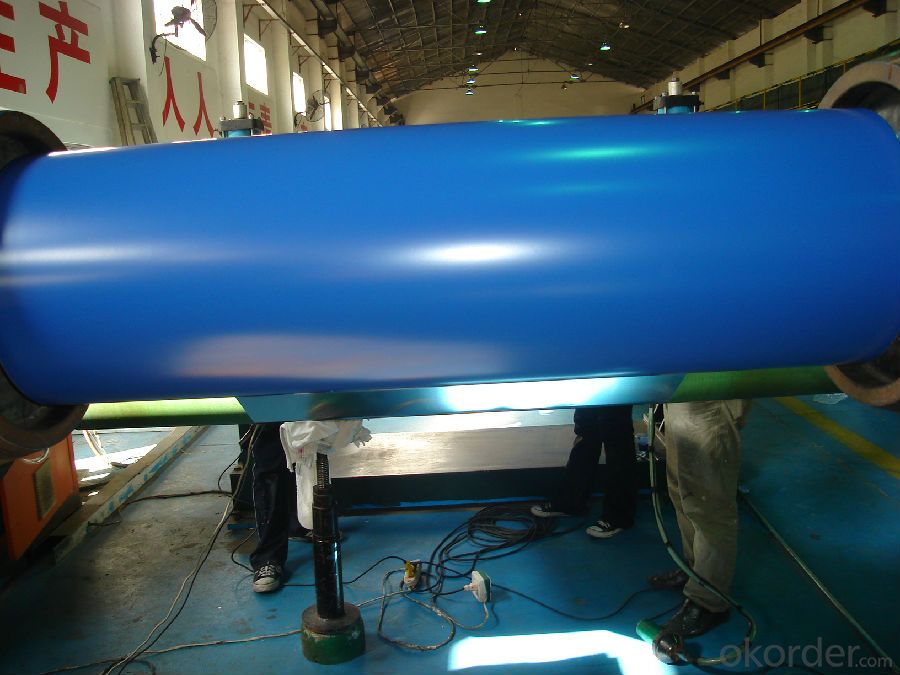

PE Colorful Color Prepainted Aluminum Rolls

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PE Aluminum Coating Coils for ACP

Featuresof PE Aluminum Sheet:

1.Adopting precision rolling coating technology, our PVDF and PE coated coil canensure excellent adhesive without coating omission.

2. For thePE coated aluminum coil we produced, there are various colors for your choice.

3. Usinginfrared heating technology to protect environment from pollution.

4. Ourcoated aluminum coil has four-roller coating line, uniform coating thicknessand good features.

RawMaterial of the PE Aluminum Coating Coils:

1. Aluminum Coil: high strength aluminum withalloy of AA1100 (aluminum alloy is available with AA3003, AA3005, AA5005according to customer)

2. Surface Paint: PE, PVDF and specialpaints.

Specification of PE Aluminum Coating Coil

Width: 20mm~1590mm

Thickness: 0.06mm~1.0mm

External Diameter: ≤ 1500mm

Internal Diameter: 405mm, 505mm, 150mm, 75mm

Coil weight: ≤ 4000kg

PE coated aluminum coil is processed throughthe technics of roller coating and baking with precise polyester paints. Itscolor is glossy and with variety of colors enabling you to choose easily.Chromatic aberration is small, impact resistance is strong and easy to beprocessed, and all its performance has reached or surpassed the nationalcriteria. The products are widely used in indoor and door decoration, ceilings,room surface tiles, corrugated boards, wallpanels, advertisement boards, counters, home appliances, decoration in and outof autos and boats.

Performance of thecoating

Aluminum Thickness | Coating Thickness | MEK | T- Bend | Impact | Adhesion | Pencil Hardness | Boiling Water Proof |

0.3-1.5mm | ≥18μm | ≥100 Times | ≤2T | 50 kg•cm | 0 Grade | ≥HB | no change within 2 hours |

0.2-0.28mm | ≥18μm | ≥100 Times | ≤2T | 30kg•cm | 0 Grade | ≥HB | no change within 2 hours |

0.15-0.18mm | ≥18μm | ≥100 Times | ≤3T | 20 kg•cm | 0 Grade | ≥HB | no change within 2 hours |

0.08-0.12mm | ≥16μm | ≥80 Times | ≤4T | 10 kg•cm | ≤1 Grade | ≥HB | no change within 1 hour |

0.022-0.06mm | ≥12μm | ≥50 Times | - | - | ≤1Grade | ≥HB | no change within1 hour |

Color of Card

PE (polyester)

PE

Color Match

For custom' color requests, we can deal as following:

1. Supply a physical sample of custom color. A color sample on metal ispreferred. If other, it is also acceptable. But the color matching rate may benot good as color on metal.

2. New color sample is usually offered by our paint supplier in 5-7 days,special color should be in 7-10 days.

3. Upon receipt of color sample, please approve in writing as soon as possible.Once you approved, we will arrange purchasing and production.

Note: Color difference maybe occurred in different production batch, so it issuggested all panels are placed in one order for same project. And keep samedirection as arrow on protective film when installing to avoid any colordifference by vision。

- Q:Are aluminum sheets easy to clean and maintain?

- Yes, aluminum sheets are relatively easy to clean and maintain. Aluminum has a natural resistance to corrosion and rust, which makes it a low-maintenance material. To clean aluminum sheets, you can use mild soap and water, along with a soft cloth or sponge. Avoid using abrasive cleaners or scrub brushes, as they can scratch the surface. Additionally, it is important to dry the aluminum sheets thoroughly after cleaning to prevent water spots or stains. Regular maintenance involves wiping away any spills or stains as soon as possible and periodically applying a protective coating to enhance its longevity. Overall, aluminum sheets are a convenient choice for those seeking a material that is easy to clean and maintain.

- Q:Are aluminum sheets suitable for construction applications?

- Yes, aluminum sheets are suitable for construction applications. Aluminum is a lightweight and durable material that offers several advantages in construction projects. It has high strength-to-weight ratio, making it easy to handle and transport while still providing excellent structural integrity. Aluminum sheets are corrosion-resistant, which makes them ideal for outdoor applications. They can withstand exposure to harsh weather conditions, such as rain, snow, and UV rays, without deteriorating or rusting. This resistance to corrosion ensures the longevity of the construction project. In addition, aluminum sheets are highly malleable and can be easily shaped and formed into various sizes and designs. This versatility allows architects and designers to create unique and aesthetically pleasing structures. Aluminum sheets can be used for roofing, siding, cladding, and façade systems, as well as in the construction of windows, doors, and curtain walls. Moreover, aluminum is a sustainable material, as it is 100% recyclable and requires significantly less energy to recycle compared to other metals. This makes aluminum sheets a more environmentally friendly choice for construction projects. In summary, aluminum sheets are suitable for construction applications due to their lightweight, durability, corrosion resistance, malleability, and sustainability. Their versatility and aesthetic appeal make them an excellent choice for a wide range of construction projects.

- Q:What is aluminium oxide sheet?

- Brief introduction:Advantage:(1) good processing: anodized aluminum decorative strong, moderate hardness, easy bending forming, continuous high-speed, convenient and direct processing into products, no need for complicated surface treatment, greatly shorten the production cycle and reduce production cost.(2) good weather resistance: standard thickness of oxide film (3 m) anodized aluminum plate, indoor use for a long time, no discoloration, no corrosion, no oxidation, no rust. Anodized aluminum oxide film (10 m) can be used outdoors, and can be exposed to sunlight for a long time without discoloration.(3) strong sense: the metal surface of aluminum anodic treatment of high hardness, as gem, scratch resistance, surface is not covered with paint, keep aluminum metal color, highlight the modern sense of metal, improve product quality and added value.(4) high fire resistance: pure metal products, the surface without paint and any chemical substances, 600 degrees high temperature does not burn, does not produce toxic gases, fire protection and environmental protection requirements.(5) strong dirt resistance: no fingerprints, no stain marks, easy cleaning, no corrosion spots.(6) applicability: it is widely used in metal aluminum ceiling, curtain wall board, aluminum plastic panel, fireproof board, honeycomb aluminum plate, aluminum veneer, electrical panel, cabinet panel, furniture panel and so on.

- Q:Can aluminum sheets be used for architectural applications?

