PE Color Coated and Stucco Embossed Aluminum Coils with Thickness 0.2~0.7mm

- Loading Port:

- Yantai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 7 m.t.

- Supply Capability:

- 200 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1. Structure of PE Color Coated and Stucco Embossed Aluminum Coils with Thickness 0.2~0.7mm

Color coated and embossed aluminum coils are widely used for decorations, freezer, refrigerator, central air conditioning and ventilation nozzles, mechanical equipment enclosures and so on.

Embossed aluminum sheets have many advantages. Embossing can not only increase thickness of aluminum, but also enhance strength and rigidity of aluminum coils. Embossed & coated aluminum coils look more beautiful and widely used in decorations.

2. Main Features of PE Color Coated and Stucco Embossed Aluminum Coils with Thickness 0.2~0.7mm

• Light Weight

• Good in strength and rigidity

• High Flatness

• Good Weathering

• Colorful

• Recycling

• Saving Energy

• Rust proof

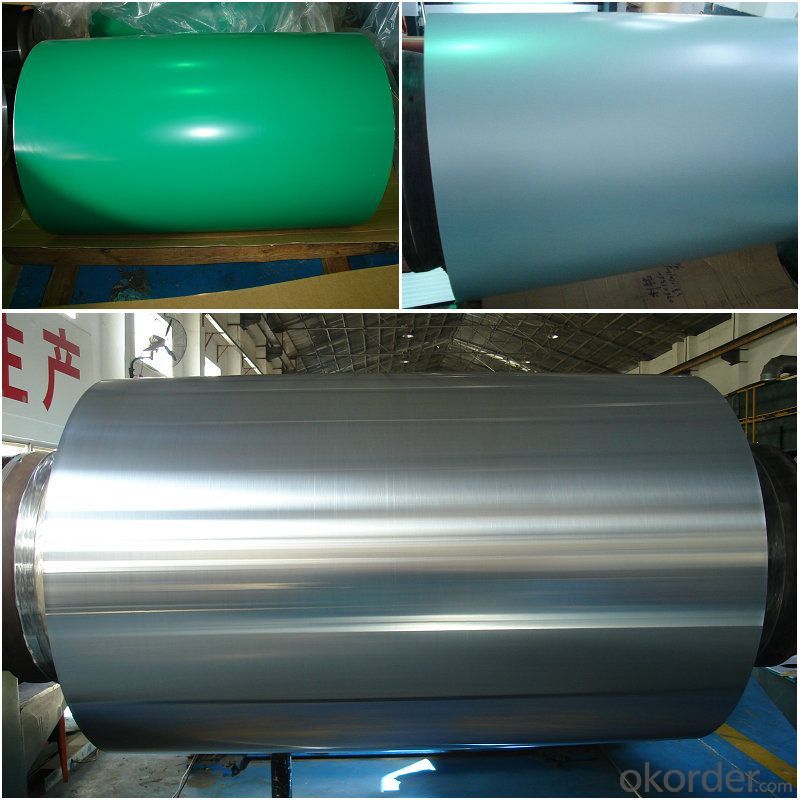

3. PE Color Coated and Stucco Embossed Aluminum Coils with Thickness 0.2~0.7mm Images

4. Specification of PE Color Coated and Stucco Embossed Aluminum Coils with Thickness 0.2~0.7mm

ALLOY | TEMPER | THICKNESS | WIDTH | COATING and COLOR |

3003, 3105, etc | H44, etc | 0.2-0.6mm | Less than1600mm | AS PER YOUR REQUIREMENTS |

5. FAQ

A.What about inspections to guarantee quality?

For each order, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put order in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported?

We have exported to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q:Can aluminum sheet be painted or coated after fabrication?

- Yes, aluminum sheet can be painted or coated after fabrication. The surface of the aluminum sheet can be prepared by cleaning and etching to ensure proper adhesion of the paint or coating.

- Q:What is aluminum sheet material L2?

- L2 is the name of the brand of aluminium plate in our country, which is the 1060 brand now!L1 is 1070L2 is 1060L3 is 1050L4 is 1030L5-1 is 1100And LF-21, or 3003, LF-1, or 3004! Wait

- Q:What is the weight of aluminum sheets per square foot?

- The weight per square foot of aluminum sheets may differ depending on the sheet's thickness or gauge. Typically, a 1/8 inch thick aluminum sheet weighs approximately 1.9 pounds per square foot. Nevertheless, thinner sheets tend to be lighter, whereas thicker sheets can be heavier. It is crucial to take into account the precise thickness of the aluminum sheet when calculating its weight per square foot.

- Q:The diameter of a hole drilled through aluminum at 22°C is 7.50 mm. Find the diameter and the area of the hole at 89°C.

- If i was once you, i might depart a small 1cm gap on the high and cover it with mesh - these round ones don't appear to allow a lot air flow in any respect in my viv and i have three... I have a tendency to simply leave the glass open a bit of at both aspect. You'll have got to use a great mesh although to stop bugs escaping via it. BTW - i think you will have to make it slightly deeper... 1.5 at least in case you are maintaining reps a good way to grow to 12inch plus.

- Q:Are the aluminum sheets suitable for aerospace applications?

- Yes, aluminum sheets are suitable for aerospace applications due to their lightweight nature, high strength-to-weight ratio, and excellent corrosion resistance, making them ideal for aircraft structures and components. Moreover, aluminum's ability to be easily machined, formed, and welded further enhances its suitability for aerospace use.

- Q:Calculate the molar mass of the aluminum oxide. A 5.00g strip of aluminum is reacted in air, producing an oxide weighing 9.36g. Calculate the percent oxygen and aluminum in the compound.Calculate the % error for percent of aluminum calculated.

- 1) Yes, indeed. Al?O? is the correct formula for aluminum oxide. Because the ionic formula is Al?? and O??. (Aluminum has an oxidation number of 3+ ; and oxygen has an oxidation number of 2- . So a neutral ionic compound will have the formula Al?O?. Each element will take the number of the opposite ion.

- Q:When water continually sprays on the aluminum sheet, how to avoid corrosion of aluminum sheet and keep its water resistance?

- Don’t worry about it, after aluminum contacts water or air, a layer of oxide film will generate on its surface to separate aluminum from the water or air and protect it, so it won’t be erosive.

- Q:Aluminum standard 30*25*2500 to 1000 1 how to calculate the number of materials needed?. 2 how to calculate the cutting loss?

- The first is the volume slightly, the aluminum plate as a column volume V= length * width * height =1*2*0.001=0.002 cubic meters and then calculate the quality volume of m= V* density =0.002* density (see you for what kind of concrete, aluminum, aluminum, or Aluminum Alloy? If it's pure aluminum (if it's a high school physics title, or pure aluminum doesn't fit), it's 2700 kilograms per cubic meter.

- Q:What is the yield strength of aluminum sheets?

- The yield strength of aluminum sheets may differ due to several factors, including the aluminum alloy, the tempering process, and the sheet thickness. Typically, aluminum sheets exhibit a yield strength that falls within the range of 10,000 psi (69 MPa) to 45,000 psi (310 MPa). Nonetheless, it is crucial to acknowledge that these values are only estimates and can fluctuate depending on the precise grade and temper of the aluminum in question.

- Q:What is the typical hardness of aluminum sheets?

- The typical hardness of aluminum sheets can vary depending on the specific alloy and temper. However, aluminum sheets generally have a hardness ranging from 40 to 70 on the Brinell hardness scale (HB). This level of hardness allows aluminum sheets to be easily formed, machined, and fabricated, making them suitable for a wide range of applications in industries such as aerospace, automotive, construction, and manufacturing. It is important to note that the hardness of aluminum sheets can be further enhanced through heat treatment processes, such as annealing or hardening, to meet specific requirements and improve their mechanical properties.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PE Color Coated and Stucco Embossed Aluminum Coils with Thickness 0.2~0.7mm

- Loading Port:

- Yantai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 7 m.t.

- Supply Capability:

- 200 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords