Perforated Aluminum Sheet Best Quality in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1. Specification of Perforated Aluminum Sheet

Aluminum Coil/Sheet | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

2. Application of Perforated Aluminum Sheet

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Perforated Aluminum Sheet

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

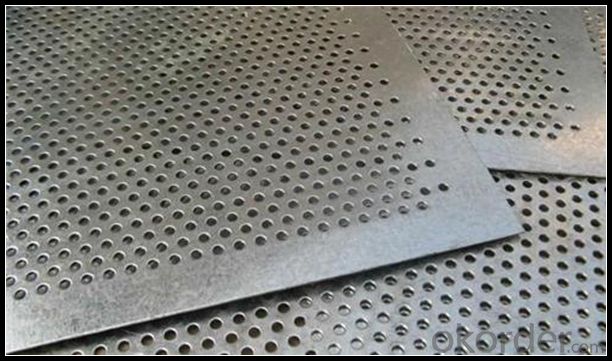

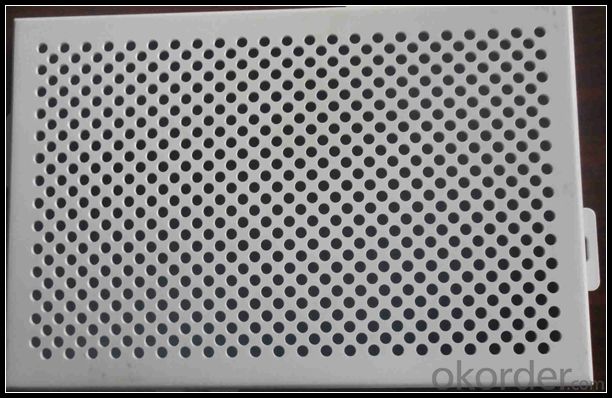

5. Image of Perforated Aluminum Sheet

6. Package and shipping of Perforated Aluminum Sheet

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q:Are aluminum sheets suitable for use in food processing or packaging industries?

- Aluminum sheets are indeed appropriate for utilization in the food processing and packaging sectors. The food industry extensively employs aluminum due to its exceptional properties and advantages. To begin with, aluminum is a safe material for direct contact with food as it is non-toxic. It does not react with food or affect its taste, guaranteeing the preservation of the original flavor and quality. This is particularly crucial in packaging, as it aids in maintaining the freshness and integrity of the food product. Moreover, aluminum possesses excellent thermal conductivity, enabling efficient and uniform heat distribution during food processing. This attribute is advantageous in cooking, baking, and other thermal procedures, ensuring that food is cooked or processed evenly. Additionally, aluminum sheets exhibit outstanding barrier properties, including resistance to moisture, light, and gases. This shields food from external factors that could potentially degrade its quality, such as moisture or oxygen. It also extends the shelf life of packaged food products. Furthermore, aluminum sheets are lightweight, yet sturdy and durable. This makes them easy to handle and transport in food processing and packaging operations. Their strength and durability ensure that the packaging remains intact and safeguards the food during transportation and storage. Lastly, aluminum is an environmentally sustainable material. It is fully recyclable, meaning it can be reused without losing its properties. This aids in reducing the environmental impact and supports the concept of a circular economy. In conclusion, aluminum sheets are highly suitable for use in the food processing and packaging industries. Their non-toxic nature, thermal conductivity, barrier properties, lightweight yet strong characteristics, and sustainability make them an ideal choice for ensuring the safety and quality of food products.

- Q:What is the composition of 101 aluminum sheets?

- The composition of 101 aluminum sheets typically refers to the alloy used in their manufacturing. Aluminum alloy 101 is a commercially pure aluminum with a minimum of 99.0% aluminum content. It does not contain any significant amounts of other elements, making it the most basic and pure form of aluminum available. This high purity level makes it highly resistant to corrosion and provides excellent electrical conductivity. 101 aluminum sheets are often used in applications where a high degree of electrical conductivity or corrosion resistance is required, such as in electrical wiring, heat exchangers, and chemical processing equipment.

- Q:How do you protect aluminum sheets from scratches?

- To protect aluminum sheets from scratches, there are a few steps you can take: 1. Handle with care: When handling aluminum sheets, always be mindful of their vulnerability to scratches. Avoid dragging or sliding them across rough surfaces, as this can cause scratches. Instead, lift and place them gently, ensuring you have a clean, smooth surface to work on. 2. Use protective covering: Before storing or transporting aluminum sheets, consider using a protective covering such as a plastic film or paper. This will provide a barrier and prevent direct contact with other surfaces, reducing the risk of scratches. Ensure that the covering is clean and free from any dirt or debris. 3. Store in a safe environment: When not in use, store aluminum sheets in a clean and dry environment. Avoid storing them alongside abrasive materials or objects that could potentially scratch them. Additionally, consider using dividers or separators to create individual compartments for each sheet, preventing them from rubbing against each other. 4. Clean with caution: When cleaning aluminum sheets, use a soft, non-abrasive cloth or sponge. Avoid using wire brushes or rough materials that can cause scratches. Additionally, use a mild detergent or aluminum cleaner specifically designed for this purpose. Rinse thoroughly and dry the sheets completely to prevent any moisture from causing damage. 5. Apply a protective coating: Another option to protect aluminum sheets from scratches is to apply a protective coating. There are various types of coatings available, such as clear lacquers or specialized aluminum protectants. These coatings create a thin barrier on the surface of the aluminum, adding an extra layer of protection against scratches. By following these steps, you can significantly reduce the risk of scratches on your aluminum sheets and help maintain their appearance and integrity over time.

- Q:How do you prevent warping of aluminum sheets during machining?

- One way to prevent warping of aluminum sheets during machining is by using proper coolant or lubricants during the machining process. This helps in reducing the friction and heat generated, which can cause warping. Additionally, maintaining correct cutting speeds and feeds, as well as ensuring proper tool selection and machining techniques, can also help minimize the chances of warping.

- Q:Can aluminum sheets be an alternative to wood in certain applications?

- Yes, aluminum sheets can be an alternative to wood in certain applications. Aluminum sheets have several advantages over wood, including being lightweight, durable, and resistant to corrosion and fire. They can be used in various industries such as construction, automotive, aerospace, and marine, where wood may not be suitable due to its limitations. However, the selection of material depends on the specific requirements of the application and the desired properties needed.

- Q:What are the different methods of heat treating aluminum sheet?

- Aluminum sheet can undergo various heat treatment methods, each serving a specific purpose and achieving desired outcomes. Some commonly used methods include the following: 1. Solution Heat Treatment: The aluminum sheet is heated to a specific temperature, typically ranging from 900-1000°F (480-540°C), and kept at that temperature for a designated duration. This process aids in dissolving any soluble alloying elements present in the aluminum, resulting in a more uniform structure. 2. Quenching: Following the solution heat treatment, the aluminum sheet is rapidly cooled by immersing it in water, oil, or air. This rapid cooling helps retain the desired microstructure and properties, such as increased strength and hardness. 3. Aging: After quenching, the aluminum sheet undergoes an aging process. It is heated to a lower temperature, typically between 250-450°F (120-230°C), and maintained at that temperature for a specific period. This allows for the precipitation of fine particles within the aluminum, further enhancing its strength and hardness. 4. Precipitation Hardening: This method is specifically employed for certain aluminum alloys, such as the 2000 and 7000 series, which respond well to precipitation hardening. It involves a combination of solution heat treatment, quenching, and aging, resulting in a highly strengthened and durable aluminum sheet. 5. Annealing: Annealing is a heat treatment process that aims to soften the aluminum sheet and relieve any internal stresses. The sheet is heated to a specific temperature, typically around 600-700°F (315-370°C), and then slowly cooled. This enhances the formability and machinability of the aluminum. 6. Stress Relieving: Similar to annealing, stress relieving is specifically used to reduce residual stresses in the aluminum sheet after fabrication. The sheet is heated to a temperature below its annealing temperature and then slowly cooled. The choice of heat treatment method for aluminum sheet depends on the desired properties, alloy composition, and intended application. Each method offers unique advantages and can significantly enhance the mechanical and physical properties of the aluminum sheet.

- Q:What are the different surface finishes available for aluminum sheet?

- There are several surface finishes available for aluminum sheet, including mill finish, brushed finish, anodized finish, and painted finish.

- Q:How to press multilayer aluminum sheets (aluminum sheet's thickness: 0.2mm) together and keep them inseperate after pressing?

- resistance welding is a welding method that pressing the materials to be welded in an area between two poles and switching on current. the current will go through the contact surface and agjacent area, producing resistance heat effect which will heatthe materials into melting or plastic state and make the materials be welded together.

- Q:Are the aluminum sheets suitable for manufacturing automotive fuel tanks?

- Yes, aluminum sheets are suitable for manufacturing automotive fuel tanks. Aluminum is a lightweight and corrosion-resistant material, making it an ideal choice for fuel tank manufacturing.

- Q:What kind of pattern aluminium plate has?

- Aluminum alloy decorative plate: Aluminum shallow pattern boardThe shallow pattern board of aluminum alloy is one of the excellent building decoration materials. It is exquisite pattern, color appearance, has the common advantages of ordinary aluminum plate, the stiffness is increased by 20%, anti fouling, anti scratch, anti abrasion ability has been improved, especially the increase of three-dimensional pattern and beautiful color, make the building more brightly.Aluminium alloy decorative panels: aluminium and aluminium alloy corrugated platesAluminum and Aluminum Alloy corrugated plate is widely used in the world of decorative materials, it is mainly used for wall decoration, can also be used for roofing, surface chemical treatment can have a variety of colors, good decorative effect, but also has a strong reflection of the light, very durable, the service life of up to 20 years. And it has a variety of colors, both decorative effect, but also has a strong ability to reflect sunlight. It can resist fire, moisture and corrosion.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Perforated Aluminum Sheet Best Quality in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords