Soft/Tight Yarn Cone Winder Machine for Textile

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 10 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Application:

Soft/Tight Yarn Cone Winder Machine for Textile is used to waxing the yarn in hosiery mill and woolen mill. It can used with computerized flat knitting machine and large diameter circular knitting machine.

Main features of Soft/Tight Yarn Cone Winder Machine for Textile:

1. Vertical winder path with no inflection point, little friction and less hairiness. It is appropriate for high speed waxing winding. The speed of waxing is twice as much as that of traditional table-type at least.

2. Using brushless DC moter with longer axis,it is converient to adjust the speed of single spindle.It can provide different winding speed for various yarns.

3. Double points waxing system with micro motors. The forming of cheese is better.

4. Using high quality alloy drums with optimized groove shape ,which has the advantages of good anti-overlapping characteristics, light weight, good wear resistance, and static elimination.

5. Single winding motor control for each spindle

6. High-speed creel with gas spring, which can keep constant winding pressure. This creel is stable and reliable.

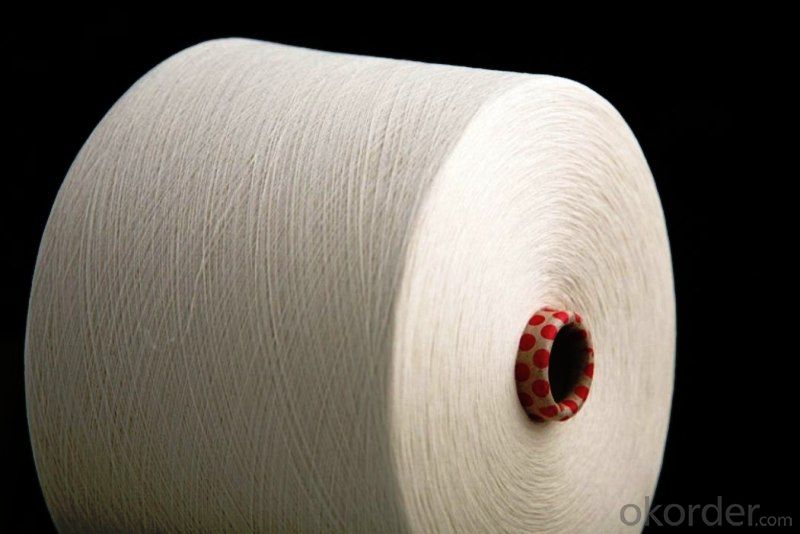

Product Pinctures of Soft/Tight Yarn Cone Winder Machine for Textile:

Package and Shipping:

Specification:

| Items | Technical Parameters |

| Types of winding | Drum,Random |

| Mechanical speed | Up to 800m/min |

| Package shape | Cylindrical or conical |

| Traverse length | 230mm,280mm |

| Package bobbin | Cylindrical or conical of 3°30' |

| Package diameter | Up to φ 290 mm |

| Package density | 0.2-0.4g/cm3 |

| Yarns / count | Cotton.flax,wool, silk,chemical fiber /Ne 6…180 |

| NO.of spindles | 2,4,6 spindles per section for select |

FAQ of Soft/Tight Yarn Cone Winder Machine for Textile:

· Q:What is the machine used for?

A:Soft/Tight Yarn Cone Winder Machine for Textileis suitable for processing PP, PE split film yarn/ just twine, cotton twine, weaved twine to ball.

· Q: What is the MOQ?

A: 1 set.

· Q: What is the lead time of the product?

A: 5-20 days after payment

- Q:What is spinning down?

- The emergence of spinning has not only changed the original society of textile production, the development of later spinning tool is very far-reaching, and it as a simple spinning tool, has been used for thousands of years

- Q:What is a pedal loom?

- The pedal loom is a generic term for a textile machine with a pedal

- Q:When did Chinese ancient textile technology come from? Why does Europe call China "silk country"?

- Indicating that more than 3400 years ago, our people have mastered the bark fiber degumming technology. These linen textile level has been equivalent to more than a thousand years after the Western Han Dynasty maw heap of the tomb of linen

- Q:Textile equipment to protect the work is not a special type of work?

- Second, the former Ministry of Textile Industry "on the trial" textile industry chemical fiber toxic and hazardous operations early retirement range "notice [(88) spinning word No. 19) document, the viscose fiber 33 jobs (carbon disulfide manufacturing Workers, calcium sulphate liquid preparation workers, diggers, detergents, bleach, sulfonation, plate and frame filter workers, spinning workers, filament twist and drop silk workers, filament head workers, filament silk Workers, cellophane workers, iron chrome salt manufacturing workers, cotton linen preparation workers, bleach workers, carbon disulfide library workers, carbon disulfide safety workers, short fiber post-processing workers, carbon disulfide recycling workers, precision workers and spinneret finishing workers , Outside the precision workmanship, the strength of wire accessories replacement workers, waste silk cleaners, strong wire tube finishing workers, strong wire metering pump complete work, strong wire grading workers and loading and unloading silk workers, strong wire packer, strong wire early twist Block machine, strong silk weaving workers, strong silk with plastic workers, sulfonation machine and spinning machine to protect workers, acid station acid bath workers, acid station security workers) as toxic and hazardous special types of work and the four types of work (not Including mechanical operators Of the unloading of carpenters, log porter, turning carpentry, split woodworking) as a particularly heavy manual labor special work

- Q:China's textile industry prospects of printing and dyeing ?

- Foreign-funded enterprises in addition to the equipment for the Chinese market, but also a large number of exports, and even anti-sales back to the country of origin. China is moving from one of the largest textile machinery market demand to Asia Textile Machinery Manufacturing Center, and even the world textile machinery manufacturing center.

- Q:What is a spinning wheel?

- While the pedal spinning wheel drive the power of the spinning wheel from the foot, the operation, the spinning woman can use both hands for spinning operation, greatly improving the work efficiency. Since its inception, spinning gear has been the most popular spinning machine, even in modern times, some remote areas still use it as the main spinning tool.

- Q:What is the historical background of the mechanization of the British cotton textile industry?

- Technology: Accumulation of workshop handicraft technology;

- Q:Textile machinery production process is probably what kind of?

- And then the processing of a good machine frame is the initial installation of the wall after the installation (here first to do the foundation).

- Q:What modern textile machinery?

- Spinning equipment is divided into processing short fiber and processing long fiber two categories.

- Q:What is the current status of the textile industry?

- The global textile industry market uncertainty is increasing, which with the global credit crisis and the United States, the EU economic growth slowdown in the trend will bring impact on the clothing retail industry. The dollar outreach, crude oil prices ups and downs and China's textile exports to Europe will lift the limit, are declared a major change. By the US economic slowdown, corporate sales will decline. And because the United States, Europe may implement new trade barriers, so the global textile industry procurement may be a significant change in the trend. In addition, there are less than 3 months, for the textile and apparel products quota system will end. This international textile and apparel trade system changes are the latest challenges faced by textile and garment enterprises, not only with hope and opportunity, but also with a great risk.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Soft/Tight Yarn Cone Winder Machine for Textile

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 10 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products