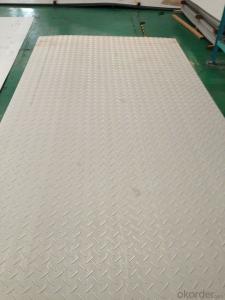

Stainless Steel 304 sheet with reasonable pricing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t

- Supply Capability:

- 1000000 m.t/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Stainless steel 304 sheet

Company advantage of stainless steel:

-Top Equipments, Leading In The Industry.

- Professional Team, Leading Innovation.

- Huge Supply Capacity Advantage, Timely and Effective Delivery.

- Modern Logistic, Fact and Convenient.

- Precise Manufacturing, Exquisite Products.

- Serve People, Create Value.

- Dimensional Network, Powerful Expansion.

Product Information of stainless steel sheet:

- Q:What is the difference between 321 and 321H stainless steel pipes?

- The main difference between 321 and 321H stainless steel pipes lies in their carbon content. 321H contains a higher amount of carbon, which improves its high-temperature strength and resistance to sensitization during welding. This makes 321H more suitable for applications requiring elevated temperatures, while 321 is typically used in lower temperature environments.

- Q:Can stainless steel pipes be used for gas distribution?

- Yes, stainless steel pipes can be used for gas distribution. Stainless steel is a highly durable and corrosion-resistant material, making it suitable for transporting gas safely and efficiently.

- Q:Can stainless steel pipes be bent or curved?

- Stainless steel pipes possess the ability to undergo bending or curving. This is due to the inherent versatility of stainless steel, which enables it to adopt diverse shapes, including bends and curves. The remarkable ductility and high tensile strength of stainless steel contribute to this flexibility. In numerous industries like construction, automotive, and manufacturing, stainless steel pipes are commonly shaped to meet specific design requirements. The desired shape and specifications determine the appropriate bending method, which can include hot bending, cold bending, or mandrel bending. It is crucial to emphasize that the bending or curving of stainless steel pipes necessitates the use of proper equipment and expertise. This ensures the preservation of the pipe's integrity and quality.

- Q:Can stainless steel pipes be used for seawater applications?

- Seawater applications can indeed utilize stainless steel pipes. Stainless steel possesses exceptional resistance to corrosion and can endure the severe conditions that seawater presents, rendering it an optimal material for marine pipes. The presence of chromium within stainless steel fosters the creation of a safeguarding oxide layer on the pipe's surface, effectively preventing corrosion and ensuring its longevity. Moreover, stainless steel pipes exhibit commendable strength and can effectively handle high-pressure circumstances, thereby making them highly suitable for diverse seawater applications like desalination plants, offshore oil rigs, and shipbuilding endeavors.

- Q:How do you calculate the wall thickness for stainless steel pipes under external pressure?

- When calculating the wall thickness for stainless steel pipes under external pressure, various factors such as material properties, design codes, and applied external pressure must be taken into account. Here is a general method for calculating the wall thickness: 1. Identify the design pressure: Begin by determining the external pressure that the stainless steel pipe will experience. This pressure may be caused by factors like fluid flow, environmental conditions, or operational requirements. 2. Determine the properties of the material: Stainless steel pipes come in different grades, each with its own mechanical properties. Consult the material specifications to find the values for the yield strength (Sy) and ultimate tensile strength (Su) of the specific stainless steel grade being used. 3. Establish the allowable stress: The allowable stress (Sa) is the maximum stress that the material can handle under the given conditions. This information is usually provided by design codes or standards like ASME B31.3 for process piping or ASME Section VIII for pressure vessels. 4. Calculate the thickness for design pressure: Use the following formula to calculate the thickness required for design pressure (t): t = (P * D) / (2 * Sa) P represents the design pressure and D is the outside diameter of the stainless steel pipe. 5. Determine the corrosion allowance: Since stainless steel is prone to corrosion, it is important to consider a corrosion allowance to ensure the pipe's longevity. The design codes or industry standards typically specify the corrosion allowance. 6. Calculate the final wall thickness: Add the corrosion allowance to the thickness calculated for design pressure in step 4 to obtain the final wall thickness. It is important to note that this is a general method, and specific design codes or standards may have additional requirements or factors to consider. Therefore, it is recommended to consult the relevant design codes, standards, or a qualified engineer to ensure accurate and safe calculations for your specific application.

- Q:Can stainless steel pipes be used for HVAC systems?

- Yes, stainless steel pipes can be used for HVAC systems. Stainless steel is a durable and corrosion-resistant material that is suitable for various applications, including HVAC systems. It offers excellent strength and reliability, making it an ideal choice for transporting fluids and gases in HVAC systems. Additionally, stainless steel pipes can withstand high temperatures and maintain their integrity, ensuring efficient and long-lasting performance in HVAC installations.

- Q:Are stainless steel pipes resistant to stress corrosion cracking?

- Yes, stainless steel pipes are generally resistant to stress corrosion cracking. Stainless steel is a corrosion-resistant material that contains high levels of chromium and nickel, which help to protect against corrosion and other forms of degradation. Stress corrosion cracking occurs when a combination of tensile stress, a corrosive environment, and a susceptible material is present. However, stainless steel has good resistance to stress corrosion cracking due to its composition and inherent properties. It can withstand high levels of stress without significantly degrading or cracking, making it a suitable material for applications that require durability and resistance to corrosion.

- Q:How do stainless steel pipes compare to aluminum pipes?

- Stainless steel pipes and aluminum pipes have their own unique properties and advantages, making them suitable for different applications. One major difference between stainless steel pipes and aluminum pipes is their corrosion resistance. Stainless steel pipes are known for their exceptional corrosion resistance, which makes them ideal for applications where the pipes come into contact with corrosive substances such as chemicals or saltwater. On the other hand, aluminum pipes are not as resistant to corrosion as stainless steel and are more prone to oxidation. However, aluminum pipes can be made more corrosion-resistant through various coatings or treatments. Another important factor to consider is the strength and durability of the pipes. Stainless steel pipes are generally stronger and more durable than aluminum pipes. They can withstand higher pressure and temperature, making them suitable for high-stress applications such as industrial piping systems or transportation of fluids and gases. Aluminum pipes, although less strong than stainless steel, are lightweight and offer good strength-to-weight ratios, making them suitable for applications where weight is a concern, such as aerospace or automotive industries. Cost is another aspect to compare. Stainless steel pipes are usually more expensive than aluminum pipes due to the higher cost of raw materials and manufacturing processes. However, stainless steel pipes have a longer lifespan and require less maintenance, which can offset the initial higher cost in the long run. Aluminum pipes are generally more affordable, but they may require more frequent maintenance and replacement due to their lower resistance to corrosion and wear. In terms of appearance, stainless steel pipes have a sleek and polished look, while aluminum pipes can be either anodized or painted to achieve different finishes. The choice between the two would depend on the aesthetic preferences of the specific application. In summary, stainless steel pipes offer superior corrosion resistance, strength, and durability, making them suitable for demanding applications. Aluminum pipes, on the other hand, are lightweight and cost-effective, making them a preferred choice in industries where weight is a concern. Ultimately, the choice between stainless steel pipes and aluminum pipes depends on the specific requirements of the application, taking into account factors such as corrosion resistance, strength, cost, and aesthetics.

- Q:What is the difference between schedule 40 and schedule 80 stainless steel pipes?

- Stainless steel pipes are categorized into schedule 40 and schedule 80 based on their wall thickness. The primary distinction between the two lies in their pressure ratings. Schedule 40 pipes possess a lower pressure rating and are suitable for applications with low to medium levels of pressure. Conversely, schedule 80 pipes have a higher pressure rating and are utilized in high-pressure scenarios. The increased wall thickness of schedule 80 pipes enables them to handle elevated pressure levels, rendering them preferable for situations where the pipe necessitates enduring heightened stress or conveying fluids and gases at higher pressures. These pipes find common usage in industrial environments like oil refineries, chemical plants, and power plants, which are known for their corrosive atmospheres and high-pressure requirements. In contrast, schedule 40 pipes are more commonly employed in residential and commercial settings such as plumbing systems, water supply lines, and HVAC systems, where lower pressure demands are usually encountered. To ensure secure and efficient operation, it is crucial to carefully consider the specific requirements of the project and seek advice from a professional in order to determine the appropriate schedule of stainless steel pipe.

- Q:What is the density of stainless steel pipes?

- Depending on the specific grade of stainless steel, the density of stainless steel pipes may differ. Nevertheless, stainless steel pipes typically have a density range of 7.9 to 8.0 grams per cubic centimeter (g/cm³). Compared to other materials, this density is relatively high, which enhances the strength and durability of stainless steel pipes.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Stainless Steel 304 sheet with reasonable pricing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t

- Supply Capability:

- 1000000 m.t/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Hot Searches

Related keywords