Steel Structure with Good Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

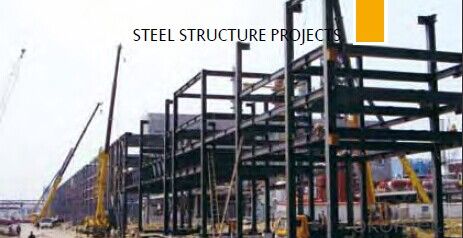

Steel Structure

Description:

1.Length of the welding withnot indication, full welding should be applied

2.Seam without indication is fillet weld, height is 0.75t

3.The cutting angle without indication, radius R=30

4.Cutting angle not specified should be

5.The diameter of the hole for the bolt if not specified, D=22

Project Reference:

For the Steel structure project of Upper part of external

piperack for air separation and gasifying facilities of

460,000 tons MTO (Methanol to Olefins) project in

Duolun, we provide about 4,500 tons steel structure. It

is a heavy chemical indusry of national energy project.

- Q:How are steel structures designed and constructed to meet LEED certification requirements?

- There are several strategies and practices that can be utilized to design and construct steel structures in order to meet the requirements for LEED certification. Here are some key elements to consider: 1. Material Selection: Steel is an incredibly sustainable material as it is highly durable, recyclable, and generates minimal waste during manufacturing. Incorporating recycled or locally sourced steel can earn LEED points in the Materials and Resources category. 2. Energy Efficiency: Steel structures can be equipped with energy-efficient features, such as high-performance insulation, efficient HVAC systems, and advanced lighting controls. These additions help to reduce energy consumption and can earn points in the Energy and Atmosphere category. 3. Indoor Environmental Quality: Steel structures can enhance the quality of the indoor environment by incorporating proper ventilation, utilizing natural light, and utilizing low-emitting materials. These elements improve air quality and occupant comfort, resulting in points in the Indoor Environmental Quality category. 4. Water Efficiency: Steel structures can be designed to include water-efficient fixtures, rainwater collection systems, and efficient irrigation systems. These strategies help conserve water and can earn points in the Water Efficiency category. 5. Sustainable Site Design: Steel structures can be designed in a way that minimizes their impact on the environment. Strategies such as stormwater management, heat island reduction, and preservation of open spaces contribute to points in the Sustainable Sites category. 6. Construction Waste Management: Proper management of construction waste is vital to achieving LEED certification. Steel structures inherently generate less waste during construction, and implementing strategies like waste sorting and recycling can earn points in the Materials and Resources category. 7. Innovation: Implementing innovative design and construction techniques, such as modular construction or advanced technologies, can further enhance the sustainability of steel structures. These innovations can earn points in the Innovation category. It's important to note that achieving LEED certification requires a comprehensive approach to design and construction. Engaging experienced professionals with LEED expertise, such as architects, engineers, and contractors, is essential to ensure the effective implementation of all necessary strategies and practices to achieve the desired certification level.

- Q:How are steel structures designed for fire resistance?

- Steel structures are designed for fire resistance through a combination of proactive measures and passive fire protection systems. One of the key aspects of designing steel structures for fire resistance is considering the behavior of steel when exposed to elevated temperatures. Steel loses its strength at high temperatures, which can lead to structural collapse if not properly addressed. To mitigate this, engineers use fire-resistant design principles to ensure that the structure can withstand the effects of fire. Proactive measures include designing the structure with fire-rated materials and employing fire-resistant coatings. Fire-rated materials, such as fire-resistant drywalls or gypsum boards, are used to create fire barriers and compartmentalize the structure. These materials help slow down the spread of fire, allowing occupants to evacuate safely and providing additional time for fire suppression efforts. Passive fire protection systems are also employed in steel structures. These systems are designed to minimize heat transfer to the steel elements, thereby preserving their structural integrity. Common passive fire protection systems include fireproofing coatings, fire-resistant insulation, and fire-resistant enclosures. These systems act as insulators, reducing the rate at which the steel is heated and extending the time for evacuation and fire control. In addition to these measures, the structural design itself takes into account factors such as load-bearing capacity and fire resistance ratings of the steel elements. Engineers perform detailed fire engineering analysis to determine critical temperatures, heat transfer rates, and structural response under fire conditions. This analysis helps determine the necessary fire protection measures and ensures that the structural design meets the required fire resistance standards. Overall, the design of steel structures for fire resistance involves a combination of proactive measures and passive fire protection systems. By considering the behavior of steel in fire and implementing appropriate fire-rated materials and coatings, engineers can create structures that are better able to withstand the effects of fire and protect occupants' safety.

- Q:How is steel used in construction?

- Due to its exceptional strength and durability, steel is extensively used in construction. It takes on various forms and serves different purposes in order to enhance the structural integrity and safety of buildings. One of its primary uses is in the creation of structural steel frames, which act as the building's skeleton and provide support and stability. Steel beams and columns are utilized to form the framework, allowing for the construction of large and open interior spaces. In addition to building frames, steel is also commonly employed in the construction of bridges and highways. Steel girders are used to span long distances and support heavy loads, ensuring the safety and durability of these infrastructure projects. Furthermore, steel reinforcement bars, or rebar, are utilized in the construction of reinforced concrete structures. The combination of steel and concrete creates a composite material that is strong and durable, capable of withstanding high pressures and forces. Steel finds its place in roofing systems, cladding, and siding as well. Steel roofing is known for its longevity, resistance to harsh weather conditions, and low maintenance requirements. Meanwhile, steel cladding and siding provide a visually appealing and protective exterior finish to buildings, making them resistant to fire, pests, and rot. Aside from its structural applications, steel is widely used for various other purposes in the construction industry. Its strength, durability, and design flexibility make it a popular choice for doors, windows, and frames. Steel pipes and tubes are utilized in plumbing, heating, ventilation, and air conditioning systems. Moreover, steel is incorporated into the construction of staircases, handrails, and other architectural elements, enhancing both the building's aesthetics and functionality. Overall, steel plays a crucial role in the construction industry due to its strength, durability, and design versatility. Its numerous applications ensure the safety, longevity, and aesthetic appeal of buildings and infrastructure projects.

- Q:How are steel structures used in solar and renewable energy projects?

- Steel structures are commonly used in solar and renewable energy projects as they provide the necessary support and stability for solar panels, wind turbines, and other renewable energy equipment. Steel's strength and durability make it an ideal choice for constructing large-scale solar farms, wind farms, and hydroelectric power plants. Additionally, steel structures can be easily customized and assembled, allowing for efficient installation and flexibility in design. Overall, steel plays a critical role in the construction and success of solar and renewable energy projects.

- Q:How are steel structures designed to accommodate security and surveillance systems?

- Steel structures can be designed to accommodate security and surveillance systems in several ways. Firstly, the structural design can include provisions for the installation of surveillance cameras and other security equipment. This may involve incorporating mounting brackets or fixing points into the steel framework, ensuring that the cameras can be securely attached to the structure. Additionally, the design can include pathways or conduits within the steel framework to accommodate the necessary wiring and cables for these systems. Furthermore, steel structures can be designed to support the weight of security equipment such as access control systems, alarms, and sensors. The strength and load-bearing capacity of steel make it ideal for supporting heavy and robust security devices. Designers can calculate and reinforce the structure to ensure that it can handle the additional weight and stress imposed by these systems. Moreover, steel structures can also be designed with security in mind by incorporating features such as reinforced doors, windows, and access points. These elements can be made from steel or reinforced with steel components to enhance their resistance to break-ins and unauthorized access. The structural design can also include measures to prevent tampering with the security systems, such as concealing wiring and equipment within the steel framework or using protective enclosures. Lastly, steel structures offer the advantage of flexibility and adaptability. They can be easily modified or expanded to accommodate future security needs. For example, if there is a need to install additional surveillance cameras or upgrade the security system, the steel structure can be easily adapted to incorporate these changes without compromising its integrity. In conclusion, steel structures can be specifically designed to accommodate security and surveillance systems by incorporating mounting brackets, pathways for wiring, and provisions for heavy equipment. They can also be reinforced to support the weight and stress of security devices and incorporate features to enhance security, such as reinforced doors and windows. Additionally, steel structures offer flexibility for future modifications and upgrades to the security system.

- Q:How are steel structures used in stadiums and sports facilities?

- Steel structures are extensively used in stadiums and sports facilities due to their strength, durability, and flexibility. They are employed in constructing the framework, supports, and roofing systems of these buildings. Steel's high load-bearing capacity allows for the creation of large open spaces without the need for excessive columns or support walls, providing unobstructed views for spectators. Additionally, steel structures can withstand extreme weather conditions and seismic activities, ensuring the safety of occupants. Overall, steel plays a crucial role in the construction of stadiums and sports facilities, enabling the creation of iconic and functional spaces for sporting events and entertainment.

- Q:What are the different types of steel stairs and elevators used in buildings?

- There are several types of steel stairs and elevators commonly used in buildings, including straight stairs, spiral stairs, curved stairs, and floating stairs. As for elevators, there are passenger elevators, freight elevators, and service elevators, each designed for specific purposes within a building.

- Q:What are the considerations for steel structure design in arctic climates?

- Careful consideration of multiple factors is necessary when designing steel structures for arctic climates in order to ensure durability and safety in the face of extreme conditions. 1. Temperature: Extremely low temperatures, sometimes dropping below -50°C, are a characteristic of arctic climates. Steel structures must be able to withstand these extreme temperatures without experiencing brittle fracture or excessive thermal expansion. Often, low alloy steels with high fracture toughness and low temperature resistance are utilized. 2. Frost heave: Frost heave occurs as a result of the freezing and thawing of the ground in arctic regions, causing significant movement and deformation of the foundation and structure. Engineers must design the foundations in a manner that mitigates the effects of frost heave, often incorporating deep foundations or insulation to prevent heat transfer between the structure and the ground. 3. Snow and ice loads: Snowfall and ice accumulation are common in arctic regions, necessitating the consideration of these loads in the design of steel structures to ensure their safe support. Designers must take into account the weight, shape, and distribution of snow and ice on the structure, as well as the potential for drifting and sliding. 4. Wind loads: Strong winds, especially in coastal areas, are prevalent in arctic climates. Steel structures must be designed to withstand these high wind speeds by taking wind loads, wind pressures, and the possibility of wind-induced vibrations into account. Adequate bracing, connections, and wind-resistant shapes are essential for ensuring structural stability. 5. Corrosion protection: Arctic climates, particularly in coastal areas, have high humidity levels and exposure to saltwater, increasing the risk of corrosion. To combat this, steel structures should be protected through the use of appropriate coatings such as galvanization or specialized paints. Regular maintenance and inspections are also necessary to prevent or address any corrosion issues. 6. Thermal insulation: In order to minimize heat loss and energy consumption, effective thermal insulation is crucial for steel structures in arctic climates. Careful selection of insulation materials and systems is necessary to prevent condensation, reduce heat transfer, and maintain comfortable indoor temperatures. 7. Construction logistics: The construction of buildings in remote arctic areas can present logistical challenges due to limited transportation, harsh weather conditions, and a scarcity of local resources. Designers must take these factors into consideration when choosing construction methods, materials, and equipment to ensure the feasibility and efficiency of the construction process. Overall, a comprehensive understanding of the unique environmental conditions and their impact on structural integrity is required when designing steel structures for arctic climates. Proper consideration of temperature, frost heave, snow and ice loads, wind loads, corrosion protection, thermal insulation, and construction logistics is crucial for ensuring the safety and durability of steel structures in these extreme environments.

- Q:What is the role of steel in environmental and sustainable buildings?

- Steel plays a crucial role in environmental and sustainable buildings due to its high strength-to-weight ratio, recyclability, and durability. It is commonly used as a structural material, allowing for lighter and more efficient building designs, which reduces material consumption and transportation emissions. Additionally, steel can be recycled repeatedly without losing its quality, making it a sustainable choice. Its durability ensures longevity, reducing the need for frequent repairs or replacements, ultimately minimizing waste generation.

- Q:What are the limitations of using steel structures in construction?

- One limitation of using steel structures in construction is their susceptibility to corrosion. Without proper protective coatings, steel can rust and weaken over time, especially in areas with high humidity or exposure to moisture. Additionally, steel structures are generally more expensive than other construction materials, which can limit their affordability for certain projects. Steel is also a highly conductive material, making it less effective in providing insulation and energy efficiency. Finally, steel structures can be challenging to modify or alter once they are in place, as they require specialized equipment and expertise for any changes or additions.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Steel Structure with Good Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords