Polyethylene Blown Film Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specifications

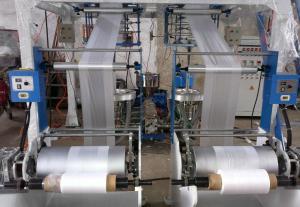

Polyethylene Blown Film Machine/Mini film blowing machine

2. Material : LDPE

3. Output: 80kg/h

4. Film Width:800~1200mm

Polyethylene Blown Film Machine

The machine is used to blowing PE film.

EX-40:

L:D=30:1

OUTPUT:35 KG/H

FILM WIDTH:200--400

EX-65:

L:D=30:1

OUTPUT:80KG/H

FILM WIDTH:800--1200

- Q:Operation description of turbine oil vacuum oil filter?

- Because it is located in a position similar to that of the steam seal, it is easy to enter steam (steam condenses into water in the oil). Cause there is middle water cut,

- Q:Common troubles of vacuum oil filter

- Failure cause, elimination method, vacuum degree can not be reachedTechnical standard 1, filtered oil contains more water, vacuum pump exhaust gas, excessive steam;2, due to the use of altitude, not in the standard atmospheric pressure, the impact of changes in vacuum;3 、 vacuum oil low oil level line in vacuum pump;

- Q:Under what conditions does the air pressure oil filter fail to clean oil?

- How do you say this? For example, the filter element, the filter element is used, right?

- Q:How is the plate type oil filter put into operation?

- Plate and frame oil filter is not very expensive, generally used, in the past between 5000, 10 thousand, 5000, you dare to buy, then I can not! A penny a penny, the price is so high, the frame filter oil machine profit is so low, don't be too demanding, otherwise, can't buy good goods! There is a manufacturer's plate is very good: Chongqing million U. S. electrical and mechanical plate and frame, our company every year as they supply about one hundred thousand of the filter paper and millions of filter elements, their oil filter is very good.

- Q:What's the function of a centrifugal oil filter?

- Centrifugal oil filters use their high-speed centrifugal force from the heart (centrifuge) to make the oil, water, and impurities of different lubricating oils separated by different centrifugal forces

- Q:Classification of oil filters According to the principle of the oil filter

- Three, reducing oil color, regeneration of oil filter. Such as vibration, slag discharge, decolorization, oil filter, automatic slag filter and so on.Four, including the above functions, filtered products by the national new oil standard (GB) qualified oil filter. For example, ZTS integrated purifier.Scope of applicationMainly applicable to mines, metallurgy, petroleum, rail, machinery, chemicals, textiles, cement, power plants, meters and other departments. The purification and regeneration of various industrial lubricating oils play a great role in the deterioration of pollution, prolong the overhaul cycle and service life of the equipment, and reduce production costs. It can effectively remove pollutants in oil, such as water, water soluble acid, alkali, mechanical impurities, etc., so as to improve the kinematic viscosity, flash point and emulsifying property of oil products. To quickly restore the oil to the required performance, close to or meet the corresponding national standards for new oil.

- Q:Characteristics of vacuum oil filter

- Vacuum oil filter, also called vacuum oil filter, oil filter, vacuum oil purifier which has the characteristics of small volume, light weight, easy to move, the proportion of low noise, long continuous operation, stable performance, convenient operation etc.. Is the ideal equipment for the power plant, power plant, substation and electric appliance manufacturing plant, refinery, petrochemical and other industrial and mining enterprises and filtration of transformer oil, turbine oil, hydraulic oil, 40# oil in water, gas and impurity particles

- Q:How to choose the proper plate and frame pressure filter

- Plate and frame pressure type oil filter is usually thousands of dollars, the size of the model may be tens of thousands, the size of the model according to the filter needs to determine. The bigger the oil pump, filter plate, filter paper area and so on, the higher the price.

- Q:Transformer oil filter can be rented there

- Rent used machinery, may go to your local mechanical and electrical market, the secondary market, ask, perhaps there will be information. In addition the use of transformer oil filter is generally the power company substation, power transmission engineering, power plant, transformer production enterprises, in addition to large industrial and mining enterprises have owned power plant will be used, the precision industry slightly.

- Q:How to use the centrifugal oil filter properly?

- 5) the user should mainly consider the establishment of reserved operating space, and the surrounding building spacing of not less than 1 meters, there is no lifting device on the centrifuge, easy to maintain the fashion centrifuge.3 preparation before starting1) the lubrication of each lubrication position shall meet the requirements, and the grease or oil in the bearings shall be filled with no leakage.2) check whether the feed pipe is firm and correct.3) all connection bolts shall be fastened and the belt tensioning should be moderate.4) point motor, check whether the turn of the source motor is consistent with the required direction (from the end of the liquid outlet, the drum should be clockwise rotation); whether there is abnormal friction arising from abnormal sound.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Polyethylene Blown Film Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords