Solar Panel Monting System TT-DR2

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 50万套 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

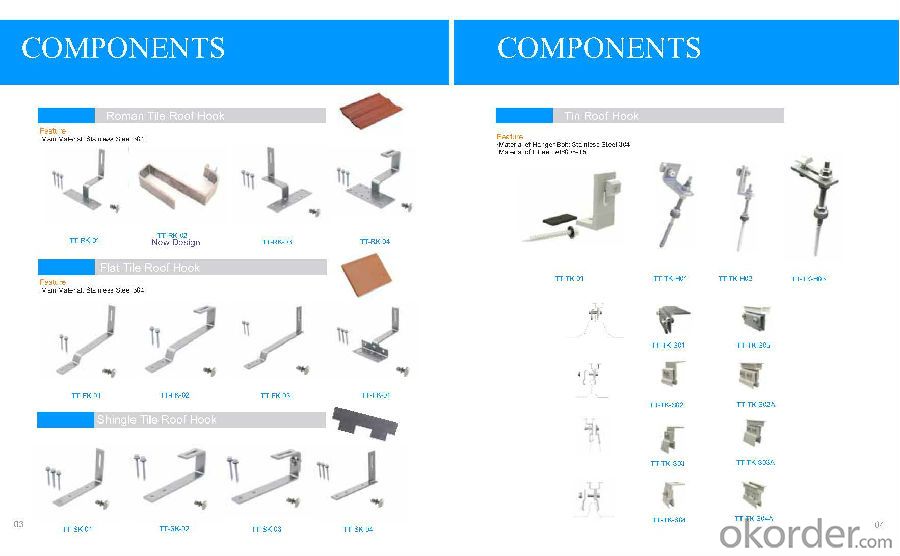

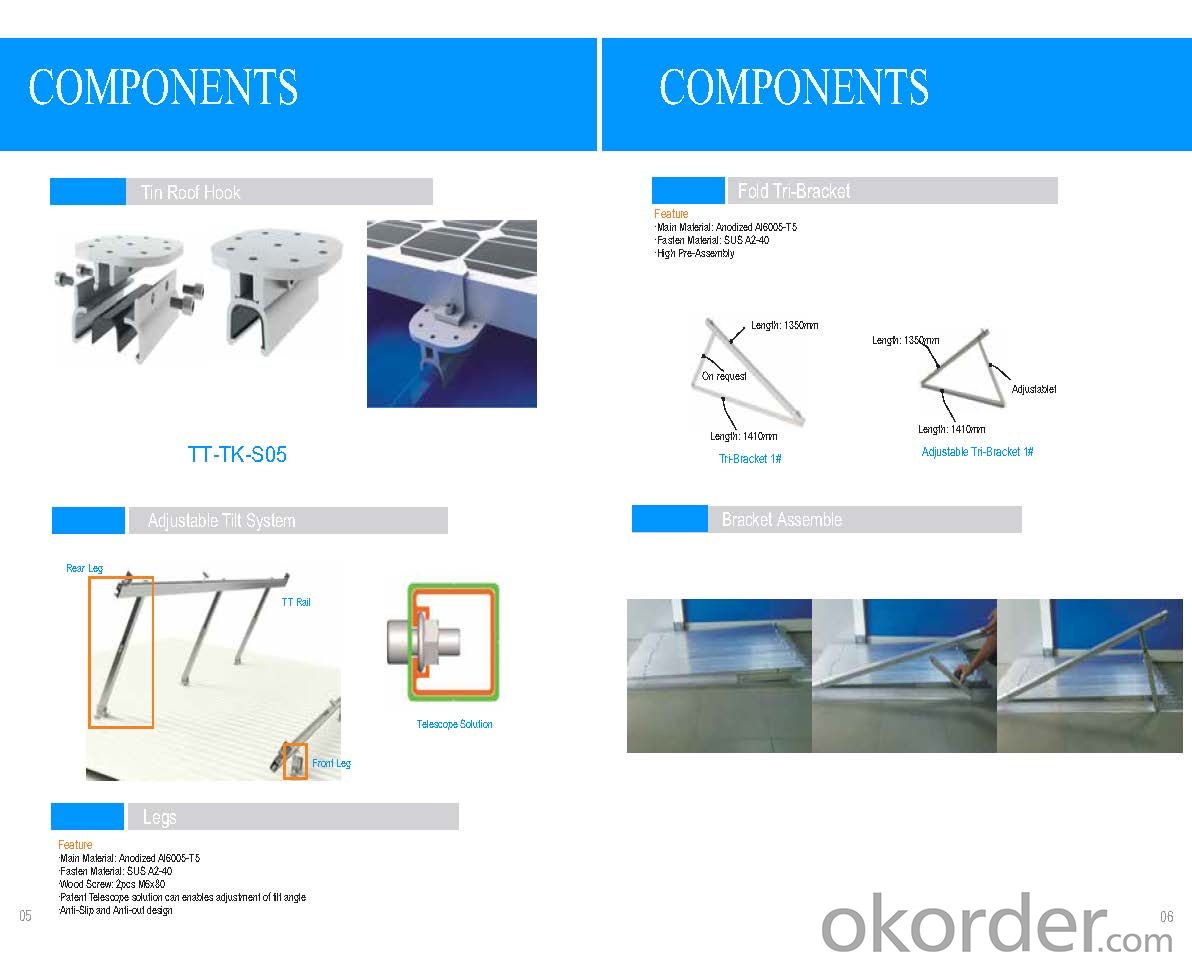

PV Mounting brackets are special solar photovoltaic systemfor placing, installing, fixing the solar panel design. Generally materials arealuminum, steel structure, stainless steel. PV mounting products at groundmounting system, flat roof mounting system, adjustable angle roof rack system,inclined roof rack system, column bracket system.

The Ground Mounting System including concret basement sysytemand steel pipe sysytem, Titanergy provides total solution for flat or pitchedroof with patent products.On the basis of the given project data, specificnational standards and guidelines, Titanergy will calculate the completestructural analysis and create a complete project plan to make sure reliablestructural safety.We provide high quality HDG steel and aluminum products forthe ground mounting sysytem,witch can make sure the security and durability ofthe project.

Features and Advantages

n The rail bracket is easy to install, just use simple tools(eg, Allen wrench) can be easily installed. Rail connecting member can freelyadjust the length, the stent may be pre-installed on the roof, and thenappropriately adjusted according to the size of the solar panel.

n The combination of strong, aluminum rails and card blocks fora variety of venues and a variety of materials roofs (such as metal, ceramicand other kinds of tile surface)

n Component compatibility, and rail can meet PV modules fromdifferent manufacturers.

n accuracy, the length of the rail to the nearest millimeter,the construction process, not because of the length is too long or too shortfor the second cut.

n flexible assembly, rail hooks can adjust the spacing modulearray and tile has been installed successfully address the uneven roofconstruction led to difficult problems.

n design standards, product design and development process instrict accordance with GB, the German standards and other internationalstandards to ensure products reach the world advanced level.

n Quality assurance, the stent main material is high-qualityaluminum and stainless steel, effectively prevent corrosion of oxidation.Products can be recycled, reducing environmental pollution.

n Carried out strictly according to the current specificnational standards

n Perfectly optimized components and complete structuralanalysis for the sysytem

n High corrosion resisitance ensure the stability and highdurability

n Total test and certification make sure the high quality ofthe products

n Maximum pre-assembled in factory,quick mounting onsite,timesaving

10-year durability warranty

Technical Data

n Design Period:25 years

n Installation Site: Open area

n Array Angle:10°~60°

n ModuleType:Framed or unframed

n Material:Q235B,Al 6063-T5,Al 6005-T5,StainlessSteel A2-70

n Coating:HDG/Anodised

- Q:Can solar mounting systems be installed on rooftops with satellite dishes?

- Yes, solar mounting systems can be installed on rooftops with satellite dishes. However, it is important to ensure that the satellite dish is not obstructing the optimal placement of the solar panels. Proper positioning and coordination between the solar mounting system and satellite dish can be done to ensure both systems can coexist on the rooftop.

- Q:What are the environmental impacts of solar mounting systems?

- Solar mounting systems have several environmental impacts. Firstly, the production of these systems requires raw materials such as steel and aluminum, which entail mining and extraction processes that can contribute to habitat destruction and pollution. Additionally, the manufacturing of these systems may produce greenhouse gas emissions and waste. However, it is important to note that once installed, solar mounting systems have minimal ongoing environmental impacts. They generate clean and renewable energy, thus reducing dependence on fossil fuels and mitigating air pollution and greenhouse gas emissions. Furthermore, they have a long lifespan and can be recycled at the end of their use, minimizing waste generation. Overall, while there are some initial environmental impacts associated with their production, solar mounting systems have a significantly positive environmental impact in terms of energy generation and carbon footprint reduction.

- Q:What are the benefits of using a solar mounting system?

- There are several benefits of using a solar mounting system. Firstly, it allows for optimal positioning and orientation of solar panels, maximizing their exposure to sunlight and thus increasing energy production. Secondly, it provides a secure and durable support structure, protecting the panels from external factors such as wind, snow, and vandalism. Additionally, a well-designed mounting system can be easily installed and adjusted, making maintenance and cleaning of the panels more convenient. Finally, using a solar mounting system promotes sustainability by utilizing renewable energy sources and reducing carbon emissions, contributing to a greener and more sustainable future.

- Q:Can a solar mounting system be adjusted to optimize sunlight exposure?

- Yes, a solar mounting system can be adjusted to optimize sunlight exposure. By adjusting the angle and orientation of the solar panels, the system can maximize the amount of sunlight received, improving the overall efficiency and performance of the solar energy system.

- Q:Can a solar mounting system be installed on a rooftop with a wood shake roof?

- Yes, a solar mounting system can be installed on a rooftop with a wood shake roof. However, it is essential to ensure that the installation is done by professionals who can properly secure the mounting system and take necessary precautions to protect the integrity of the roof.

- Q:Are there any specific requirements for water heater or thermal system integration when using a solar mounting system?

- Yes, there are specific requirements for water heater or thermal system integration when using a solar mounting system. The solar mounting system should be designed and installed in a way that allows for proper positioning and orientation of the solar panels to maximize sunlight exposure. Additionally, the system should have the necessary plumbing connections and controls to efficiently transfer the heat collected by the solar panels to the water heater or thermal system. Proper insulation and sizing of the water storage or thermal system are also important considerations for effective integration.

- Q:Can a solar mounting system be used on floating platforms?

- Yes, a solar mounting system can be used on floating platforms. Floating solar systems, also known as floating photovoltaic (FPV) systems, utilize specially designed mounting structures that can be secured to floating platforms such as pontoons or rafts. These systems are typically used on bodies of water like lakes, reservoirs, or ponds, providing an efficient and innovative way to harness solar energy.

- Q:What are the disadvantages of using a ground-mounted solar system?

- Some disadvantages of using a ground-mounted solar system include the need for a large amount of space, potential shading issues from nearby structures or vegetation, higher installation and maintenance costs compared to rooftop systems, and the possibility of land-use conflicts in certain areas.

- Q:Are there any specific requirements for facade or cladding design when using a solar mounting system?

- Yes, there are specific requirements for facade or cladding design when using a solar mounting system. These requirements typically include considerations such as the structural integrity of the facade or cladding, the ability to support the weight of the solar panels and mounting system, proper waterproofing and insulation, and ensuring sufficient ventilation and airflow around the panels. Additionally, the design should also take into account any aesthetic considerations and the overall architectural integration of the solar panels with the building's facade or cladding.

- Q:Can a solar mounting system be installed on a rooftop with a torch-down roof?

- Yes, a solar mounting system can be installed on a rooftop with a torch-down roof. Torch-down roofs are typically made of modified bitumen membrane, which provides a durable and waterproof surface for solar panel installation. However, it is important to consult with a professional solar installer to ensure proper installation techniques and to assess the structural integrity of the roof.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Solar Panel Monting System TT-DR2

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 50万套 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords