Top Quality Tear-Resistant Dot Style Recycled Non Woven Fabric

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

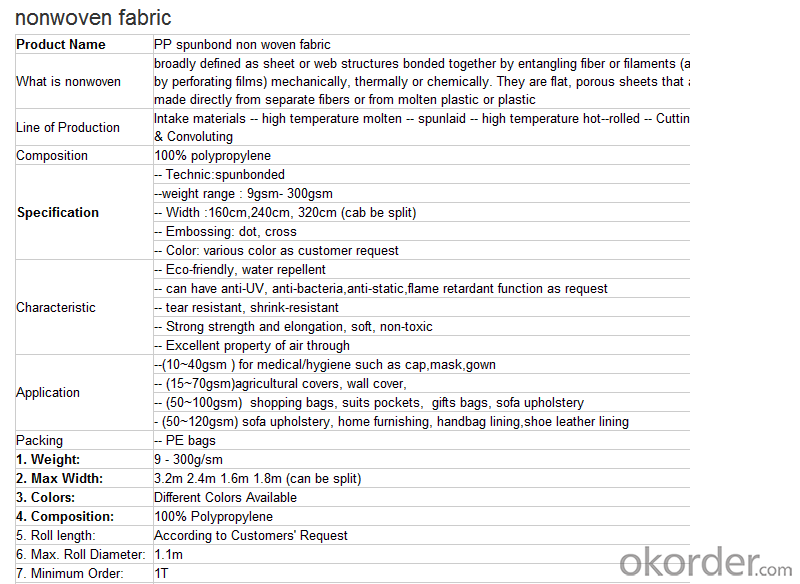

We are recognized as a reliable Manufacturer, Exporter and Supplier of Non Woven Fabric. We can provide Non Woven Fabric in any gram/m2 and any colour required by customer. Non Woven Fabrics are broadly defined as sheet or web structures bonded together by entangling fiber or filaments (and by perforating films) mechanically, thermally or chemically. PP Spun bonded Non woven Fabrics are produced using a precise extrusion-based technology. The polymer is stretched into a continuous filament and loosely spread onto a conveyor belt to form the web. Air is used to form and lay the fabric filaments. On the other hand, some non woven fabrics can be recycled after use, given the proper treatment and facilities.

Product Specifications

Weight: 10 - 150 gsm

Width: Max 1600 mm (can be slit)

Fabric Roll Length: As per buyer’s need ( 200 - 1200 Mtr)

Color: various colors available.

Procedure of production: Spun bonded Non Woven, Diamond design

Material: polypropylene

Minimum Order: 1000 Kg

Sample: sample free, freight collect

Product Application

Non woven fabric manufacturers usually manufacture the fabric in a roll form. It is then sent to various other industries where it has end applications, where is it cut and given different form depending upon the use. They can also be used in combination with different materials and offer a wide range of products.

Colored Non woven fabrics are use in many sectors and variety of applications, such as Health, Hygiene, Medical, Packaging, Agriculture, Furniture Upholstery, Geo Textiles, Leather Industry, Shoes and Garments. Customers come from the textile and automotive industries as well as many other sectors.

- Q:Textile printing and dyeing process which

- Although dyeing can be done through a rolling mill, but also the most difficult process, because the color control of dyeing in addition to the known, there are many uncertainties, such as the stability of the dye at different temperatures, steam control , Rolling pressure control, etc., are very fine live ..

- Q:Application of Biological Enzyme in Textile Processing

- The application of new enzymes in textile processing: the position of chemical synthetic fibers and slurries in the textile is obvious, these polymer can not be biodegradable and degraded, causing environmental pollution, the current researchers are studying the new enzyme

- Q:What is the whole process of textile and apparel trade?

- The control of the process alone to study the British embroidery and other treatment methods, such as fabric mercerizing, washing, tie dyeing, etc. (HTP orders on the British embroidery no detailed information, even in the original proofing even when printing color, printing size is not clear instructions , The customer has only one request: the effect is good on the line

- Q:The development of wool in Australia is not developed.

- The main trading partners are Japan, the United States, mainland China, South Korea, Britain, New Zealand, Singapore, China Taiwan Province, Germany and Malaysia.

- Q:Textile machine, I should use single-phase power or three-phase electricity

- As long as the power of the same, three-phase power and single-phase power production capacity is the same. What is the key to your connector (input) Three-phase electrical industrial electricity, the voltage is more stable

- Q:Lin is what kind of textile

- 3, textile fiber classification: natural fiber and chemical fiber. ① natural fibers, including plant fiber, animal fiber and mineral fiber. A plant fiber such as: cotton, hemp, fruit fiber. B animal fibers such as: wool, hair free, silk

- Q:What is eco textile?

- From the perspective of production ecology, control, including from the fiber cultivation, breeding, production to the whole process of product processing on the environment pollution, the product itself is not "pollution"

- Q:Mechanical characteristics of textile machinery

- A major development feature of modern textile machinery is to continuously improve the speed of the machine, resulting in high yield, to reduce the number of equipment, reduce plant area, save investment and labor, with less money to achieve greater results. Table 1, Table 2, Table 3, the figures show the trend of high-speed textile machinery.

- Q:What is the textile technology profession now?

- Modern woven technology; narrative weaving preparation, winding, warping, sizing, wear knitting, twisting and other processes of the purpose and requirements, process and process parameters of the adjustment method and the impact on product quality, and looms , The opening, weft insertion, winding, sending, decapitation and other five major movement and the role of auxiliary movement, the principle of mastering the main parameters of the loom adjustment method and the impact of product quality.

- Q:Differences between textile mills and garment factories

- In order to have fabric sent to the garment factory made of clothes. Garment factory is made of various kinds of fabric clothing;

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Top Quality Tear-Resistant Dot Style Recycled Non Woven Fabric

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords