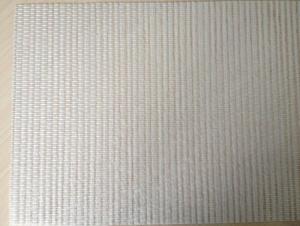

Geosynthetic Fabric

Geosynthetic Fabric Related Searches

Aluminum Vinyl Siding Trim Coil Decorative Solar Lantern White Vinyl Backed Insulation Metal Fabric Decorative Concrete Driveway Decorative Car Accessories Fabric Duct Geogrid Reinforcing Fabric Geogrid Fabric Driveway Sunbrella Fabric CleaningHot Searches

Tilt Panel Props For Sale Fiberglass Scaffolding For Sale Fiberglass Panels For Sale Fiberglass Greenhouses For Sale Geogrid Fabric For Sale Glass Wool Manufacturers In India Mineral Wool Insulation Price List Glass Wool Price List Glass Wool Price India Solar Panel Inverter Suppliers Q Cells Solar Panel Prices Tesla Solar Panel Inverter Geogrid Fabric Price Ceiling Fan Lowest Price Eps Panel Cost Geogrid Fabric Home Depot Geotextile Fabric Cost Per Square Foot Geotextile Filter Fabric Prices Geotextile Filter Fabric Specification Geogrid Fabric PriceGeosynthetic Fabric Supplier & Manufacturer from China

Okorder.com is a professional Geosynthetic Fabric supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Geosynthetic Fabric firm in China.Hot Products

FAQ

- Foam concrete for the roof cushion generally do much bulk ah

- in recent years, the density of 160kg / m3 ultra-light foam concrete is also used in construction projects.

- What is the difference between leveling and cushion?

- Cushion is generally used in the ground floor of the building, leveling layer is generally used in the floor or roof. According to the above analysis, I believe that we use the quota, where the floor, roof construction, it should be used to find the level of the fixed sub-head, because there is no so-called concept of the cushion, leveling layer thickness is not what Specific provisions can also be used at the same time different layers of leveling, but must be carried out in accordance with the design requirements, so as not to exceed the load;

- Do you need a cushion on the ground floor?

- In addition to wood also buy wooden side, used as the main beam, beam and pillars. The ground is also recommended to raise, raise the place also to beam and pillars The number of boards to be based on your design to determine the ground practice, roof practices will affect the number of wood

- Why calculate the amount of time to count a lot of cushion ah

- It can be seen, in the preparation of the project budget, the cushion is also a very important sub-head, the amount of its calculation is often measured by m3, the current commonly used materials are concrete, gravel, stone, Stone slag), slag, slag concrete, lime and so on.

- The cushion is usually in the housing which parts

- Cushion is generally at the base, looking for the use.

- Maintenance time of the cushion on the roof of the building

- According to the "concrete structure construction quality acceptance criteria" provides: Concrete should be poured within 12h after the completion of the concrete to be covered, and moisturizing conservation;

- Basement cushion waterproof

- Third, the membrane waterproof in the construction should first do the basement floor of the waterproof, and then the membrane along the basement floor continuous paste to the outer surface of the wall. Basement floor waterproofing first in the foundation pouring C10 concrete cushion, the thickness of about 100mm. And then paste the membrane, and then in the coil to wear 20 thick 1: 3 cement mortar, and finally pouring reinforced concrete floor. The outer surface of the wall first wip 20mm thick 1: 3 cement mortar, cold base oil, and then paste the membrane, the membrane should be stitched paste, adjacent coil lap width of not less than 100mm. The top of the coil should be higher than the maximum water level of about 500mm, the outer side of the brick wall.

- Can the floor tiles be removed from the cement mats on the prefabricated board floor?

- You can dig, but be careful not to use a strong earthquake with the machinery to remove, otherwise it will damage the original structure.