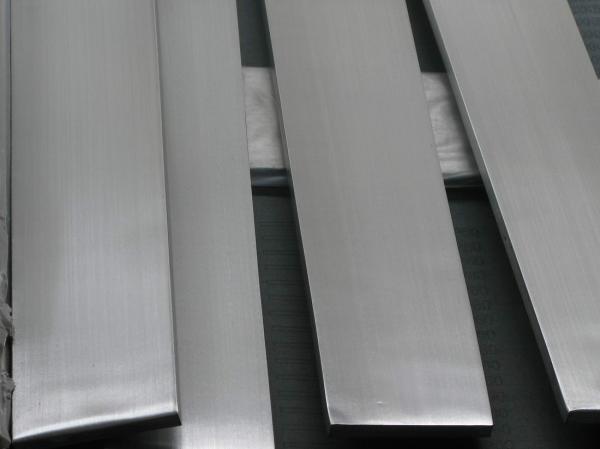

SUS 304 Stainless Steel Flats

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Ton m.t.

- Supply Capability:

- 2000 Tons Per MONTH m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stainless Steel Flats

1. Standard: AISI, GB, JIS, ASTM, DIN, EN

2. Grade:

1).200Series: 201,202.

2).300Series: 301,302,303,304,304L,316,316L,321.

3).400Series: 410,410S,416,420,430,430F.

3. Size:3x25mm- 80x250mm

4. Length: 2m-6m

5. Craft: HRAP, or cold drawn

6. Stainless Steel Flat Bar Surface: Pickling or polished

7. MOQ: 1000kg

8. Delivery: within 20 days

9. Package: Waterproof with tape

10. Application: These products are widely supplied to areas of machine-made industry, chemical industry, shipping industry,architecture, food industry, household products etc.

|

Name |

Stainless Steel Flat Bar | ||||||||

|

Material |

201.202.301.304.304L,304N,304LN, 309S,310S,316,316L, 316Ti,316N,316LN,317,317L,347, 347H,etc. | ||||||||

|

Standard |

JIS/AISI/ ASTM,/GB,/DIN,/EN/SUS.etc. | ||||||||

Shape |

Stainless steel Round/flat/square/angle/hexagonal bar | ||||||||

Price term |

FOB/CIF/CNF or as required | ||||||||

|

Length |

6m,5.8m,4m as required | ||||||||

|

Application |

kitchen and sanitary wares , and Structural use high strength components,furniture handles , handrails , electroplating and electrolyzing pendants , foods, electron , petroleum , construction and decoration , etc | ||||||||

|

Payment terms |

L/C,T/T,Western Union,or as required. | ||||||||

|

MOQ |

As required | ||||||||

|

Packing |

Export standard package | ||||||||

|

Certificate |

ISO/SGS | ||||||||

|

Contact |

If you are interested in our products,please feel free to contact me. |

- Q:How are stainless steel pipes manufactured?

- Stainless steel pipes are manufactured through a multi-step process that involves various stages of fabrication and shaping. The manufacturing process begins with the selection of high-quality stainless steel, usually in the form of sheets or coils. These steel sheets are thoroughly inspected for any defects or imperfections before being cut into the desired length or size. Once the sheets are cut, they are fed into a forming machine where they are rolled into the shape of a cylindrical tube. This process is known as cold rolling, and it helps to give the pipe its initial shape and thickness. The rolled sheets are then welded together using either a high-frequency induction welding technique or a submerged arc welding method. Both methods ensure a strong and durable weld joint. After the welding process, the pipe goes through a series of finishing treatments to improve its appearance and physical properties. The first step is to remove any excess weld material using a trimming machine. This ensures a smooth and even surface along the length of the pipe. Next, the pipe is subjected to a heat treatment called annealing. Annealing helps to relieve internal stresses and improve the pipe's mechanical properties. It also enhances the corrosion resistance of the stainless steel. Following annealing, the pipe may undergo additional processes such as pickling and passivation. Pickling involves immersing the pipe in an acid solution to remove surface impurities and oxides. Passivation, on the other hand, involves treating the pipe with a chemical solution to create a protective oxide layer on its surface, enhancing its resistance to corrosion. Once the finishing treatments are complete, the pipes are cut to the desired length and undergo a final inspection for quality assurance. This involves checking dimensions, surface finish, weld integrity, and overall appearance. In conclusion, stainless steel pipes are manufactured through a meticulous process that includes cutting, forming, welding, finishing treatments, and quality control measures. This ensures that the pipes meet the required standards and exhibit excellent properties such as strength, durability, and corrosion resistance.

- Q:How do you cut stainless steel pipes?

- Stainless steel pipes can be cut using a variety of methods such as using a hacksaw, a reciprocating saw with a metal-cutting blade, or a pipe cutter specifically designed for stainless steel. It is important to choose the appropriate tool and blade for the job, ensuring a clean and precise cut without damaging the pipe's integrity.

- Q:What is the maximum temperature stainless steel pipes can handle?

- The specific grade of stainless steel being utilized determines the maximum temperature that can be endured by stainless steel pipes. Generally, stainless steel possesses a reputation for its exceptional resistance to high temperatures and can maintain its structural integrity within a temperature range of -150°C (-238°F) to 1100°C (2012°F). Yet, the precise maximum temperature differs depending on variables including the grade of stainless steel, the intended use, and the length of time exposed to elevated temperatures. To ascertain the maximum temperature limit for a specific stainless steel pipe, it is crucial to refer to the manufacturer's specifications and guidelines.

- Q:Can stainless steel pipes be used for underground drainage systems?

- Yes, stainless steel pipes can be used for underground drainage systems. Stainless steel is durable, corrosion-resistant, and can withstand the harsh underground conditions, making it a suitable choice for underground drainage systems.

- Q:Can stainless steel pipes be mirror polished?

- Yes, stainless steel pipes can be mirror polished.

- Q:Are stainless steel pipes suitable for marine environments?

- Indeed, stainless steel pipes prove to be an excellent choice for marine environments due to their high suitability. With their corrosion and rust resistance, stainless steel emerges as an ideal material for deployment in marine settings, where constant exposure to saltwater, moisture, and other adverse conditions prevails. The inclusion of chromium in stainless steel results in the creation of a protective layer on its surface, effectively preventing the emergence of rust and corrosion. Consequently, these pipes exhibit remarkable longevity and durability, even when subjected to highly corrosive marine environments. Moreover, stainless steel pipes offer outstanding strength and impact resistance, rendering them highly reliable for a multitude of marine applications, including shipbuilding, offshore platforms, and marine structures.

- Q:What is the difference between 2507 and 316 stainless steel pipes?

- The main difference between 2507 and 316 stainless steel pipes is their composition and properties. 2507 stainless steel is a duplex stainless steel alloy that contains higher levels of chromium, molybdenum, and nitrogen compared to 316 stainless steel. This makes 2507 more resistant to corrosion, especially in harsh environments like seawater or chloride-containing solutions. Additionally, 2507 has higher tensile and yield strengths, making it more durable and suitable for applications that require higher strength and resistance to stress cracking. On the other hand, 316 stainless steel is an austenitic stainless steel alloy that offers good corrosion resistance and is widely used in various industries. Overall, the choice between 2507 and 316 stainless steel pipes depends on the specific application requirements and the level of corrosion resistance and strength needed.

- Q:Are stainless steel pipes suitable for chemical storage tanks?

- Yes, stainless steel pipes are suitable for chemical storage tanks. Stainless steel is highly resistant to corrosion, making it an ideal choice for storing and transporting chemicals. It can withstand exposure to various chemicals, acids, and alkalis without deteriorating or contaminating the stored substances. Additionally, stainless steel pipes have high tensile strength and can withstand high pressure, making them a reliable option for chemical storage tanks that require durability and safety.

- Q:Can stainless steel pipes be used for breweries?

- Yes, stainless steel pipes are commonly used in breweries. Stainless steel is the preferred material for brewing equipment and piping systems due to its excellent corrosion resistance, durability, and hygienic properties. Stainless steel pipes can withstand the harsh and acidic conditions present in breweries, such as high temperatures, alkaline and acidic cleaning agents, and exposure to various chemicals. Additionally, stainless steel pipes are easy to clean and maintain, ensuring that the beer produced remains uncontaminated and of high quality. Overall, the use of stainless steel pipes in breweries helps to ensure a safe and efficient brewing process.

- Q:Can stainless steel pipes be heat treated?

- Indeed, heat treatment is applicable to stainless steel pipes. The procedure entails subjecting the stainless steel pipe to a particular temperature, maintaining it at that temperature for a specific duration, and subsequently cooling it in a controlled manner. This method is commonly employed to modify the mechanical properties of the stainless steel, such as enhancing hardness or bolstering strength. Furthermore, heat treatment can address stress relief and eliminate impurities in the stainless steel pipe. However, it is crucial to acknowledge that not all stainless steel grades can undergo heat treatment, as the composition of the alloy significantly influences its heat treatability. Therefore, it is advisable to consult the manufacturer or a metallurgical expert to ascertain the appropriate heat treatment process for a specific stainless steel pipe.

1. Manufacturer Overview |

|

|---|---|

| Location | Hebei,China |

| Year Established | 2009 |

| Annual Output Value | Above US$1 million |

| Main Markets | Asia, Middle East,America |

| Company Certifications | CE, CCC, ISO90001 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 0.3 |

| No.of Employees in Trade Department | 4 People |

| Language Spoken: | English;Chinese |

| b)Factory Information | |

| Factory Size: | Above 5,000 square meters |

| No. of Production Lines | 3 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Lower |

Send your message to us

SUS 304 Stainless Steel Flats

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Ton m.t.

- Supply Capability:

- 2000 Tons Per MONTH m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords