Refractory Material Melt Extracted Stainless Steel Fiber

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Place of Origin: China

Model Number: 304,310,430,446

Material: Stainless Steel, Stainless Steel

Feature: High quality grade

Standard: ASTM A820

Types: Melt Extracted

Length: 25mm/35mm/19mm

Diameter: 0.3mm-0.7mm

Melting Point: Greater than 1500C

Application: Refractory Industry

Package: In cartons then put into pallets.

Production process:

Quality assurance:

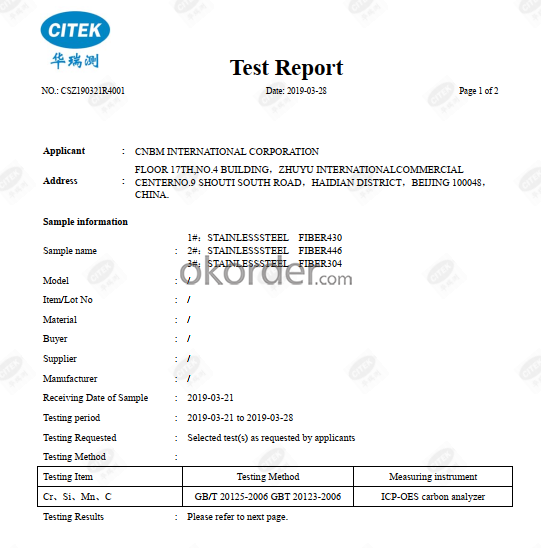

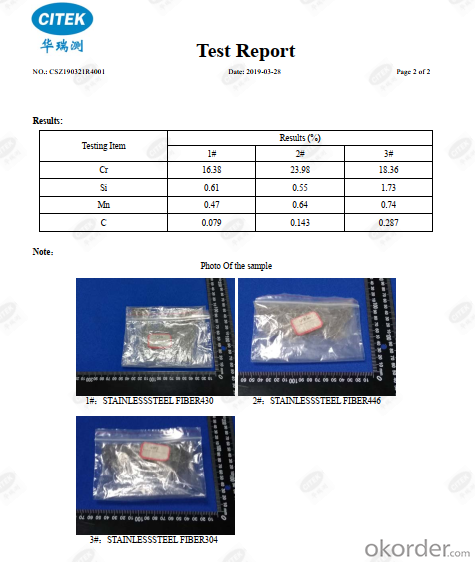

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

FAQ:

Q: What kind of payments does your support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer.

Q: Do you have other products?

A: Yes, please check the pictures:

Test Report:

- Q:I wanna ask about the thermal insulation material fire resistant level?

- The inorganic glass wool, rock wool and foam glass. Organic: The best is the phenolic foam, phenolic foam composite cement layer is level A.

- Q:What kind of refractory materials can withstand 1500℃ when processing briquette stove core and meanwhile cost less?

- The main material is quartz sand and it is the cheapest, and can resist 1500℃ without any difficulty.

- Q:What are the structural properties of refractory materials provided by the manufacturer of the refractories include?

- For high efficiency continuous casting, molten steel will cause turbulence in tundish because of its fast casting speed. The sharp turbulence, on the one hand, breaks through the slag layer, involves the slag in the molten steel, and exposes the liquid steel to the air. It is oxidized two times;

- Q:what are the types of piping insulation material fire?rating?

- Pipe insulation material Fire rating: heat conductivity coefficient(at room temperature) 0.025 grade non-combustible Class A low temperature bending ≤ 5000 breaking elongation 5,000 specifications 5000 anti-bending?strength 5000 compressive?strength 5000 special brand of high use temperature -250 ~ 150 ℃ core material, phenolic foam, form, stratiform, shape,flake.

- Q:Who knows the external wall thermal insulation materials fire rating requirements?

- The requirements of Department of Housing and the Ministry of Public Security No. 46: Residential buildings: the height of building is greater than 100 meters, the combustion performance of insulation materials should be level A. The other civil buildings: 24≤ height

- Q:What type of firebrick does TZ-3 represent?

- Z represents a straight brick, T stands for common brick, common straight standard brick, -3 represents the length, and the specification is 230 * 114 * 65 (mm).

- Q:How to divide the fire resistant level of construction thermal insulation materials?

- 1, Combustion performance of the national standard building materials are divided into the following levels: Class A: incombustible building material: Material that almost never burn. Class B1: nonflammable building material: Nonflammable materials have good effect of flame resistance. In case of fire it in the air or at high temperature it is difficult to catch fire and spread, and when the fire source is removed, the combustion can stop immediately. Class B2: combustible?building?material: Combustible materials have good effect of flame resistance. In case of open fire in the air or at high temperature, it will immediately burst into flames and spread the fire quickly, such as wooden column, timber roof truss, wooden stairs, etc. Class B3: flammable building material: No flame-retardant effect, highly flammable, high risk of fire. 2, According to fire?rating, external wall thermal insulation materials can be divided into 1) thermal insulation material with class A combustion performance. Rock wool, glass wool, foam glass, foamed ceramics, foam cement, hole-closed perlite,etc. 2) thermal insulation material with class B1 combustion performance: Extruded polystyrene board (XPS) after special treatment /polyurethane (PU) after special treatment , phenolic aldehyde, gelatine powder polyphenyl granule, etc. 3) thermal insulation material with class B2 combustion performance: Molding polystyrene board (EPS), extruded polystyrene board (XPS), polyurethane (PU), polyethylene (PE), etc.

- Q:Who knows the new fireproof and thermal inuslation matertial?

- Ceramic foam insulation board, XTP vacuum insulation panels and a variety of composite insulation panels, etc. Relatively speaking, the inorganic insulation board is a trend. In terms of the overall performance, the cost performance of the foam insulation board is higher. XTP has the best performance, but with a little trouble in construction. Because of the vacuum characteristics, transportation and installation process should be very careful.

- Q:Who knows the texture of fire-proof wooden door material?

- Steel door, wooden door or steel wooden door can be inset fireproof laminboard, such as rock wool, perlite. Perlite (fireproof doors filling material, fireproof doors raw material) using for fireproof door core is mainly used for the filling material of fireproof doors and security doors. Fire protection, thermal insulation, good sound insulation effects, and higher performance than aluminum?silicate?wool and rock wool. The combustion performance of perlite using for fireproof door core reaches class A non-combustion, which is new type of fireproof doors filling material with characteristics of low cost, good fireproof performance and excellent environmental protection performance. The advantages of fireproof door core perlite as fireproof door filling material: 1, Good fireproof performance, so it has a function of fire prevention. Environmental protection: all materials are environmentally friendly products. Pollution-free: the product is composed of glass fiber reinforced materials and inorganic binder. 2, with characteristics of non-flammable, non-explosive, water-resistant, oil-resistant, chemical erosion resistant, non-toxic and good mechanical strength, etc. The product can be used for mechanic processing like sawing, drilling, gouging, etc. High fire resistance, in the simulated combustion tests, it doesn't deform when the flame temperature reaching 800 degrees, has good fire retardant and fire-resistant properties. 3, product material is cheap, suitable for all kinds of fireproof materials. Perlite fireproof board is made by pressing the expanded perlite powder and high temperature fireproof adhesive through mould, suitable for the filling material of fireproof wooden door and fireproof steel door, which is the substitute products of aluminum?silicate?wool and rock wool. 4, has advantages of light volume-weight, high refractoriness, strong compressive strength, small thermal conductivity, non-flammable, non-toxic, tasteless, non-pollution, etc.

- Q:What are the components of refractory clay?

- The major raw material are bauxite, magnesite, silica, etc. It is easy to combine, high temperature resistant, corrosion resistant and has other advantages. It can be applied for refractory bricks in a variety of masonry.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Refractory Material Melt Extracted Stainless Steel Fiber

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords