PVC Panel Hot Selling PVC Wooden Design

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 550000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PVC Panel Hot Selling PVC Wooden Design

We have specialized in PVC panel for many years. And 80% output of our PVC panel is export to oversea market.

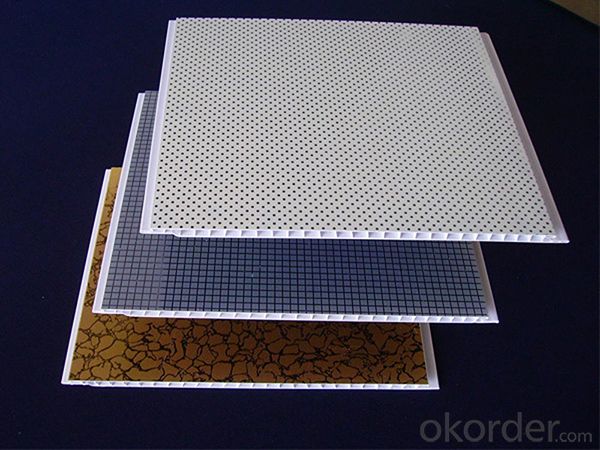

Usual Specification:

Length:5.98m,5.95m,5m or customized

Width:30cm,25cm,20cm, 19.5 cm, 19 cm, 12 cm or customized

Thickness:1.2cm, 1.1cm, 1.0cm, 0.9cm,0.85cm,0.8cm,075cm,0.70cm,0.6cm,0.5cm or customized

Color: According to the customers’ requirements

Pattern: Modern design

Surface: common glossy, high glossy, printing, transfer printing(hot staming), laminated printing

The feature:

1)The variety of colors and patterns

2)High intensity, resist erosion, anti aging

3)Fireproof, waterproof, environment friendly

4)Waterproof and heatproof

Applications:

Household Ornament: Wall and ceiling of indent independent house bathroom

Public and Management Place: Toilet of building and hall, bathroom and kitchen

Usual Packing: 10pcs/shrink wrapping or carton

Main market: South America, Eastern Europe, Southeast Asia, Eastern Asia, Africa, Oceania and Mid East.

FAQ

1. Is OEM available?

Re: Yes, OEM service is available.

2. Are you factory?

Re: Yes. we are the largest factory in China.

3. Can we get sample?

Re: Yes, sample is free for our customer.

4. How many days for production

Re: usually 2 weeks after receiving of downpayment

Pictures

- Q:PVC foam board with formaldehyde?

- There is, but the concentration is not very high, there is no smell.

- Q:PVC board inkjet and PVC board photo which effect is good

- The accuracy of inkjet is generally not high, not seen directly to the inkjet sprayed on the PVC, because PVC itself is more expensive material, rough picture is violent heaven and earth. The general accuracy of the photo is better, but generally are adhesive glue stick to the PVC there is a flat printing, this effect is the best, the most clear, but the price is the highest.

- Q:Pvc wall board heat will produce toxic gas do

- Some, PVC chemical name is PVC, chlorine itself is toxic, in the high temperature when there will be stimulating gas emitted, the general temperature is above 100 degrees will have a clear smell, low temperature (no more than 60 Degrees Celsius) is very slight, little impact

- Q:Finished pvc board how to install the kitchen led lights

- Open a hole, then a good line, fitted with lights, card buckle. Installed.

- Q:Ring thickness of 5-10mm, diameter 250mm, diameter 150mm, PVC board raw material is 1 meter by 2 meters. Products to mass production, would like to ask what kind of equipment can be directly on the shelf 1 meter by 2 meters on the plate to cut products? I find someone else manufacturers out of a sample, but I do not know what they are using the machine, only know that carved machine.

- Engraving machine can, CNC milling machine can. However, this method of cutting with the tool will consume more material. Can also use laser cutting machine, or water cutting machine, can also be directly cut into a ring, and the incision is very narrow, almost no loss of material. In addition, if the thickness of the plate to take the lower limit, such as 5 mm. If the processing of a large number, you can consider a pair of punching die, directly punch out. Fast, provincial materials, and low cost

- Q:Pvc board and rubber contact why fade?

- Production of PVC sheet on the use of toxic compound lead salt more stable, more cost-effective Baohua PVC efficient heat stabilizer patent series

- Q:What is the difference between oak bathroom cabinet and PVC bathroom cabinet?

- Oak has a solid wood texture, the use of waterproof and environmentally friendly paint spray treatment, compared to other man-made sheet, lower formaldehyde emission, natural environmental protection, but also more durable. Advantages: health and environmental protection, natural honest, high-grade elegant. Disadvantages: expensive. The PVC is a plastic bathroom cabinet, mainly to PVC as a plastic panel, after vacuum pressure adsorption in the MDF or moisture board, moisture board for wood pulp with moisture-proof particles of curing products, generally blue or green, Blister can be drawn after the board as a whole, without edge, with excellent moisture-proof waterproof performance. Advantages: rich colors, high temperature, anti-carved, easy to clean up. Disadvantages: resistance to chemical corrosion is not high. ???? Oak has red oak and white oak, usually Mito imported. There is a domestic called oak, and oak with the Branch, similar texture

- Q:My home PVC board is always issued a flap sound, how is it? (My family is not the top floor)

- The ceiling of the plate that may be caused by the deformation of the keel need to open to see the corporal is not a keel deformation go

- Q:The head that links into the tub broke off when i was tightening it and i turned the nob so water shouldn't run but its still leaking. My repair guy can't make it for a few days. Its leaking on the rug and going through the ceiling to the first floor!!! I tried to duct taping it but no matter how much i use it still leaks through the cracks after minutes. I need a cheap quick fix till the repairman comes.

- You need to try to be more specific. Is this a drain or water line feeding the tub?

- Q:Our company in the PVC board on the performance of follow-up table, every day in the top with a black whiteboard pen to fill, but the traces of how rub are not clean ah, I would like to ask what magic method can be black white board pen wipe clean? thank you very much!

- Use a soft cloth or sponge, dip with alcohol to wipe

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PVC Panel Hot Selling PVC Wooden Design

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 550000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords