Stainless Steel Flat Bar

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 25MT m.t.

- Supply Capability:

- 2200MT Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stainless Steel Flat Bar

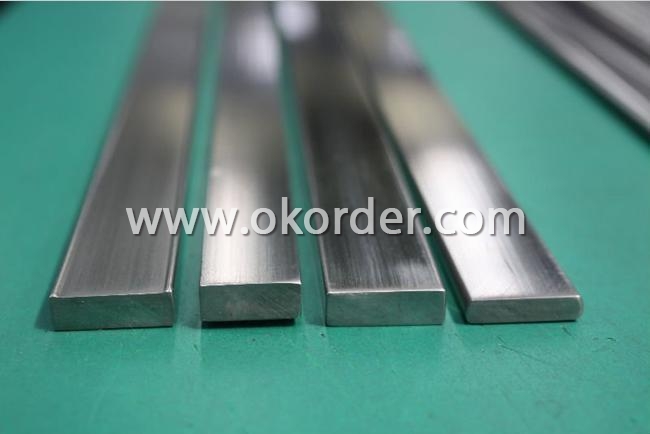

Details of Stainless Steel Flat Bar:

Thickness: 3mm - 15mm

Width: 25mm - 120mm

Inch Thickness: 1/8" - 5/8"mm

Width: 1" - 4.1/2"mm

Standard: ASTM A276/484M ,EN 10058/DIN 1017

Advantages of Stainless Steel Flat Bar :

1* All products are made of high quality material

2* More than 300 patterns

3* Favouable price&Considerable service

4* Fast delivery

5* Quickest and most efficient response to your inquiry

Specifications of Stainless Steel Flat Bar :

1. Prime stainless steel bar

2. Raw materials from TG

3. Independent factory

4. Deliverd within 3-7 days

5. Best service

- Q:What is the difference between seamless and cold-drawn stainless steel pipes?

- Seamless and cold-drawn stainless steel pipes are two different types of stainless steel pipes that vary in their manufacturing processes and properties. Seamless stainless steel pipes are manufactured without any welding or seams. They are made by piercing a solid cylindrical billet or ingot of stainless steel and then rolling it into a hollow tube shape. This seamless manufacturing process ensures that there are no weak points or areas prone to leakage, making seamless pipes highly durable and reliable. They also have a smoother interior surface, which allows for efficient fluid flow and reduces the risk of corrosion. On the other hand, cold-drawn stainless steel pipes are manufactured by pulling or drawing a solid stainless steel billet through a series of dies at room temperature. This process helps in achieving precise dimensions and a smooth surface finish. Cold-drawn pipes are typically used in applications where tight tolerances and a high-quality surface finish are required. They are known for their superior dimensional accuracy, excellent surface finish, and increased strength. In terms of properties, seamless stainless steel pipes offer better resistance to corrosion, higher strength, and increased pressure rating compared to cold-drawn pipes. The absence of welds also makes seamless pipes less prone to cracking or failure under high-pressure environments. On the other hand, cold-drawn stainless steel pipes are known for their excellent surface finish, close dimensional tolerances, and improved mechanical properties, making them suitable for applications that require precise measurements and a smooth appearance. In summary, the main difference between seamless and cold-drawn stainless steel pipes lies in their manufacturing processes, resulting properties, and applications. Seamless pipes are manufactured without any welding or seams, offering better resistance to corrosion and higher strength, while cold-drawn pipes are made by pulling solid stainless steel through dies, providing excellent surface finish, dimensional accuracy, and improved mechanical properties.

- Q:Are stainless steel pipes suitable for underground sewage systems?

- Yes, stainless steel pipes are suitable for underground sewage systems. Stainless steel pipes are known for their durability, strength, and resistance to corrosion, making them an excellent choice for underground applications. They have a long lifespan and can withstand the harsh conditions typically found in sewage systems, such as exposure to moisture, chemicals, and varying temperatures. Additionally, stainless steel pipes have a smooth interior surface, which helps prevent the buildup of debris or waste, reducing the risk of clogs or blockages. Overall, stainless steel pipes provide a reliable and long-lasting solution for underground sewage systems.

- Q:What is the difference between seamless and seamless annealed stainless steel pipes?

- The main difference between seamless and seamless annealed stainless steel pipes lies in their manufacturing process and the resulting properties of the pipes. Seamless stainless steel pipes are manufactured by piercing a hot billet or a solid bar to form a hollow cylindrical shape. This process eliminates the need for welding or any other joints, resulting in a uniform and continuous pipe with no seams. Seamless pipes are known for their excellent strength and ability to withstand high pressures, making them suitable for various applications in industries such as oil and gas, petrochemical, and construction. On the other hand, seamless annealed stainless steel pipes go through an additional heat treatment process called annealing. Annealing involves heating the pipe to a specific temperature, holding it at that temperature for a certain duration, and then cooling it slowly. This heat treatment helps to relieve internal stresses, reduce hardness, improve ductility, and enhance the overall mechanical properties of the stainless steel pipe. The annealing process also leads to the formation of a more homogenous microstructure, which further improves the corrosion resistance of the stainless steel. This makes seamless annealed stainless steel pipes particularly suitable for applications where excellent corrosion resistance is required, such as in the chemical processing, pharmaceutical, and food and beverage industries. In summary, while both seamless and seamless annealed stainless steel pipes are produced without any seams, the additional annealing process in the latter enhances its mechanical properties and corrosion resistance, making it more suitable for certain industries and applications.

- Q:What is the difference between annealed and tempered stainless steel pipes?

- Annealed and tempered stainless steel pipes are both heat-treated to enhance their properties, but they differ in terms of their mechanical characteristics and applications. Annealed stainless steel pipes are soft and ductile due to the annealing process, which involves heating the material to a high temperature and then slowly cooling it. This process relieves internal stresses and increases the steel's flexibility, making it easier to bend and form. Annealed pipes have lower hardness and strength but are more resistant to corrosion. On the other hand, tempered stainless steel pipes undergo a different heat treatment process called tempering. After being quenched, the steel is reheated to a specific temperature and then cooled rapidly. This process improves the steel's strength, hardness, and toughness, making it more suitable for applications that require high mechanical properties. Tempered pipes have higher hardness and strength but may be slightly less resistant to corrosion compared to annealed pipes. The choice between annealed and tempered stainless steel pipes depends on the specific application. Annealed pipes are commonly used in industries that require excellent corrosion resistance and flexibility, such as food processing, pharmaceutical, and chemical industries. Tempered pipes, on the other hand, are preferred in applications that require higher strength and durability, such as construction, automotive, and aerospace industries. In summary, annealed stainless steel pipes are softer and more flexible with better corrosion resistance, while tempered stainless steel pipes are stronger and harder with slightly reduced corrosion resistance. The selection of the appropriate type depends on the mechanical requirements and the environment in which the pipes will be used.

- Q:Can stainless steel pipes be used for construction?

- Yes, stainless steel pipes can be used for construction. Stainless steel is a highly durable and corrosion-resistant material, making it suitable for various construction applications. It is commonly used in plumbing systems, water supply lines, and underground piping where corrosion resistance is crucial. Stainless steel pipes are also used in constructing bridges, buildings, and infrastructure projects due to their strength and ability to withstand extreme weather conditions. Additionally, stainless steel's aesthetic appeal and low maintenance make it a preferred choice for architectural designs. Overall, stainless steel pipes are a reliable and long-lasting option for construction purposes.

- Q:Can stainless steel pipes be used for breweries?

- Indeed, stainless steel pipes find widespread application in breweries. The brewing industry favors stainless steel as the prime material for brewing equipment and piping systems owing to its outstanding resistance to corrosion, remarkable durability, and hygienic attributes. Stainless steel pipes exhibit remarkable resilience in the face of harsh and acidic conditions commonly encountered in breweries, such as elevated temperatures, alkaline and acidic cleansing agents, as well as exposure to diverse chemicals. Moreover, the simplicity in cleaning and maintenance of stainless steel pipes guarantees the production of untainted and superior quality beer. In essence, the employment of stainless steel pipes in breweries serves to ensure a brewing process that is both safe and efficient.

- Q:Are stainless steel pipes suitable for sanitary applications?

- Stainless steel pipes are indeed a great fit for sanitary purposes. The remarkable corrosion resistance, durability, and hygienic qualities of stainless steel make it the perfect option for settings that call for cleanliness and sanitation, like food processing plants, pharmaceutical facilities, and hospitals. It's worth mentioning that stainless steel pipes are non-porous, meaning they don't absorb or retain bacteria, contaminants, or odors. Moreover, they are effortless to clean and maintain, ensuring the utmost level of hygiene. Furthermore, stainless steel pipes can endure high temperatures and pressures, making them well-suited for a vast array of sanitary applications.

- Q:How do stainless steel pipes compare to cast iron pipes?

- There are two popular options for plumbing systems: stainless steel pipes and cast iron pipes. However, these two choices have notable differences when it comes to durability, cost, and corrosion resistance. To begin with, stainless steel pipes are widely recognized for their exceptional durability. They possess a higher strength-to-weight ratio and are less susceptible to cracking or breaking in comparison to cast iron pipes. Consequently, stainless steel pipes are well-suited for high-pressure scenarios or areas with heavy traffic. On the contrary, cast iron pipes have traditionally been acknowledged for their strength and longevity. They exhibit a remarkable resistance to impact and vibrations, which makes them ideal for locations where durability is of utmost importance, such as underground or in commercial buildings. Nevertheless, cast iron pipes are more prone to cracking or corrosion over time, particularly in acidic or alkaline environments. In terms of costs, stainless steel pipes generally require a higher upfront investment in contrast to cast iron pipes. Nonetheless, stainless steel pipes boast a longer lifespan and demand minimal maintenance, ultimately resulting in cost savings in the long term. Conversely, cast iron pipes may entail lower initial expenses but may involve more frequent maintenance and repairs, consequently escalating the overall costs over time. Regarding corrosion resistance, stainless steel pipes surpass cast iron pipes. Stainless steel contains a substantial amount of chromium, which forms a protective oxide layer that prevents corrosion. This characteristic renders stainless steel pipes highly resistant to rust, chemicals, and extreme temperatures. Conversely, cast iron pipes are more prone to rust and corrosion, especially if not adequately coated or maintained. In summary, stainless steel pipes offer superior durability, corrosion resistance, and long-term cost savings compared to cast iron pipes. Although cast iron pipes possess their own advantages, such as strength and impact resistance, stainless steel pipes emerge as a more reliable and versatile option for various plumbing applications.

- Q:Can stainless steel pipes be insulated with foam?

- Indeed, foam insulation can be applied to stainless steel pipes. It is a widely utilized method for insulating pipes made from different materials, including stainless steel. By providing thermal resistance, foam insulation effectively prevents heat loss or gain from the pipes. Moreover, it plays a crucial role in minimizing condensation on the pipe's surface, thus preventing corrosion. Applying foam insulation to stainless steel pipes is a simple process that involves the use of adhesive or tape. Additionally, foam insulation can be tailored to fit the precise measurements of the pipes. All in all, foam insulation proves to be a highly effective and cost-efficient solution for insulating stainless steel pipes.

1. Manufacturer Overview |

|

|---|---|

| Location | Jiangsu, China |

| Year Established | 2010 |

| Annual Output Value | above US$3 million |

| Main Markets | East Asia, Middle East. |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 50% |

| No.of Employees in Trade Department | above 10 people |

| Language Spoken: | English, Chinese |

| b)Factory Information | |

| Factory Size: | about 50000 square meter |

| No. of Production Lines | above 3 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

Stainless Steel Flat Bar

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 25MT m.t.

- Supply Capability:

- 2200MT Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords