Plastic PVC Wall Panel Many Different Designs

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 550000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PVC Panel Description

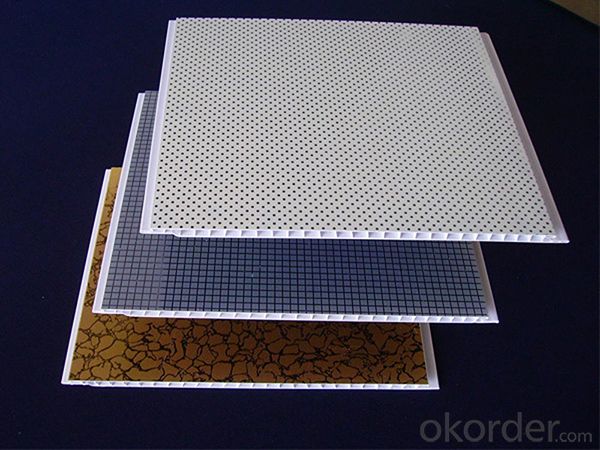

Specification

1)Width:100mm,200mm,250mm,300mm,380mm,595mm

2)Thickness:5mm,6mm,7mm,7.5mm,8mm,9mm,10mm

3)PVC content:30%-80%,as your request.

Feature

1,Easy installation ,surface is smoothness ,flatness, without gap when concatenated.

2,It can be processed by drilling ,sawing, nailing.

3,High intensity, high strength, not easy to deformation, resist erosion, sound insulation,

waterproof, fireproof, aging-resisting, durable

4,Interior decoration for ceiling. Easy clearing, heathy and enviroment.

Characteristic of PVC panel:

Fireproof : Self-fire extinguishing, non-flammable , fire and inflaming retardant.

Waterproof (damp-proof): Resistance to weather/ special chemicals; Waterproof / Washable.

Rustproof (resist erosion) : It is impenetrable by insects or termites, and won' t rot or rust.

Heatproof : Good high temperature impact performance .

High intensity : The excellent rigid and superior impacted surface is without any peeling.

Anti aging : Good aging resistance , durable in all mechanical characteristics .

Quality : Hard quality, high intensity and sheen , fadeless , environmental friendly

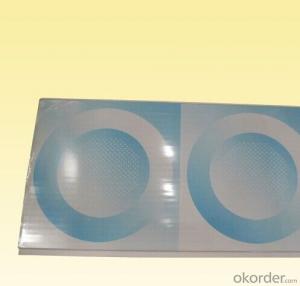

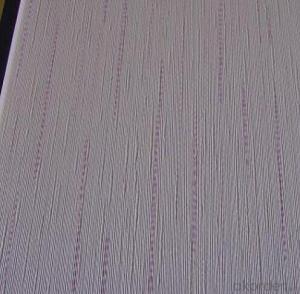

Design : The variety of colors and patterns .Natural wood (marble) grain: showing authentic wood

Easy setting : Light in weight , the simple and fast installation can save a lot of time and manpower

Other : Easy to be cut, drilled, nailed, sawed, and riveted. DIY is all right;

Quick maintenance and no need of painting;

Good resistance fixations.

FAQ

1. Is OEM available?

Re: Yes, OEM service is available.

2. Are you factory?

Re: Yes. we are the largest factory in China.

3. Can we get sample?

Re: Yes, sample is free for our customer.

4. How many days for production

Re: usually 2 weeks after receiving of downpayment

Pictures

- Q:What is the advertising AD board material

- AD board, is the Andy board it ... Andy board, also known as PVC board, the main material is PVC, popular point is plastic. The If it is not sure you can touch the material, if it feels soft and flexible, like lunch box lunch box, that is the KT version; if it is hard, touch like a plastic pipe, that is Andy board The The If you are not sure, watch the surface. Look carefully, the general KT version of the screen are uneven, bumps and small bubbles; and Andy board because of the relatively hard, relatively smooth surface. The If it is not sure, look at the amount of price. General 5mm Andy board than 5mmKT board heavier, and more expensive, is several times the KT version. The If still can not be sure, then on top to let the descendants continue to put up the floor ...

- Q:Whenever we run hot water in the kitchen (faucet or dishwasher), a loud knocking noise comes from the PVC pipes in the basement. It seems to be coming from the main drain pipe which is about 3 or 4 inches in diameter, and it knocks right along the ceiling joists. After a few minutes the knocking stops. Any suggestions?

- it sounds to be a loose system but what you are asking sounds like contraction and expanding from hot water and then it cools off and it goes back to normal, it creeks. its plastic you can insulate it might help

- Q:Like pvc board and so on how to cut, very bad bonding it?

- Production of building materials Materials used: 1: ABS (with different specifications, than 1.0mm, 1.5mm, 2.0mm, etc.) 2: Trichloromethane (ABS extrusion) 3: utility knife (ABS material used) 4: PVC

- Q:Pp board and pvc board 20mm thick now how much money a square?

- Domestic PP20MM board about 18 yuan a kilogram, a square 320 dollars PVC board about 6 yuan a kilogram, a square 170 dollars

- Q:Pvc board ceiling installation method which know? How much is the installation cost?

- When installing the PVC gusset, the secondary bone should be straightened. Buckle plate should be flat, not warping, ceiling flat surface error can not exceed 5mm.

- Q:Often use a black PVC bag to bathe the bath is harmful to the body?

- There, pvc which contains chlorine, received ultraviolet radiation will be released within a carcinogen

- Q:Pvc board to do the props hard, I want to do cos props

- Here with the 8mm board feel quite hard, afraid not hard on a layer of atomic ash

- Q:PVC board, ABS board, KT board What is the difference between ~ ~ What are the purposes?

- PP Polypropylene PVC PVC EPS polystyrene ABS acrylonitrile / butadiene / styrene copolymer PC Polycarbonate PE polyethylene KT board is a light decorative plate, the actual is the two sides affixed with smooth paper foam board, generally used for display panels or as a temporary structure of the partition. KT board can be used for display board production, screen printing, etc., with KT board produced by the beautiful display panels, convenient and light, affordable. (But according to multi-feedback: KT board like a bubble, with a long time will be variant, the proposed use of organic board) KT board color: red, white, yellow, green, gray, blue, black. Two kinds of KD board: one is "enhanced anti-foaming KD board", flatness is good, hardness is strong. Applicable to advertising display, especially for large-scale pictorial inkjet produced a variety of board, he is the best cold plate KD plate. The second is the "economic anti-blister KD board", mainly for the back of the frame, screen printing and silk screen after the POP advertising production. It is the best KD plate to bite the market.

- Q:At present home decoration used in white, beige panels have those? Type with PVC board?

- White maple, white oak, white pine, rose wood, ruminant wood,

- Q:Pvc board do cabinet how exactly? Urgent demand

- Well, beautiful decorative effect is good, durable and solid ah, but also cheap, alternative wood products

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Plastic PVC Wall Panel Many Different Designs

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 550000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords