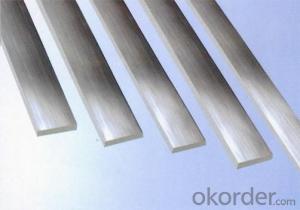

Pre Drilled Flat Bar

Pre Drilled Flat Bar Related Searches

Steel Frames For Furniture Self Tapping Screws For Steel Surface Grinding Wheels For Hardened Steel Hole Saw For Stainless Steel Step Bit For Stainless Steel Transformers For Lights In Ceiling Led Light Bulbs For Ceiling Fixtures Led Table Lamps For Home Best Solar Inverter For Rv Hot Water Bags For Pain ReliefHot Searches

Steel Mesh Panels For Sale Cheap High Tea Sets For Sale High Density Fiberboard For Sale Solar Hot Water Collectors For Sale Scaffolding For Sale In Uae Scaffolding For Sale In Ireland Scaffolding For Sale In Houston Type Of Inverter For Solar Used Solar Inverter For Sale Portable Led Signs For Sale Stone Hot Water Bottles For Sale Large Led Screens For Sale 1/4 Aluminum Plate For Sale H4 Led Headlight Bulbs For Sale Air Pump For Aquarium Price Solar Edge Inverter For Sale Aluminum Bar Stock For Sale 5kw Solar Inverter For Sale Aluminum Round Stock For Sale Bulk Solar Cells For SalePre Drilled Flat Bar Supplier & Manufacturer from China

Okorder.com is a professional Pre Drilled Flat Bar supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Pre Drilled Flat Bar firm in China.Hot Products

FAQ

- Under certain conditions, steel flat bars can warp or twist. This can happen due to factors like uneven heating or cooling during manufacturing, improper handling or storage, excessive stress during use, or if the bars are of low quality or have structural defects. Proper handling and storage of steel flat bars is crucial to avoid situations that could cause excessive stress or uneven heating/cooling. Regular inspections and maintenance can help detect signs of warping or twisting early on, enabling preventive measures to be taken to avoid further damage.

- Steel flat bars contribute to the overall sustainability of a structure by providing several key benefits. Firstly, steel is a highly durable and long-lasting material, which means that structures constructed with steel flat bars have a longer lifespan and require less frequent maintenance or replacement, reducing the overall environmental impact. Additionally, steel is a highly recyclable material, and steel flat bars can be easily recycled and reused at the end of their life cycle, making them a more sustainable choice compared to other materials. Moreover, steel has a high strength-to-weight ratio, allowing for lighter and more efficient structures, which can reduce the amount of materials needed and minimize the carbon footprint of construction projects. Overall, the use of steel flat bars enhances the sustainability of structures through durability, recyclability, and efficient design.

- Steel flat bars can be embossed using various methods. One commonly used technique is roller embossing, where the flat bar is passed between two rollers with a patterned surface. As the bar goes through the rollers, the pattern is imprinted onto its surface, resulting in an embossed design. Another method is press embossing, where the flat bar is positioned between a patterned die and a matching counter die. By applying pressure to the dies, the pattern is pressed into the bar's surface. Laser embossing is a third option, which entails utilizing a laser beam to selectively remove material from the bar's surface in a patterned way. This method allows for the creation of diverse embossed patterns, as the laser can be controlled accordingly. Furthermore, chemical embossing is also available. This involves applying a chemical solution to the bar's surface, which reacts with the metal and forms an embossed pattern. Each method possesses its own set of advantages and disadvantages. The choice of method depends on factors such as the desired pattern, design complexity, and project constraints such as cost and time limitations.

- Steel flat bars are generally resistant to chemical exposure. Steel is known for its durability and strength, making it resistant to many chemicals. However, the level of resistance can vary depending on the specific type of steel and the chemicals it is exposed to. Corrosion can occur if the steel is exposed to certain corrosive chemicals such as acids or alkalis. In such cases, it is advisable to use stainless steel flat bars which have an added layer of protection against corrosion. Additionally, the duration and concentration of the chemical exposure can also affect the steel's resistance. Taking proper precautions and regular maintenance can help prolong the lifespan of steel flat bars even in chemically exposed environments.

- Yes, steel flat bars can be used for creating stair treads or grating. Steel flat bars are often used in the construction industry due to their strength and durability. They can provide a sturdy and secure surface for both stair treads and grating applications.

- To prevent scaling or oxidation on steel flat bars during heat treatment, there are several measures that can be taken: 1. Utilize a protective atmosphere: An effective method involves subjecting the steel flat bars to heat treatment in a controlled atmosphere, such as vacuum or an inert gas environment like nitrogen or argon. This approach ensures that the steel remains isolated from oxygen, thereby minimizing the potential for oxidation. 2. Employ a protective coating: Another approach is to apply a protective coating onto the flat bars' surface prior to heat treatment. This can be accomplished by utilizing various coatings like ceramic, refractory, or metallic coatings. These coatings serve as a barrier between the steel and the surrounding atmosphere, effectively preventing oxidation. 3. Implement a reducing atmosphere: Heat treating the steel in a reducing atmosphere, such as hydrogen or a hydrogen-nitrogen mixture, can also prevent scaling and oxidation. The reducing atmosphere aids in eliminating any present oxygen and inhibits the formation of oxides on the steel's surface. 4. Control the heating process: The proper control of the heating process plays a crucial role in preventing scaling and oxidation. It is important to avoid rapid heating and cooling rates, as they can result in excessive scaling. Instead, employing slow and controlled heating with appropriate temperature ramping can help minimize the likelihood of oxidation. 5. Ensure surface cleanliness: Before heat treatment, it is essential to thoroughly clean the surface of the steel flat bars. Any contaminants, such as dirt, grease, or oils, can contribute to scaling and oxidation. Employing surface cleaning methods like degreasing, pickling, or mechanical cleaning can effectively eliminate these contaminants. By implementing these preventive measures, the risk of scaling or oxidation on steel flat bars during heat treatment can be significantly reduced, thereby ensuring the production of high-quality final products.

- Yes, steel flat bars can be used for creating supports or brackets. Steel flat bars are commonly used for their strength and durability, making them ideal for supporting heavy loads or providing structural stability. They can be easily shaped or welded to create custom brackets or supports for various applications, such as shelves, furniture, machinery, or construction projects. Steel flat bars are available in different sizes and thicknesses, allowing for versatility in design and application.

- Yes, steel flat bars can be hot-dip galvanized. Hot-dip galvanizing is a process where steel is immersed in a bath of molten zinc, which creates a protective coating on the surface of the steel. This coating helps to prevent rust and corrosion, making the steel more durable and long-lasting. Steel flat bars are commonly galvanized to enhance their resistance to environmental factors and increase their lifespan. Hot-dip galvanizing is a widely used method for protecting steel products, including flat bars, from the effects of moisture, chemicals, and other corrosive elements.