- Architectural applications can definitely make use of aluminum sheets. Aluminum, being a lightweight and versatile material, offers numerous advantages for architectural projects. It possesses durability, resistance to corrosion, and the ability to withstand extreme weather conditions, making it an ideal choice for different architectural applications like roofing, cladding, facades, windows, doors, and decorative elements. The availability of aluminum sheets in various thicknesses, finishes, and colors allows architects and designers to achieve their desired aesthetic while maintaining structural integrity. With the material's flexibility in being easily shaped, bent, and formed into complex designs, architects are provided with creative freedom and flexibility. Aside from its aesthetic appeal, aluminum is also an environmentally sustainable choice for architectural applications. It is highly recyclable, contributing to a high recycling rate and promoting eco-friendly options. The use of aluminum sheets in architectural projects helps in reducing the carbon footprint and promoting sustainable design practices. Moreover, aluminum sheets offer excellent thermal and acoustic properties that contribute to energy efficiency and sound insulation in buildings. The material aids in reducing energy consumption and enhancing occupant comfort, making it an attractive option for architects and building owners. In conclusion, the versatility, durability, sustainability, and aesthetic appeal of aluminum sheets make them a popular choice for architectural applications. They provide numerous benefits and can be utilized in various ways to create stunning architectural designs while ensuring long-lasting performance.

- Q:Can aluminum sheets be used in marine environments?

- Yes, aluminum sheets can be used in marine environments. Aluminum is a commonly used material in marine applications due to its excellent corrosion resistance properties and lightweight nature. It can withstand the harsh conditions of saltwater, making it suitable for boat building, marine structures, and other marine-related uses.

- Q:What is the width and length of the aluminum sheets?

- The width and length of the aluminum sheets may vary depending on the specific product or manufacturer. It is recommended to refer to the product specifications or contact the manufacturer for accurate measurements.

- Q:Are 101 aluminum sheets suitable for solar panel frames?

- Indeed, solar panel frames can be made using 101 aluminum sheets, which are highly suitable for this purpose. The grade 101 aluminum is widely utilized and recognized for its outstanding strength and ability to resist corrosion. These characteristics render it an optimal material for constructing frames that can endure the elements and offer ample support for solar panels. Furthermore, 101 aluminum sheets are lightweight, facilitating the straightforward installation and transportation of solar panels. In summary, the strength, corrosion resistance, and lightweight properties of 101 aluminum sheets make them a fitting option for solar panel frames.

- Q:What are the different methods of surface cleaning aluminum sheets?

- Depending on the amount of dirt or contamination, there are various ways to clean aluminum sheets. The following methods are commonly employed: 1. Mechanical Cleaning: This method entails physically scrubbing the aluminum sheet using brushes, abrasive pads, or sandpaper. It effectively removes light dirt, grease, or oxidation. However, caution must be exercised to prevent scratching or damaging the surface. 2. Chemical Cleaning: To eliminate dirt, stains, or oxidation, specific cleaning agents or solutions are employed. Alkaline cleaners, acidic cleaners, and solvents are frequently used. It is crucial to adhere to the manufacturer's instructions and take necessary safety precautions when handling chemicals. 3. Pressure Washing: High-pressure water jets are used to eliminate dirt, grime, and other contaminants from the aluminum sheet's surface. This method is quick and efficient, especially for large or heavily soiled surfaces. However, care should be taken to avoid excessive pressure that could dent or damage the aluminum. 4. Electrolytic Cleaning: An electrolyte solution and an electric current are utilized in this method to remove corrosion, oxidation, or tarnish from the aluminum sheet. The sheet is submerged in the electrolyte bath, and the electric current helps dissolve the contaminants. This method is particularly effective for heavily oxidized or tarnished surfaces. 5. Chemical Etching: Chemical etching is a process that selectively removes the surface layer of the aluminum sheet using a combination of chemicals. It is commonly employed to eliminate anodized coatings or to create decorative patterns. However, this method necessitates specialized equipment and expertise. It is important to consider the specific requirements of the aluminum sheet, the level of contamination, and the desired outcome when choosing a cleaning method. Consulting the manufacturer's guidelines or seeking professional advice is always recommended to ensure the most suitable and safe cleaning method is employed.

- Q:Can aluminum plate protect against radiation?

- It can only about radiation, and other materials have not heard of this performance.

- Q:HEY HEY HEY guys its me agian and during today and the six week hoiday i'm gonna be askin a LOT I mean A-LOT ok so firstly I want to ask about drill bit you see as a willing studend who is enginenerring and just now in sience (so please ansewr quikly) what properites does an aluminium oxide drill bit have alot more questions after this one are going to be veary youtube and game related such as what do you guys want me to tweet pewdiepie on fridays whith pewdiepie and so on thanks and bye!!!!!!

- It acts a lubricant.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PE Colorful Color Prepainted Aluminum Rolls

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords