Prime cold rolled steel coils shipping from china

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 56437 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Cold Rolled Steel coil is a mill product made with a high degree of gauge accuracy and uniformity of physical characteristics.

The smooth deoxidized matte finish gives an excellent base for paint, lacquer and enamel. Box annealing and absence of scale permit stamping and moderate drawing operations. Sheets bend flat on themselves without cracking. Oiling protects Surface

against rust. The application of surface oil to cold rolled steel coil/sheet is intended to provide protection from corrosion ("rusting") during shipment and warehousing..

It is suited to formation by bending or drawing, which enables complex parts to be produced in good repeatable conditions

and intended for indoor use.

These cold rolled steel coil/sheet grades have excellent formability, which facilitates cold forming operations, and are ideal

for deep drawing. Our range of steels for cold forming offer excellent forming performance, due to the low scattering of their

chemical composition and their mechanical properties, which guarantees processing consistency.

Standard and Grade :

Cold rolled steel coils | ||||

JIS G3141-2005 | EN10130-2006 | ASTM A1008-12a | ||

Commercial quality | SPCC | DC01 | CS Type A/B/C | |

Drawing quality | SPCD | DC03 | DS Type A/B | |

Deep drawing quality | SPCE SPCF(non aging) | DC04 | DDS | |

Extra deep drawing quality | SPCG(non aging) | DC05/06 | EDDS | |

Application :

Automobile Industry, White Goods, Home Applicances, Oil & Air filters, semi product for coating with enamel or zinc, construction &

building sector, air-conditioning, furniture, radiators, tubes, profiles, mechanical construction, shelving, containers, drums

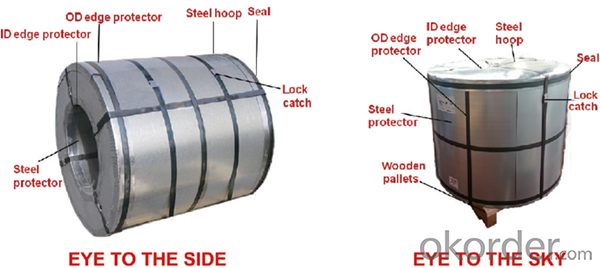

Packing:

Packaging Detail | The packing of coil consists of anti-damp paper ,PVC film ,hardboard paper , steel box , strapped with steel strips, fitted with locks and edge protectors and guarantees the optimal condition of the delivered goods. Each coil can be additionally fitted with wooden/steel skids(eye of the side) or wooden pallets(eye of the sky) |

Delivery Time | within 30 days of receipt of LC original or prepayment |

Our Services:

MOQ | FCL, 25 metric tons per 20GP, can be assorted with different sizes. |

LCL for trial order is acceptable. | |

Price Term | EX-WORK, FOB China Port, CNF, CIF |

Payment | T/T, 30% advanced payment before production and balance before shipment; OR Irrevocable L/C at sight. |

Delivery Time | within 30 days of receipt of LC original or prepayment |

FAQ:

1. Can you offer OEM to me? What about MOQ?

Of course, we are a professional with OEM manufacturer for 9 years. the MOQ can be 50 ton/ order.

2. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we

have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as

soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

4.How Can I Get Some Sample?

We are honored to offer you free sample, but courier charges will be on your side.

- Q:How are steel coils used in the manufacturing of industrial filters?

- Steel coils are used in the manufacturing of industrial filters as a primary material for constructing the filter frames and support structures. The coils are typically cut, shaped, and welded to create the necessary framework that holds the filter media and allows for efficient filtration. The strength and durability of steel make it an ideal choice for withstanding the pressure and demands of industrial filtration processes.

- Q:help me and my twin love this cutie in our form !? how do we steel hime from bitchey rebecca!? X X X xX

- Please...for the sake of everyone else...grow up and learn how to spell!! The boy you and your twin likes is taken, and you should seriously keep your hands off another girl's boyfriend. Even if you steal him, you'll be fighting over him with your twin. Not worth it. Karma is going to come all the way back around, and kick you hard on the butt and slap you on the face, so you better watch out.

- Q:I am in the market for a good hunting knife under $100. I am primarily looking for a knife that will keep it's edge. What type of steel should I be looking for?

- Don't know much about steels, but apparently SV30 is the toughest son of ore you can look for, and it's so tough I've heard of knife makers rejecting it for softer steel. Look for Gerber and Buck for low end SV30 knives under $100.

- Q:What are the common thicknesses available for steel coils?

- The specific requirements and applications determine the available common thicknesses for steel coils. However, various industries commonly produce and use certain standard thicknesses. Typically, steel coils can range in thickness from 0.005 inches to 0.5 inches or more, depending on the type of steel and its intended use. For instance, in automotive manufacturing, where steel coils are utilized for body panels and structural components, the thicknesses commonly range from 0.5 mm (0.020 inches) to 3 mm (0.118 inches). In the construction industry, steel coils are employed for roofing, siding, and structural framing. The common thicknesses can vary from 0.014 inches to 0.062 inches, depending on the specific application and structural requirements. Similarly, appliances manufacturing, such as refrigerators, washing machines, or HVAC systems, frequently employ steel coils with thicknesses ranging from 0.018 inches to 0.035 inches. It is important to note that these are only a few examples of common thicknesses, and variations can occur based on the specific requirements of different industries and applications. Custom thicknesses can also be produced upon request to meet unique needs in various sectors.

- Q:How can the quality of steel coils be ensured?

- The quality of steel coils can be ensured through a combination of rigorous testing, adherence to industry standards, and effective quality control measures throughout the manufacturing process. This includes conducting various tests such as chemical composition analysis, mechanical property testing, and surface inspection to verify the integrity and durability of the steel coils. Additionally, implementing strict quality control protocols, regular inspections, and continuous improvement initiatives are essential to ensure consistent and high-quality production of steel coils.

- Q:Can steel coils be deep-drawn?

- Yes, steel coils can be deep-drawn. Deep drawing is a metal forming process where a sheet metal blank is drawn into a die cavity to create a desired shape. Steel coils, which are flat strips of steel, can be fed into a deep drawing machine and formed into various complex shapes through this process.

- Q:What are the factors that affect the price of steel coils?

- There are several factors that influence the price of steel coils. Firstly, the cost of raw materials such as iron ore and coal, which are essential for steel production, can significantly impact the price. Additionally, the demand and supply dynamics of steel in the market play a crucial role. Factors like economic growth, construction activity, and infrastructure development can drive up the demand for steel, leading to price increases. On the other hand, if there is excess supply or reduced demand, prices may decrease. Moreover, fluctuations in energy costs, transportation expenses, and currency exchange rates can also affect the final price of steel coils.

- Q:How are steel coils used in the manufacturing of springs?

- Steel coils are used in the manufacturing of springs by being compressed or wound into a helical shape, which provides the necessary flexibility and resistance to support various applications.

- Q:How are steel coils tested for compliance with industry standards?

- Steel coils are tested for compliance with industry standards through various methods. These include visual inspection, dimensional measurements, and mechanical tests such as tensile and impact tests. Additionally, chemical composition analysis is performed to ensure that the steel meets the required specifications. These comprehensive tests ensure that the steel coils are of high quality and meet the standards set by the industry.

- Q:How are steel coils processed for edge trimming or slitting during processing?

- Steel coils are processed for edge trimming or slitting during processing by using specialized machinery. The coils are uncoiled and fed through a slitting machine, which cuts the coil into narrower strips. These strips are then passed through an edge trimming machine, which removes any irregularities or excess material from the edges. This process helps to ensure that the steel coils meet the desired specifications and are ready for further processing or use in various industries.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Prime cold rolled steel coils shipping from china

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 56437 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords