Stucco and PE Painted Aluminum coils Used for Decorations

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 300 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1.Structure of Stucco and PE Painted Aluminum coils Used for Decorations

Our stucco painted aluminum coils are widely used in decorations, such as ice-box, cars, etc.

Specification of our stucco embossed and color coated aluminium coils: thickness 0.2-0.6mm, width less than 1600mm. As for coating, we normally use PVDF coating, PE coating, etc. We can adjust coating as per customers’ requirements.

Embossed aluminum sheets have many advantages. Embossing can not only increase thickness of aluminum, but also enhance strength and rigidity of aluminum coils. Embossed & coated aluminum coils look more beautiful and widely used in decorations.

2. Main Features of Stucco and PE Painted Aluminum coils Used for Decorations

• Light Weight

• Good in strength and rigidity

• High Flatness

• Good Weathering

• Colorful

• Recycling

• Saving Energy

• Rust proof

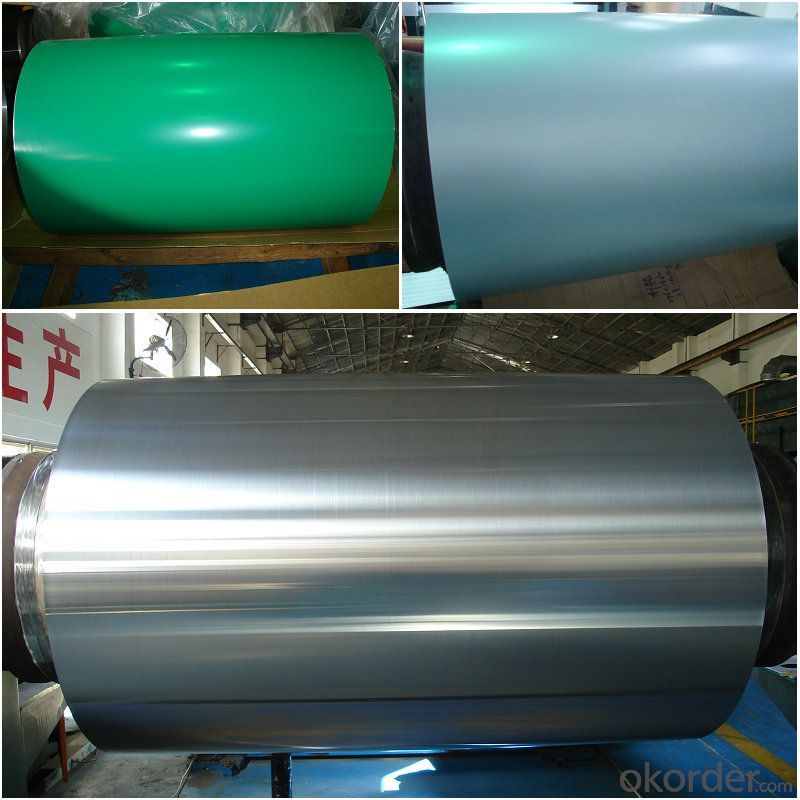

3. Stucco and PE Painted Aluminum coils Used for Decorations Images

4. Specification of Stucco and PE Painted Aluminum coils Used for Decorations

ALLOY | TEMPER | THICKNESS | WIDTH | COATING and COLOR |

3003, 3105, etc | H44, etc | 0.2-0.6mm | Less than1600mm | AS PER YOUR REQUIREMENTS |

5. FAQ

A.What about inspections to guarantee quality?

For each order, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put order in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported?

We have exported to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q:Are 101 aluminum sheets suitable for lightweight structural applications?

- Yes, 101 aluminum sheets are suitable for lightweight structural applications. Aluminum is known for its lightweight properties, making it a popular choice for structural applications where weight reduction is important. The 101 aluminum alloy is specifically designed to offer high strength and good formability, which makes it an ideal choice for various structural components. These sheets can be used in industries such as aerospace, automotive, and construction, where the focus is on reducing weight while maintaining structural integrity. Additionally, 101 aluminum sheets have good corrosion resistance, making them suitable for outdoor applications or environments with high moisture content. Overall, 101 aluminum sheets are a reliable choice for lightweight structural applications due to their strength, formability, and corrosion resistance properties.

- Q:which has greater density 5 kg of lead or 10 kg of aluminum

- The density of ANY amount of lead is greater than the density of ANY amount of aluminum. So even if we have a tiny speck of lead, and a truckload of Aluminum the lead still has greater density. The density of a substance does not depend on how much of it we have. One drop of water have a density of 1g/cm^3 and an ocean of water have exactly the same density of 1g/cm^3. The only difference is that the drop of water has less mass than the ocean, hence it would be easier to fetch; and the drop also has less volume hence it takes up less space.

- Q:Can aluminum sheets handle high temperatures?

- Certainly! High temperatures are well-tolerated by aluminum sheets. With a melting point of 660 degrees Celsius (1220 degrees Fahrenheit), aluminum proves itself suitable for various applications requiring elevated temperatures. Furthermore, aluminum possesses exceptional thermal conductivity, enabling rapid heat dissipation. This attribute renders aluminum sheets ideal for deployment in environments necessitating resistance against high temperatures, including engine components, heat exchangers, and oven linings. Nevertheless, it is crucial to take into account the specific alloy and thickness of the aluminum sheet, as different alloys may impose different temperature thresholds.

- Q:(2) when aluminium foil is dipped in mercury for a short time and then placed in water a reaction is seen to occur with hydrogen gas being one of the products.?????

- Aluminium is very reactive in air and forms a protective oxide coating. This protects it when placed in water as aluminium oxide is unreactive with water. When immersed in mercury the oxide coating is removed and therefore the aluminium itself reacts when the cleaned aluminium metal is immersed in water.

- Q:Can aluminum sheets be perforated?

- Indeed, it is possible to perforate aluminum sheets. Perforating entails either punching holes or generating a pattern of holes in a material. Aluminum, being a flexible and adaptable metal, can be easily perforated through a variety of techniques like punching, drilling, or laser cutting. The perforation of aluminum sheets can have numerous applications, including facilitating airflow, reducing weight, improving aesthetics, or constructing filtration systems. The dimensions, form, and layout of the perforations can be tailored to satisfy particular demands and design preferences. In summary, perforating aluminum sheets can effectively enhance their functionality and visual allure.

- Q:Can the aluminum sheets be used for manufacturing power transmission lines?

- Power transmission lines can be manufactured using aluminum sheets. Aluminum possesses several properties that make it suitable for this purpose. To begin with, aluminum is a lightweight material, making it more convenient to handle and transport compared to metals like copper. This can lead to reduced installation costs and increased efficiency of the power transmission lines. Additionally, aluminum exhibits good electrical conductivity, although it may not be as conductive as copper. However, due to its lighter weight, aluminum can still achieve similar electrical performance to copper while using less material. This can result in cost savings and reduced energy losses in the transmission lines. Moreover, aluminum demonstrates excellent resistance to corrosion, which is vital for power transmission lines that are frequently exposed to different weather conditions and environmental factors. Aluminum can endure harsh conditions and maintain its structural integrity over time, ensuring the reliability and longevity of the power transmission infrastructure. To conclude, aluminum sheets can indeed be utilized for the manufacturing of power transmission lines due to their lightweight nature, favorable electrical conductivity, and outstanding corrosion resistance.

- Q:Are aluminum sheets available in different colors?

- Yes, aluminum sheets are available in different colors. They can be coated or painted in various shades to suit different aesthetic preferences and design requirements. The color options range from traditional metallic finishes like silver and gold to a wide array of vibrant and contemporary colors. The availability of different colors allows aluminum sheets to be used in diverse applications such as architectural cladding, signage, automotive industry, and home décor. Additionally, the color coating or paint on aluminum sheets also provides additional protection against corrosion and enhances their durability.

- Q:What is the typical weldability of aluminum sheets?

- Aluminum sheets have good weldability due to their high thermal conductivity and low melting point.

- Q:Can 101 aluminum sheets be recycled?

- Yes, 101 aluminum sheets can be recycled. Aluminum is highly recyclable, and the recycling process for aluminum is quite efficient. By recycling aluminum sheets, valuable resources can be conserved, energy can be saved, and greenhouse gas emissions can be reduced. Recycling aluminum also helps in reducing landfill waste and the need for mining new aluminum ores. Therefore, it is recommended to recycle 101 aluminum sheets to contribute to a more sustainable and environmentally friendly future.

- Q:I bought a house with aluminum wiring. Its about 1600 square feet. I have not had any problems with the electric but I read all these story's about how terrible aluminum wiring is.. is it worth the cost to replace? Most houses on my street have it also.. they have had no problems.. house was built in 79.How much would it cost to replace? would walls have to come down to do it?

- RE: My house has aluminum wiring? I bought a house with aluminum wiring. Its about 1600 square feet. I have not had any problems with the electric but I read all these story's about how terrible aluminum wiring is.. is it worth the cost to replace? Most houses on my street have it also.. they have had no problems.. house was...

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Stucco and PE Painted Aluminum coils Used for Decorations

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 300 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords