Orange Pattern Embossed and PE Painted Aluminum Coils

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1.Structure of Orange Pattern Embossed and PE Painted Aluminum Coils

We professionally produce stucco embossed and coated aluminum coils, which are widely used in refrigerators, ice-boxes, cold storage, freezer, etc.

Stucco embossed and coated aluminum sheets look more beautiful and better at strength and rigidity than normal aluminum coils.

We normally use 3105, H44 as base coils. Specification of our stucco embossed and color coated aluminium coils: thickness 0.2-0.6mm, width less than 1600mm. As for coating, we normally use PVDF coating, PE coating, etc. We can adjust coating as per customers’ requirements.

2. Main Features of Orange Pattern Embossed and PE Painted Aluminum Coils

• Light Weight

• Good in strength and rigidity

• High Flatness

• Good Weathering

• Colorful

• Recycling

• Saving Energy

• Rust proof

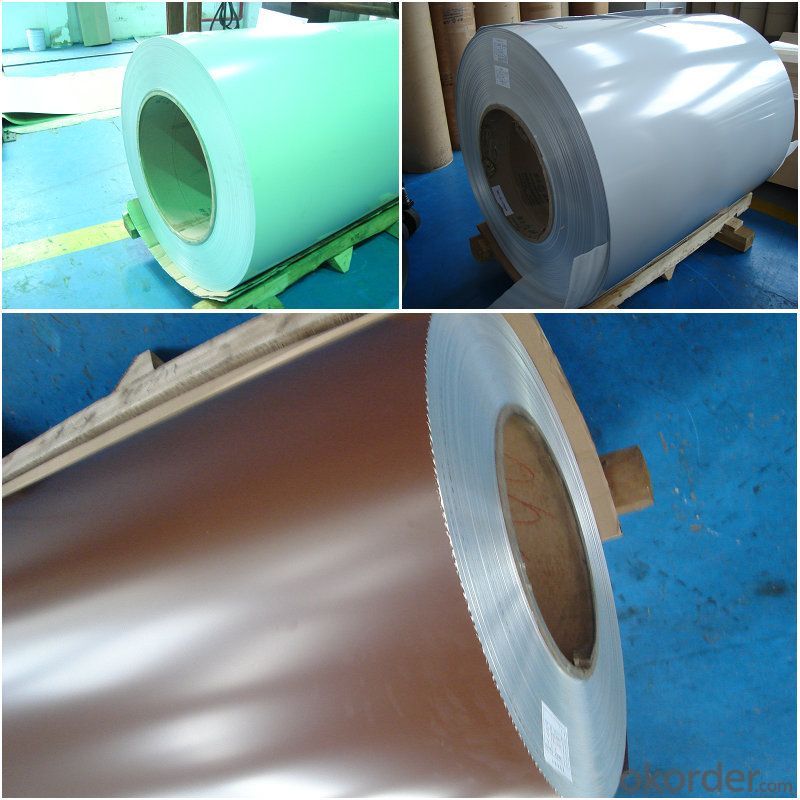

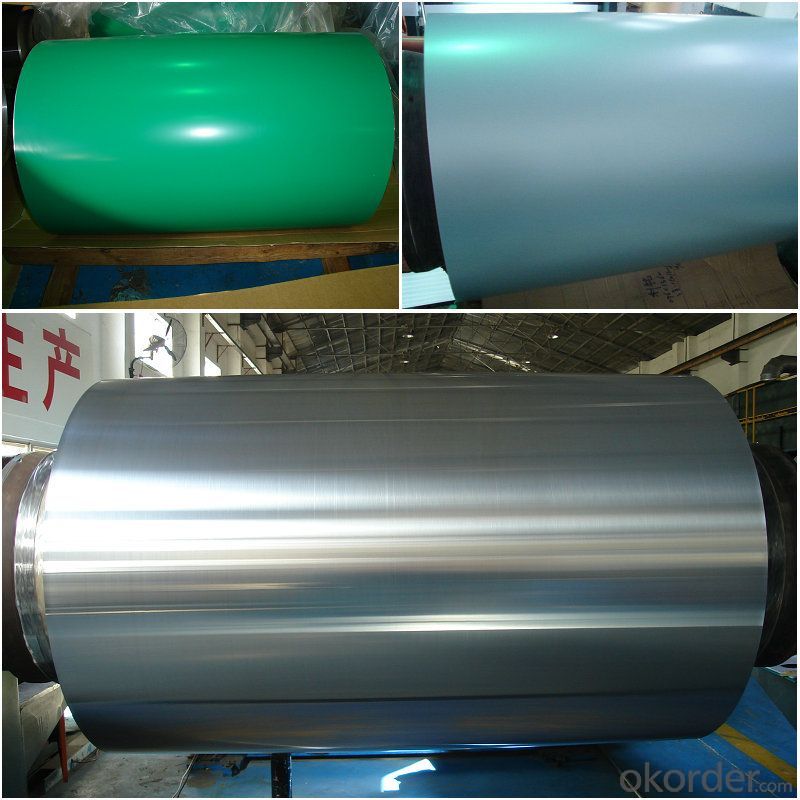

3. Orange Pattern Embossed and PE Painted Aluminum Coils Images

4. Specification of Orange Pattern Embossed and PE Painted Aluminum Coils

ALLOY | TEMPER | THICKNESS | WIDTH | COATING and COLOR |

3003, 3105, etc | H44, etc | 0.2-0.6mm | Less than1600mm | AS PER YOUR REQUIREMENTS |

5. FAQ

A.What about inspections to guarantee quality?

For each order, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put order in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported?

We have exported to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q:what is better for my 96 mustang gt. porting and polishing my stock heads or getting aluminum heads. also could i do a 3v conversion?

- Aluminum. They reduce weight and reduce heat!

- Q:What is aluminum curtain wall.

- In the closing means: aluminum curtain wall aluminum panel curtain wall mounted to the side plate finally called closing!On the aluminum ceiling installation knowledge and aluminum product knowledge welcome Baidu Guangzhou "China Hainan" brand aluminum ceiling understanding

- Q:The corrosion of the aluminum sheet that I request is friction during operation, not the surface of the container after the passivation of the surface of the container containing sulfuric acid. I'd like to use the evaporating plate, the evaporator fin and so on for the cooling in the quick freezing equipment. The ice of ice making machine is attached to the aluminum plate after anodic oxidation or passivation. When it is peeled off, it will cause friction to the surface of the aluminum plate and block the passivation layer, which will make the aluminum plate easier to corrode.

- Directly on the surface coating H2SO4Because the AL and H2SO4 react to produce a dense oxide film that prevents corrosion again, the barrel containing sulfuric acid can be made from AL

- Q:Aren't metals in general (and aluminium in particular) excellent heat conductors?

- Yes aluminium is a good heat conductor, which is why it is used as a heatsink to dissipate heat from electronic components like the CPU in you laptop. The idea of the aluminium stand for your laptop is to raise it up from the desktop surface, allowing air to pass between the gap and extract the heat from the aluminium stand as your laptop heats up with use.

- Q:Can aluminum sheet be used for automotive applications?

- Yes, aluminum sheet can be used for automotive applications. Aluminum is a lightweight and strong material that offers several advantages in the automotive industry. It is widely used in the production of car bodies, hoods, doors, and other structural components. Aluminum sheets are preferred for these applications because they provide excellent strength-to-weight ratio, corrosion resistance, and durability. Additionally, aluminum is easily formable, which allows for complex shapes and designs to be achieved. The use of aluminum in automotive applications also helps to improve fuel efficiency and reduce emissions due to its lighter weight. Overall, aluminum sheet is a suitable choice for automotive applications due to its numerous beneficial properties.

- Q:What is the maximum temperature aluminum sheets can withstand?

- The ability of aluminum sheets to tolerate high temperatures is influenced by various factors, such as the composition and thickness of the alloy, as well as the specific application and environment. Pure aluminum, in general, has a melting point of approximately 660 degrees Celsius (1220 degrees Fahrenheit), but its strength and rigidity decrease at lower temperatures. Commercial aluminum alloys, on the other hand, have higher melting points and can endure greater temperatures. For instance, the melting point of 6061 aluminum alloy is roughly 580 degrees Celsius (1076 degrees Fahrenheit), while the melting point of 7075 aluminum alloy is slightly higher at around 640 degrees Celsius (1184 degrees Fahrenheit). Nevertheless, it is important to highlight that the maximum temperature that aluminum sheets can handle without significant distortion or structural harm may be lower than their melting point. This is due to the fact that aluminum's mechanical properties and strength deteriorate at elevated temperatures. When using aluminum sheets in applications involving high temperatures, it is crucial to consider the specific alloy and its thermal characteristics, as well as any potential alterations in strength, hardness, or other pertinent properties that may occur at elevated temperatures. Consulting material specifications, engineering guidelines, or seeking advice from metallurgical experts can provide more accurate and specific information regarding the maximum temperature capabilities of aluminum sheets for a particular application.

- Q:Alumina is the protective coating that covers aluminum when exposed to oxygen. It's actually corroded aluminum that prevents the aluminum from continuously corroding.What I didn't know until recently was that alumina is an electrical insulator. If that's the case why then isn't aluminum an insulator if one is trying to pass current along its surface?

- Aluminum is an efficient conductor of electricity. A usual fabric that is not conductive is glass but glass will habits heat. Wood isn't warmth conductive or an electricity conductor however has a low combustion factor. You probably have a specific utility you are watching for then you definitely'd better ask extra certain questions.

- Q:1995 s10 I took this whole thing apart and marked and labled everything. Now i have an aluminum head sitting on a bucket that was spraying water right from the head gasket but the head gasket is in perfect shape, and there are no cracks i can see on the head. One more thing, the truck would not start up with water in it, but it would when it was drained, like it was blocking the spark or something. yes it did overheat has this ever happened to anyone else, and any ideas? Thank you.

- Could be 1 of 5 things Blown intake gasket Blown head gasket Cracked head Cracked block Warped head. Most of the times you will not see a crack with your eyes. The head needs to be magnafluced or pressure tested to see if theres a crack. Check your phone book for machine shops. An engine machine shop will check a head for cracks for around $20-40 per head To check if its Warper you can do that with a true flat, straight edge like a long steel rule, and a feeler gauge. Lay rule on bottom of head where gasket goes (all traces of old gasket cleaned off 1st), Try to slide a .001 feeler gauge under rule. If warped a machine shop can mill head flat for around $35-50 per head

- Q:What are the different alloys available for aluminum sheets?

- There are several different alloys available for aluminum sheets, each with its own unique properties and applications. Some of the most common alloys include: 1. 1100: This is a commercially pure aluminum alloy with excellent corrosion resistance, making it suitable for applications where high levels of corrosion resistance are required, such as in marine environments. 2. 3003: Another commercially pure alloy, 3003 offers good formability, high corrosion resistance, and moderate strength. It is commonly used for general sheet metal work, cooking utensils, and chemical equipment. 3. 5052: This alloy is known for its high fatigue strength and excellent corrosion resistance, particularly in saltwater environments. It is often used in marine applications, as well as for aircraft components and fuel tanks. 4. 6061: A heat-treatable alloy, 6061 exhibits good weldability and formability, along with high strength and excellent corrosion resistance. It is commonly used in structural components, such as frames and railings, as well as automotive parts. 5. 7075: This alloy is known for its high strength-to-weight ratio, making it ideal for aerospace applications and high-stress structural components. However, it is less corrosion resistant than other alloys and may require protective coatings in certain environments. These are just a few examples of the alloys available for aluminum sheets. The choice of alloy will depend on the specific requirements of the application, such as strength, corrosion resistance, formability, and cost. It is important to consult with a knowledgeable supplier or engineer to determine the most suitable alloy for your specific needs.

- Q:Are aluminum sheets suitable for bulletproof applications?

- Aluminum sheets have not typically been deemed appropriate for bulletproof applications because they are relatively weak and less dense compared to other commonly used bulletproof materials, such as steel or ballistic ceramics. Despite having good corrosion resistance and a high strength-to-weight ratio, aluminum lacks the necessary hardness and toughness to effectively halt or slow down bullets. In contrast, materials like steel or ballistic ceramics possess superior properties that allow them to withstand the impact of ballistic projectiles. For instance, steel has both high hardness and strength, enabling it to absorb and disperse the energy from a bullet upon impact. On the other hand, ceramic materials have high compressive strength and hardness, causing them to shatter and absorb the energy of a bullet, thereby preventing penetration. In summary, while aluminum sheets may have various uses due to their resistance to corrosion and lightweight nature, they are generally unsuitable for bulletproof purposes. To achieve effective protection against ballistic threats, it is advisable to consider materials specifically designed and engineered for such purposes, such as steel or ballistic ceramics.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Orange Pattern Embossed and PE Painted Aluminum Coils

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords