Non-Asbestos Calcium Silicate Board With Low Price and High Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Applications:

Gypsum board building systems are easy to install for several reasons. Gypsum board panels are relatively large compared to other materials. They come in 48- and 54-inch wide sheets and in lengths of 8, 10, or 12 feet, so they quickly cover large wall and ceiling areas. Gypsum board assemblies require only a few tools for their construction. Gypsum board can be cut with either a utility knife or a variety of saws, and it can be attached with a variety of fasteners, including screws, nails, and staples. It can also be adhesively attached to many substrates. Gypsum board is a lightweight material. Two workers can easily handle most panels and cover large areas in very short time periods. Gypsum board is easily finished using either a few hand tools or relatively modest machines. Gypsum board installers can quickly learn most application techniques in a few hours.

Product Advantages:

Gypsum board is used to construct strong, high quality walls and ceilings that offer excellent dimensional stability and durability. Surfaces created using gypsum board are easily decorated and refinished.

3) Economy

Gypsum board is readily available and easy to apply. It is an inexpensive wall surfacing material that provides a fire resistant interior finish. Gypsum board building systems can generally be installed at significantly lower labor costs than most alternate systems.

4) Fire resistance

Gypsum board is an excellent fire-resistive building material. In North America, it is the most commonly used interior finish where fire resistance classifications are required. Its noncombustible core contains nearly 21% chemically combined water, as described earlier, which, under high heat, is slowly released as steam. Because steam will not exceed 212 dgreees F under normal atmospheric pressure, it very effectively retards the transfer of heat and the spread of fire. Even after complete calcination, when all the water has been released from its core, gypsum board continues to serve as a heat-insulating barrier. Moreover, tests conducted in accordance with ASTM E 84 show that gypsum board has a low flame-spread index and a low smoke-density index. When installed in combination with other materials in laboratory-tested wall and ceiling assemblies, gypsum board serves to effectively protect building elements from fire for prescribed time periods.

5)Sound isolation

Preventing the transfer of unwanted sound to adjoining areas is a key consideration when designing a building, specifically when taking into account the intended activities of the occupants in the various parts of the building. For example, a building containing office spaces adjacent to manufacturing facilities requires more noise-reducing features than are typically necessary in a building that has only office space in it. Gypsum board wall and ceilings systems effectively help control sound transmission.

Main Product Features:

1.Framework

We recommend to use of Galvanized Steel to build the frame. Using metal studs ensures accuracy, and they will not move or twist due to shrinkage or water ingress. In either case set studs at maximum 600mm centres.

2. Align the board

Gypsum board are laid horizontally. Start at one end and align the first board along the studs. Securethe board with screw at 250mm centres, ensuring that the screw are at least 15mm from the board edge. Do not overdrive the screws.

3. Clean the adjacent board edges

In order to ensure that maximum adhesion is achieved when jointing, the adjacent edges of the fixed board and the next board in sequence must be cleaned. Sinmply clean the edges with a wet brush to remove traces of dust - the edges do not need to be soaked.

4. Interior Joint Adhesive

Using a suitable gun, apply a continuous bead of interior. Joint Adhesive to the adjacent edge of the fixed the boards. The bead should be of sufficient size to fill the joint fully when the next board is offered up.

5.Place the next board

Align the next board and push it firmly into the bed of adhesive. The gap between boards shoul be less than 1mm. Secure the board with Screws.

6. Scrape of the excess adhesive

Scrape off the excess interior joint adhesive the next day using a flexible steel scraper.

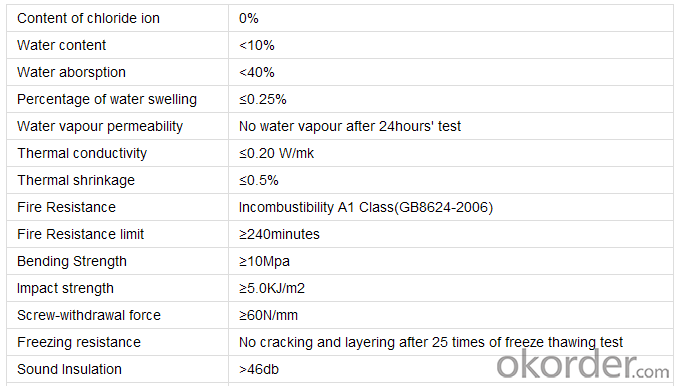

Product Specifications:

Images:

- Q:My home decoration ceiling, decoration company reported is easy to licensing calcium carbonate board to do smallpox, how ah, environmental protection? And the concrete board to identify it

- Calcium silicate board is now a lot of domestic asbestos, will cause lung cancer and mesothelioma, carcinogenic probability is very large, and now engage in decoration are generally funny (there are some companies do not have the ability to produce asbestos calcium silicate board With asbestos board posing), give you with asbestos calcium silicate board

- Q:Home improvement ceiling with a special board, scraping the cover is a good place is rural?

- Yes. Etter board is not calcium silicate board. The name of the Aite plate is a fiber-reinforced silicate plate. The board is imported from the plant fiber, not the ordinary calcium silicate board. Often the national standard is low. Etter board thickness has a lot of 6-12mm range. But for the ceiling is also due to project vary. Some room ceiling related to fire protection requirements, then they usually choose low-density series 8mm or 10mm; some just a simple office ceiling, then use the density of 6mm can be completely.

- Q:Should go to what unit inspection, please experience the peer talk about, thank you!

- Calcium silicate board fire can reach less than 3 hours, to fiber reinforced silicate fire board can be achieved, specifically you can go to the national fixed fire detection system testing center in Tianjin. There is a Sichuan Dujiangyan National Fire Detection Center to detect. Beijing Jinyuan Hengxin Building Materials Co., Ltd. is specialized in producing this fire board.

- Q:Calcium silicate board water absorption on the performance of the plate have any effect

- The absorption of water vapor moisture is not enough to change the performance of the plate, and low density stability better, so the site recommended the use of low-density sheet, because the lighter the lighter the better.

- Q:Calcium silicate board how to deal with smooth surface, that is, I would like to foil in the calcium silicate board, is to be very common to paste the bottom,

- The first lower number of sand belt sand flat, and then a high head of the belt polishing, pits or wood fiber fluff easily blistering, you can try or ask the belt or sanding equipment manufacturers

- Q:Cement fiber board calcium silicate board

- Fiber cement pressure plate and calcium silicate board in common 1, both of the raw material composition is similar, all contain silicon powder, calcium and fiber. 2, both through the process of pulping and copying. 3, both the appearance of the shape and length and width specifications are basically the same. 4, both in the use of many overlapping areas, such as inside and outside the wall and so on.

- Q:Integrated ceiling and calcium silicate board which is good

- Waterproof fire performance than the wood is much better ... ... and easy to clean up not afraid of soot But it is bad to return to the South do not absorb the water ... ... but also anti-tide ... ... that is likely to drip down

- Q:Autoclaved aerated concrete slabs and fiber reinforced calcium silicate boards which are good

- Not the same use, bad comparison, calcium silicate board to do the surface decoration materials used

- Q:Calcium silicate board production line

- Calcium silicate board production line by the ingredients machine, pulp machine, slurry tank, mixer, plate machine, blank machine, stripping machine, steam curing machine, dryer and milling machine, with the conveyor, conveyor composition Complete fiber reinforced calcium silicate board production line. The production line with high efficiency, low energy, high capacity, economic and reasonable advantages.

- Q:Calcium silicate board seams with what kind of waterproof tape can be affixed firmly. The

- First analyze the cause of cracking. Calcium silicate board ceiling cracking for three reasons: First, keel problems. If the use of light steel keel, the thickness of more than 0.8 mm, if the thickness of the wood keel to 3.5 cm or more.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Non-Asbestos Calcium Silicate Board With Low Price and High Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords