Spunbond Polypropylene Non Woven Fabric for Bed Sheets Hospital

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

We are recognized as a reliable Manufacturer, Exporter and Supplier of Non Woven Fabric. We can provide Non Woven Fabric in any gram/m2 and any colour required by customer. Non Woven Fabrics are broadly defined as sheet or web structures bonded together by entangling fiber or filaments (and by perforating films) mechanically, thermally or chemically. PP Spun bonded Non woven Fabrics are produced using a precise extrusion-based technology. The polymer is stretched into a continuous filament and loosely spread onto a conveyor belt to form the web. Air is used to form and lay the fabric filaments. On the other hand, some non woven fabrics can be recycled after use, given the proper treatment and facilities.

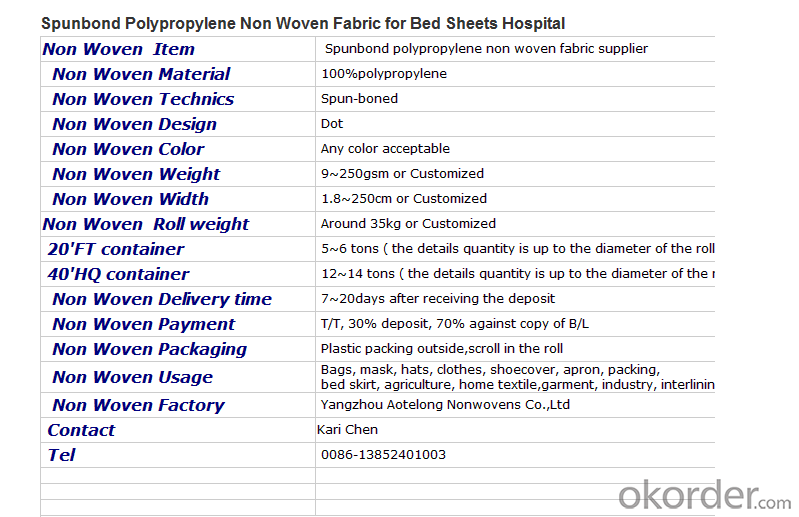

Product Specifications

Weight: 10 - 150 gsm

Width: Max 1600 mm (can be slit)

Fabric Roll Length: As per buyer’s need ( 200 - 1200 Mtr)

Color: various colors available.

Procedure of production: Spun bonded Non Woven, Diamond design

Material: polypropylene

Minimum Order: 1000 Kg

Sample: sample free, freight collect

Product Application

Non woven fabric manufacturers usually manufacture the fabric in a roll form. It is then sent to various other industries where it has end applications, where is it cut and given different form depending upon the use. They can also be used in combination with different materials and offer a wide range of products.

Colored Non woven fabrics are use in many sectors and variety of applications, such as Health, Hygiene, Medical, Packaging, Agriculture, Furniture Upholstery, Geo Textiles, Leather Industry, Shoes and Garments. Customers come from the textile and automotive industries as well as many other sectors.

- Q:What kind of textile is China's export to the United States?

- China's exports to the United States of textile clothing, clothing accounted for about 70%, about 30% of textiles. In 2006, China's textile and garment exports to the United States reached 21.9 billion US dollars, an increase of 18%, of which clothing was 16.3 billion US dollars, accounting for 74% of all exports to the United States; textiles for 5.6 billion US dollars, accounting for 26% The

- Q:The Factors Affecting the Capillary Effect of Textile Garment

- Capillary effect referred to as the effect of wool, textile applications terminology, is the characterization of fabric after pre-processing, the wettability of the measured

- Q:What are the common textile auxiliaries?

- Textile dyeing and finishing auxiliaries in the textile processing technology has a very important role, although the amount is not large, but in the textile processing technology has a role can not be ignored, and sometimes even have an indispensable role, summed up, textile dyeing and finishing auxiliaries In the textile products in the main play a focus on the role

- Q:Textile raw materials of mineral fiber

- A natural or synthetic polymer compounds as raw materials by chemical spinning made of fiber. Can be divided into man-made fibers, synthetic fibers, inorganic fibers

- Q:Is the textile processing and sales tax rate the same?

- Tax rate = tax paid / sales income * 100%. The regional and industry tax rate is different, but in accordance with this standard to

- Q:China is now optimistic about which one of the textile industry

- Advanced geotextile complete sets of production technology and industrial wide high-strength technology-based geotextile, geogrid, waterproof membrane and other high-grade multi-functional geotextile composite materials production and application.

- Q:Classification of textile materials

- Fiber by source and habit is divided into two categories of natural fiber and chemical fiber, or according to Anglo-American chemical fiber is divided into artificial and synthetic fiber two categories, a total of three categories. According to the material properties of the fiber nature of the natural fiber is divided into plant (class) fiber, animal (fiber) and minerals (class) fiber

- Q:Classification of cotton textiles

- Decorative textiles in the variety structure, weave pattern and color, and other aspects than other textiles to have a prominent feature, it can be said to be a craft art. Can be divided into indoor supplies, bedding and outdoor products, including home cloth and restaurant bath room supplies

- Q:What is the earliest textile tool?

- This oblique loom already has a rack, the plane and the level of the seat into a fifty or sixty degrees of tilt. Application of the principle of leverage, with two treads were driven two clues, weaver with a long and a short pedal (rod), were driven

- Q:What is the difference between the mesh pattern on the textile structure?

- Regenerated fiber: his chemical composition and natural cellulose the same, and the physical structure has changed, so called regenerated cellulose fiber. Such as viscose fiber, acetate fiber, copper ammonia fiber, China's main production viscose fiber

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Spunbond Polypropylene Non Woven Fabric for Bed Sheets Hospital

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords