affect the final cost. Therefore, it is recommended to consult with multiple suppliers and compare prices to obtain a more accurate estimate for the average cost of steel H-beams.

- Q:What's the difference between welded H - section steel and high frequency welded H - section steel and hot rolled H section steel?

- Specification and material. When the hot-rolled H steel can fully replace welding of H steel, and the former than the latter to ensure quality. In general, in the structural design of high-rise buildings, should adopt the hot-rolled H steel, steel portal frame of light steel plant, selection of welding H steel with variable cross-section steel index is better, but the project cost can not save much, the reason is that the processing capacity of hot-rolled H steel is smaller, shorter duration, if the calculation of the comprehensive economic benefits (including the project put into use), play a decisive role in the period under the condition of optional hot-rolled H steel, but when the time limit for not strict or some image project, is in line with the principle of conservation of resources selection of welding H steel.

- Q:Can steel H-beams be used in residential fence or gate structures?

- Yes, steel H-beams can be used in residential fence or gate structures. They are strong, durable, and provide excellent structural support, making them suitable for such applications.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Supply H Beam Profile with Jis Material Standard

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords