PE Butt Welded Flange Socket Flange Pipe Fittings for Pipeline System

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 10000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

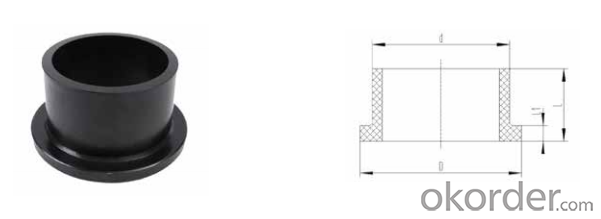

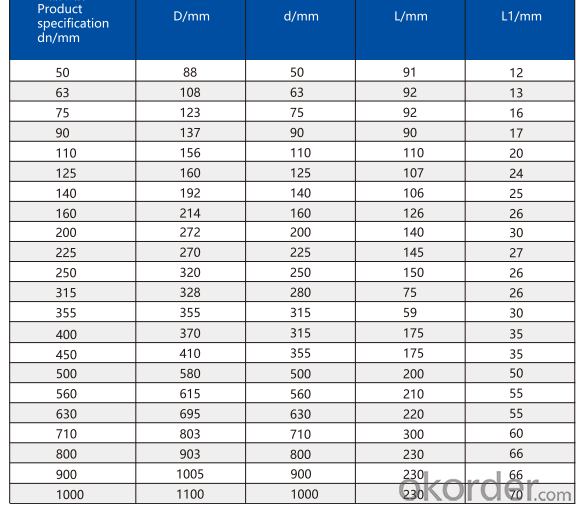

PE Butt Welded Flange Socket Flange

Pressure grade:

PN≤1.6MPa when DN<630MM

PN≤1.0MPa when DN≥630MM

Size: DN50MM-DN1000MM

Specification:

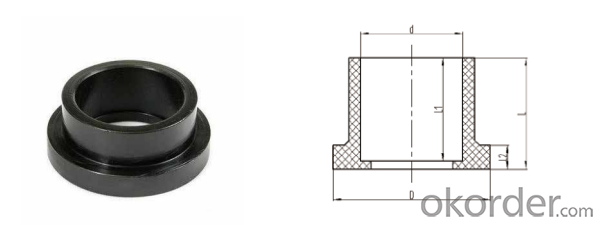

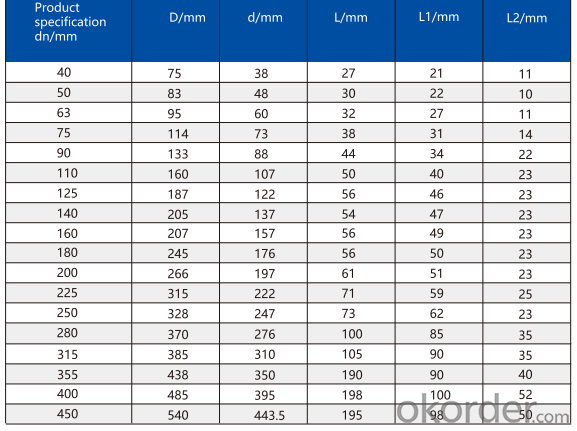

PE Socket Flange

Pressure grade:≤1.6MPa

Size: DN40MM-DN450MM

Specification:

We own three industry bases for manufacturing pipes, fittings and new materials, including the biggest production line of steel wire reinforced PE composite pipe in the world, and top advanced PE pipe production line.

We get long term cooperation with leading material suppliers in the world and professionally provide the pipeline system solutions of matched products and technical cases by the whole industry chain from materials R&D to pipeline engineering installation.

- Q:Are plastic pipe fittings resistant to waterborne bacteria?

- Yes, plastic pipe fittings are generally resistant to waterborne bacteria. They are non-reactive to water and do not provide a favorable environment for bacterial growth, making them an effective choice for preventing contamination in water systems. However, it is important to note that proper installation, maintenance, and regular cleaning are essential to ensure optimal resistance against waterborne bacteria.

- Q:Antistatic flame retardant PE plastic pipe installation, what should pay attention to?

- 1 、 cut the pipe according to the required length, remove the burr of the pipe port and chamfer 30 degrees.2. Insert the pipe into the bottom of the pipe mouth and mark it at the interface of the pipe and the pipe. Then mark the tube out of the 10mm with this mark. Make second more marks. Clean the outer side of the pipe and the inner side of the pipe. Apply a lubricant (not oil or grease).3. The special rubber sealing ring is coated with lubricant and put into the pipe groove, and the pipe is directly inserted into the pipe fitting to the second mark.

- Q:Are plastic pipe fittings resistant to gasoline and oil?

- Yes, plastic pipe fittings are generally resistant to gasoline and oil.

- Q:Are plastic pipe fittings compatible with threaded connections?

- Yes, plastic pipe fittings can be compatible with threaded connections. Many plastic fittings are designed with threaded ends to allow for easy installation and connection to other pipes or fixtures. However, it is important to ensure that the plastic fittings and the threaded connections are compatible in terms of size and material to ensure a secure and leak-free connection.

- Q:What materials are plastic pipe fittings made of?

- Plastic pipe fittings are typically made from various types of thermoplastics such as PVC (polyvinyl chloride), CPVC (chlorinated polyvinyl chloride), PP (polypropylene), PE (polyethylene), or ABS (acrylonitrile butadiene styrene).

- Q:Are plastic pipe fittings resistant to scale build-up?

- Yes, plastic pipe fittings are generally resistant to scale build-up.

- Q:Can plastic pipe fittings be used for gas distribution networks?

- Yes, plastic pipe fittings can be used for gas distribution networks. Many types of plastic, such as polyethylene and polyvinyl chloride (PVC), are commonly used for gas distribution systems due to their durability, corrosion resistance, and ability to handle high pressure. However, it is crucial to ensure that the chosen plastic pipe fittings meet the specific industry standards and regulations for gas distribution to ensure safety and reliability.

- Q:Can plastic pipe fittings be used for industrial waste systems?

- Yes, plastic pipe fittings can be used for industrial waste systems. Plastic pipe fittings are commonly used in industrial applications due to their durability, corrosion resistance, and ability to handle various types of waste materials. Additionally, plastic fittings are typically easier to install and maintain compared to traditional metal fittings, making them a cost-effective and efficient choice for industrial waste systems.

- Q:What are the different types of connections available for plastic pipe fittings?

- Plastic pipe fittings can be connected using various methods, including solvent welding, compression fittings, threaded connections, push-to-connect fittings, and heat fusion.

- Q:How do plastic pipe fittings compare to PVC pipe fittings?

- Plastic pipe fittings and PVC pipe fittings are essentially the same thing. PVC (Polyvinyl Chloride) is a type of plastic commonly used for pipe fittings due to its durability, strength, and resistance to corrosion. So, plastic pipe fittings and PVC pipe fittings are often used interchangeably, and there is no significant difference between them.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PE Butt Welded Flange Socket Flange Pipe Fittings for Pipeline System

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 10000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords