polyester non woven fabric,breathable nonwoven fabric, hydrophobic nonwoven fabric

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 roll

- Supply Capability:

- 10000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

We are recognized as a reliable Manufacturer, Exporter and Supplier of Non Woven Fabric. We can provide Non Woven Fabric in any gram/m2 and any colour required by customer. Non Woven Fabrics are broadly defined as sheet or web structures bonded together by entangling fiber or filaments (and by perforating films) mechanically, thermally or chemically. PP Spun bonded Non woven Fabrics are produced using a precise extrusion-based technology. The polymer is stretched into a continuous filament and loosely spread onto a conveyor belt to form the web. Air is used to form and lay the fabric filaments. On the other hand, some non woven fabrics can be recycled after use, given the proper treatment and facilities.

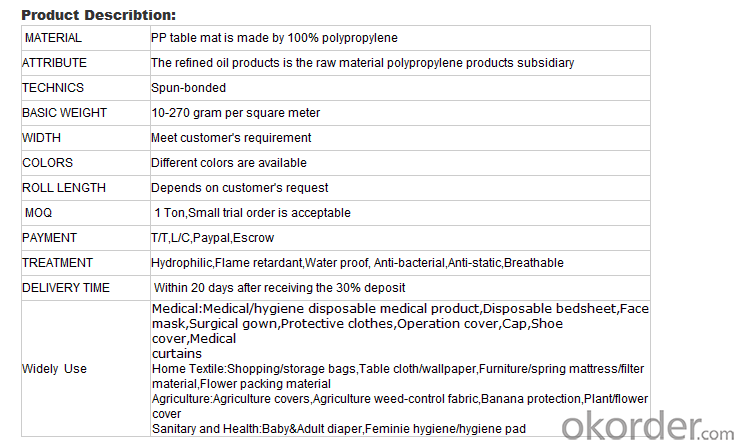

Product Specifications

Weight: 10 - 150 gsm

Width: Max 1600 mm (can be slit)

Fabric Roll Length: As per buyer’s need ( 200 - 1200 Mtr)

Color: various colors available.

Procedure of production: Spun bonded Non Woven, Diamond design

Material: polypropylene

Minimum Order: 1000 Kg

Sample: sample free, freight collect

Product Application

Non woven fabric manufacturers usually manufacture the fabric in a roll form. It is then sent to various other industries where it has end applications, where is it cut and given different form depending upon the use. They can also be used in combination with different materials and offer a wide range of products.

Colored Non woven fabrics are use in many sectors and variety of applications, such as Health, Hygiene, Medical, Packaging, Agriculture, Furniture Upholstery, Geo Textiles, Leather Industry, Shoes and Garments. Customers come from the textile and automotive industries as well as many other sectors.

- Q:The Factors Affecting the Capillary Effect of Textile Garment

- The higher the effect, the better the impact of post-processing quality, such as leveling, dyeing rate, fastness and so on.

- Q:Analysis of import and export of textile

- Data changes show that China's textile industry has entered a cycle from high-speed growth to medium-speed growth, began to adjust the depth of the structure, to speed up the transformation and upgrading of the new history

- Q:The Development of Textile Industry

- From the domestic economic environment, domestic demand will become an important driving force for industry growth. About 80% of Chinese textiles in the domestic consumption. With the sustained and rapid growth of the domestic economy, the stability of residents' income will boost the further development of the domestic market.

- Q:What is the anti-perspiration finishing of textiles?

- Anti-perspiration finishing of textiles and we often say that the perspiration fastness is completely different concept, the anti-perspiration finishing of textiles in the printing and dyeing plant on the side of the fabric side of the hydrophilic side of the waterproof processing

- Q:Is there a large yarn factory or a textile garment factory?

- Spinning process: with cotton, carding, and bars, roving, spun yarn, winding a few processes, at least 7 days or so. MOQ is 5,000 kg.

- Q:Do you need to do environmental protection for dry textile processing?

- Individual industrial and commercial business license is only one, but the composition is divided into two types of family management and personal business

- Q:What is the role of textile degreasing in life?

- Textile degreasing agent, then you can go to Zhongshan Hanke fine chemicals, all kinds of textile printing and dyeing chemicals are. Hope to adopt the answer Thank you

- Q:Classification of textile materials

- According to the raw materials, processing methods and composition of different, can be divided into renewable fiber, synthetic fiber and inorganic fiber three categories. The yarns made from textile fibers are diversified because of the different types of fibers and different forms of yarn processing; the resulting different yarn structures are due to the different physical properties and the use characteristics of the different yarn structures The

- Q:What is the earliest textile raw material?

- The ancient Roman Empire was first through the "Silk Road" on the spread of silk, said China as "silk country"

- Q:Application of Biological Enzyme in Textile Processing

- Hemicellulase, ligninase in the textile processing applications: natural cellulose fibers contain hemicellulose and lignin, especially linen fiber content is high, do not remove hemicellulose and lignin

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

polyester non woven fabric,breathable nonwoven fabric, hydrophobic nonwoven fabric

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 roll

- Supply Capability:

- 10000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords