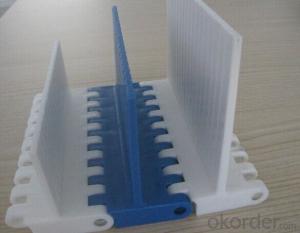

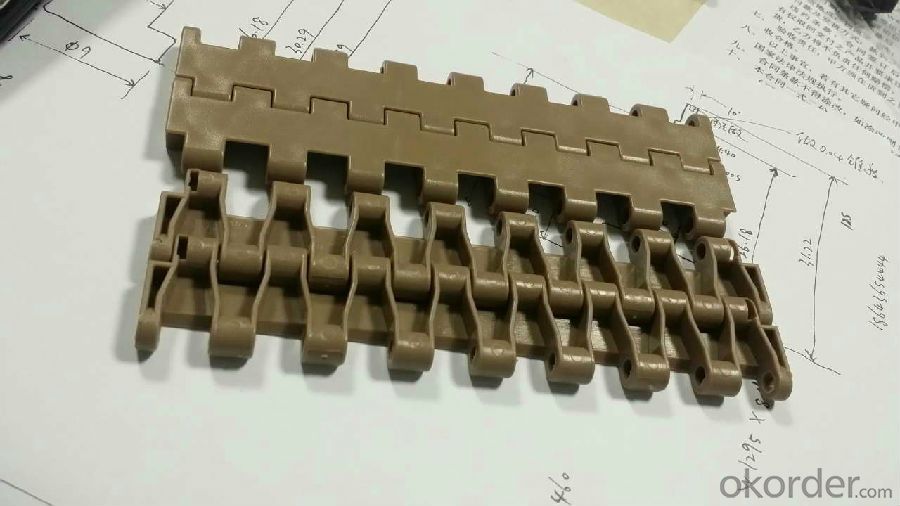

PP/POM Plastic Modular Chain Conveyor Belt

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PP/POM Plastic Modular Chain Conveyor Belt

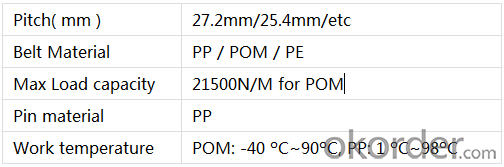

Specification of modular belt

Product Features :

Good performance of anti-stretching, anti-impact, anti-creepage, anti-abrasion, anti-erosion.

Excellent mechanical performance.

Stable chemical property.

Wide range of work temperature.

Low friction on bottom side.

Non-stick of water and oil.

Long service life.

Application of our products:

Our products are widely used in the conveyor of production of light industry as below:

Agriculture: Washing/disinfecting/drying/packing/cooling/freezing of vegetables/

fruit/meat/aquatic products/sea food.

Food: Instant noodles/rice noodles/snacks/box lunch/bakeries/cans/sugar.

Wines and beverage: Mineral water/pure water/soft drink / milk/dairy/wines.

Medicine and chemical industry.

Tobaccos.

Electronics and batteries.

Machinery components/auto parts/powder metallurgy/glass.

Logistics.

Pls contact me freely if any inquiry,thank you!

- Q:Do all plastics have plasticizers?

- Plasticizer is divided into toxic and non-toxic, relieved, and now the plastic basically useless toxic plasticizers, and generally do not contain phthalate two formic acid

- Q:Do olive nets affect the water and nutrient uptake of olive trees?

- Yes, olive nets can affect the water and nutrient uptake of olive trees. The nets create a physical barrier that can limit the amount of water and nutrients reaching the tree's roots. Additionally, the nets can reduce sunlight exposure, which is essential for photosynthesis and nutrient absorption. Therefore, careful consideration should be given to the installation and maintenance of olive nets to ensure the tree's water and nutrient needs are met.

- Q:Do olive nets also protect against other pests?

- No, olive nets are primarily designed to protect olive trees from birds and other avian pests. They may not be effective against other types of pests such as insects or rodents.

- Q:The plastic basin is broken. How do you fix it?

- Generally bad, throw it, but there is a glue stick can be glued to the plastic, burn it with a stick, you can

- Q:Are olive nets resistant to mold or mildew?

- Yes, olive nets are generally resistant to mold or mildew due to their durable and breathable materials.

- Q:Why plastic is not environmentally friendly?

- Due to the inability of plastics to degrade naturally, it has become the number one enemy of mankind, and has also led to the tragedy of many animal deaths. For example, the monkeys in the zoo, pelicans, dolphins and other animal, are readily lost visitors swallowed 1 plastic bottles, and finally as indigestion and painful death; looked beautiful and pure sea, approaching the look, in fact, filled with various kinds of unable to accommodate the oceans of plastic waste, in more than one die seabirds sample intestines, found all kinds of plastic can not be digested.

- Q:How do olive nets prevent olives from being damaged by frost?

- Olive nets prevent olives from being damaged by frost by acting as a protective barrier. These nets are placed over the olive trees to shield them from direct contact with the freezing air. The nets trap a layer of air between the olives and the outside environment, creating a microclimate that is slightly warmer and less prone to frost damage. This insulation helps to prevent freezing temperatures from reaching the olives, preserving their quality and preventing frost-induced injuries.

- Q:Can olive nets be used for olive trees in regions with limited labor availability?

- Yes, olive nets can be used for olive trees in regions with limited labor availability. Olive nets are designed to catch the olives as they fall from the trees during harvesting. By using these nets, the need for manual labor to pick the olives from the ground is significantly reduced. This makes it a practical solution for regions facing a shortage of labor. Additionally, olive nets help protect the fallen olives from being damaged and keep them clean, ensuring higher quality harvests.

- Q:Do olive nets affect the growth of the olive trees?

- Yes, olive nets can affect the growth of olive trees. While they serve as a protective measure against pests and birds that may damage the fruit, they can also limit sunlight exposure and air circulation, which are vital for the healthy growth of olive trees. Therefore, careful consideration should be given to the duration and timing of net usage to minimize any potential negative effects on tree growth.

- Q:Can olive nets be used in combination with frost protection methods?

- Yes, olive nets can be used in combination with frost protection methods. Olive nets are primarily used to protect olives from birds and other pests, but they can also provide some level of frost protection by acting as a physical barrier that reduces the exposure of olive trees to cold temperatures. However, for effective frost protection, additional methods such as heaters, wind machines, or sprinkler systems may need to be employed in conjunction with the olive nets.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PP/POM Plastic Modular Chain Conveyor Belt

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords