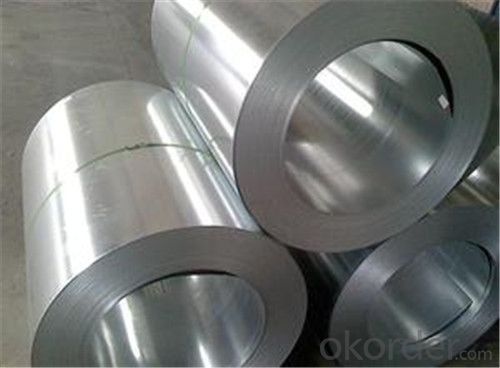

Rolled Steel Coil / Sheet / Plate SPCC in CNBM from China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

The raw material of cold rolled steel coil/sheet is high quality hot rolled product, and after pickling, kinds of new technology and new process of global cold rolling production have been applied. Therefore the manufacturing, home appliance, automobile etc.

Specification:

COLD ROLLED STEEL | |

Thicknenss | 0.10mm-4.00mm |

Width | 600mm-2000mm |

Sheets length | 1200-6000mm |

Coil inner diameter | 508-610mm |

Surface treatement | matt finish/bright finish,oiling/dry, bright anneal/black anneal |

Coil weight | 3-5t |

Characteristic:

Quality of the goods could be guaranteed. The finished product has a variety of excellent capabilities, such as continuous rolling, degreasing, annealing, skin pass, slitting and cut to length line etc. Along with it many rocessing capability and smooth, flat surface. It’s widely used in outdoor and interior decoration, furnishing

Details:

We can ensure that stable quality standards are maintained, strictly meeting both market requirements and customers’ expectations. Our products enjoy an excellent reputation and have been exported to Europe, South-America, the Middle-East, Southeast-Asia, Africa and Russia etc.. We sincerely hope to establish good and long-term business relationship with your esteemed company.

Images:

FAQ

1.What's your MOQ?

50MT, it is for one container.

2.Whether your company have QC teams?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.

3. What's your normal delivery time?

Our delivery time about 10-20days for standard sizes, if you have other requirements like hardness and width ,it is about 20-40days. But don't worry ,we also try our best for the

- Q:How are steel coils processed for cutting to length or blanking?

- Steel coils are typically processed for cutting to length or blanking through a series of steps. First, the coils are unwound using a machine called an uncoiler, which feeds the steel into the cutting process. Then, the steel passes through a leveler to ensure a flat surface. Next, it enters a shear or blanking process, where the steel is cut into desired lengths or shapes. Finally, the cut pieces are stacked or packaged for further use or distribution.

- Q:What are the different types of steel coil coatings?

- There are several different types of steel coil coatings that are used for various purposes. Some of the most common types include: 1. Galvanized Coating: This is a zinc-based coating that provides excellent corrosion resistance to steel coils. It is often used in outdoor applications where the coils are exposed to harsh weather conditions. 2. Galvannealed Coating: Similar to galvanized coating, galvannealed coating also contains zinc, but it is heat-treated to form an alloy with the steel surface. This type of coating provides better paint adhesion and is often used in applications where the coated coils will be painted or further processed. 3. Pre-painted Coating: As the name suggests, pre-painted coatings are applied to steel coils before they are delivered to customers. These coatings can be made of various materials, including polyester, polyurethane, epoxy, or fluoropolymer. Pre-painted coils are commonly used in construction, automotive, and appliance industries. 4. Electro-galvanized Coating: This coating is applied to steel coils through an electroplating process, where a thin layer of zinc is deposited on the surface of the steel. Electro-galvanized coatings provide good corrosion resistance and are often used in indoor applications or where a thinner coating is desired. 5. Aluminized Coating: Aluminized coatings are made by applying a thin layer of aluminum to the surface of steel coils. This type of coating provides excellent heat resistance and is commonly used in exhaust systems, ovens, and other high-temperature applications. 6. Organic Coatings: Organic coatings are typically applied to steel coils to provide additional protection against corrosion and improve aesthetics. These coatings can be in the form of paints, lacquers, or powder coatings, and they can be customized to meet specific requirements in terms of color, gloss, and durability. Overall, the choice of steel coil coating depends on the specific application, environmental conditions, desired aesthetics, and performance requirements.

- Q:How do steel coils contribute to the manufacturing of agricultural machinery?

- Steel coils are used in the manufacturing of agricultural machinery as they provide the necessary strength and durability required for heavy-duty equipment. These coils are often used to fabricate components such as frames, chassis, and structural supports, ensuring stability and reliability of the machinery. Additionally, steel coils can be easily shaped and welded, allowing for customization and versatility in design, ultimately contributing to the overall efficiency and functionality of agricultural machinery.

- Q:How are steel coils used in the agricultural sector?

- Steel coils are used in the agricultural sector for various purposes such as manufacturing machinery, constructing storage facilities, and creating equipment like irrigation systems and grain bins. They provide strength, durability, and flexibility to support the demanding needs of the agriculture industry.

- Q:What are the various surface finishes available for steel coils?

- Steel coils offer a range of surface finishes, each with its own properties and uses. Some commonly used finishes include: 1. Hot rolled: Steel is rolled at high temperatures, resulting in a rough surface. This finish is great for structural applications like construction materials and industrial machinery. 2. Cold rolled: Steel is rolled at room temperature, creating a smoother surface. It is commonly used in automotive and appliance manufacturing due to its superior finish and accuracy. 3. Galvanized: Steel is coated with zinc to protect against corrosion. Galvanized coils have a shiny appearance and are suitable for outdoor applications such as roofing and fences. 4. Electro-galvanized: Coated with a thinner layer of zinc through an electroplating process, these coils offer good corrosion resistance. They are commonly used in electrical appliances, automotive parts, and construction. 5. Pre-painted: Coated with paint or polymer film, pre-painted coils provide both corrosion protection and aesthetic appeal. They are extensively used in construction for roofing, cladding, and wall panels. 6. Stainless steel: Stainless steel coils have unique properties, including corrosion resistance, heat resistance, and chemical damage resistance. They are ideal for industries like food processing, medical equipment, and marine applications. These examples showcase the variety of surface finishes available for steel coils. The choice of finish depends on factors such as the intended use, desired appearance, and level of corrosion resistance required.

- Q:How are steel coils used in the production of electrical appliances?

- Steel coils are used in the production of electrical appliances as the core material for transformers and motors. The coils are wound around an iron core to create electromagnetic fields that enable efficient energy transfer and power generation within these appliances.

- Q:How are steel coils used in the production of HVAC ductwork?

- Steel coils are used in the production of HVAC ductwork as they are rolled into thin sheets and then formed into the desired shape to create the ducts. The coils provide strength and durability to the ductwork, ensuring it can withstand the high temperatures and pressure of air conditioning and heating systems.

- Q:How can I arbitrate quality of steel before purchasing it??

- The quality of the alloy can be very well be judged by its appearance and lustrous surface. The more luster on the surface the more refine will the steel be. To judge its tenacity and endurance, the alloy can be subjected to a series of procedures involving stress and shock. The reaction to these processes can determine whether the steel be fit for the purpose required.

- Q:How are steel coils used in the manufacturing of agricultural implements?

- Steel coils are used in the manufacturing of agricultural implements by being shaped and formed into various components such as blades, tines, and frames. These components are then assembled or attached to the implements, such as plows, harrows, and cultivators, to enhance their durability, strength, and performance in agricultural activities.

- Q:Can steel coils be used in outdoor applications?

- Indeed, outdoor applications can make use of steel coils. Steel, recognized for its resilience and robustness, proves to be ideal for various outdoor purposes. Commonly utilized in construction, automotive manufacturing, and transportation industries, steel coils exhibit resistance against adverse weather conditions like rain, snow, and UV exposure. Furthermore, to enhance their durability and prolong their lifespan, steel coils frequently undergo protective finishes such as galvanized or painted coatings. Ultimately, owing to their strength, durability, and ability to withstand environmental factors, steel coils emerge as a dependable and versatile choice for outdoor applications.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Rolled Steel Coil / Sheet / Plate SPCC in CNBM from China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords