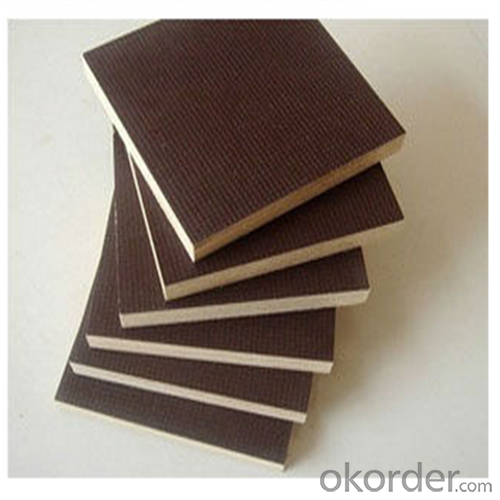

Poplar and Combi Material Film Faced Plywood

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 8000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description:

Place of origin: Shandong China

Face&back: Okoume, Bintangor, Pencil Cedar, Keruing, Poplar, Birch, Pine, Maple, Hardwood, Ash, Oak and as your requested

Core: Poplar, Hardwood, Hardwood, Combi, Birch, eucalypts, as your requirement.

Size: 1220*2440/1250*2500mm and as your requirement

Thickness: 2mm to 30mm and as for your requirement

1/8 inch(2.7-3.6mm)

1/4 inch(6-6.5mm)

1/2 inch(12-12.7mm)

5/8 inch(15-16mm)

3/4 inch(18-19mm)

Thickness tolerance: 2-6mm: +/-0.2mm; 6-30mm: +/-0.3mm

Grade: BB/BB, BB/CC, CC/CC, CC/DD,DD/EE, etc.

Glue: MR,E1,E2,Melamine,WBP Phenolic

Moisture: 10%-15%

Joint way: Overlap joint, end joint, scraf joint, finger joint

Strength: High bending strength Strong nail holding

Quantity: 8 pallets/20ft,16 pallets/40ft,18 pallets/40HQ

Usage: construction, Furniture, decoration, packing.

Certificate: ISO9001: 2000; CE; CARB

Main market: Middle East, South Asia, South America, Africa

Shipment & payment:

MOQ: One container

Port: Qingdao Port, China

Packing details:

Inner packing: 0.2mm thick plastic bag

Outer packing: pallets covered with plywood/carton, then steel taped for strength

Delivery time: 2 weeks after your deposit

Payment: T/T, 30% deposit, the balance against the copy of B/L, L/C at sight.

Advantage:

Capacity: 6000 CBM per month

Can supply samples

High quality and competitive price

Over 30 years’ experiences in export

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q4: If we can produce some wood products according to customers request?

A4: Yes, we can produce wood products according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, if needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

Product Show:

- Q:100 thick roof color steel foam sandwich panels how to calculate the weight

- You calculate 1 square meters wide inside and outside the two thin steel plate added to the foam core weight, the number multiplied by 10, is the bulk density, its unit is ㎏ / m?. Or, weigh each block to remove each area, then multiplied by 10, is the bulk density.

- Q:What are the types of metal wool wool sandwich panels?

- There are two types of continuous production and intermittent production, the former mainly produces large quantities of industrial sheet, the process requirements and smoothness and beauty is not very high industrial plant. Intermittent production is less than continuous, but the plate process up to a high level, to produce a beautiful and smooth sheet of outstanding performance

- Q:How to use the sandwich board to the concrete square column into a cylindrical and finishes are made of aluminum-plastic package, it is best to have pictures or drawings

- With a sandwich made of a semi-circular in the bottom of the column, the top and the middle of every 500 or so, with expansion bolts wooden side of the board will be fixed on the column, with a sandwich panel saw a narrow wood, Into a round wooden column of the pillars, and then stick to the aluminum plate.

- Q:So here's the deal, I really need to run the oven cleaner, and I know how much smoke will come out of the oven, and I have a wired smoke alarm directly above the stove (landlord's design not mine). If I cover it with a sandwich bag, will that slow down the chance of it going off or increase the chance? Yes I know to remove the bag directly after the oven cleaner is done for obvious saftey reasons.

- it should slow it down

- Q:I would like to build factories. Would like to ask the thickness of 10 cm under the foam sandwich board how much money a square.

- Only know the current price of foam board is 70 yuan a cubic (the lightest material), if coupled with the price of color steel, it is estimated that a flat price is more than ten dollars it Of course, the best choice of flame retardant, it should be more than 20 square.

- Q:Hard polyurethane sandwich board combustion performance?

- In general, the ordinary hard polyurethane sandwich board combustion performance is very good, it depends on how you treat this problem. Requirements are high or low are the main reasons for quality

- Q:Can the color steel sandwich panel be hit on a stainless steel tube?

- Playing is able to hit. But we have never done so, stainless steel too no thickness, eat nails is not strong, no effect. So do not agree with stainless steel.

- Q:Glass wool cotton color steel composite panels, also known as sandwich panels should be how to do re-test? Is it good to do it?

- Do the bare board re-test or do complex panel to see your design requirements and product record is how to prepare. Sometimes it is compound re-examination

- Q:Color steel 50 mm rock wool sandwich board one meter how much the price

- It is not normal to say that there is a flat between 40 and 50

- Q:Because it was not promptly cleared, after the wind and sun, it is difficult to clear, because the area is relatively large, a little bit of clean up by hand very difficult, which experts have any good way not?

- 2. Board protection form: complex PVC protective film 【Features】 1. Advantages: good fire resistance, sound insulation better. Yanmian Caigang sandwich panel Features: Caigang rock wool composite board products for the A-class fire board 1. Good fire performance:

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Poplar and Combi Material Film Faced Plywood

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 8000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords