Fire Rated Calcium Silicate Boards

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Applications:

1.100% non-asbestos

2.Bending strength 13MPa

3.Nonflammability A grade

4.Waterproof / fireproof

Calcium Silicate Factory

Product Advantages:

Calcium silicate board is made from wood lengthy fiber, concrete

and silicon sand, under the high pressure water vapor process, therefore, it performs

well in humidity durability, force resistance and fire proofing. fiber

cement board is suitable for indoor partition, ceiling and decoration.

fiber cement board presents the art of Germany know-how as a high quality

building material. It contains inorganic raw materials such as cement, silica powder

and reinforced cellulose fiber as the main materials. All boards are

autoclaved to become stable product. fiber cement board does not contain

any of asbestos fiber; however, it has strong bending strength like those with

asbestos.

fiber cement board can be applied not only for the interior use but also

for the outdoor wall system. It has low water absorption rate and high impact resistant

ability. These good advantages make it suitable for any purposes of applications.

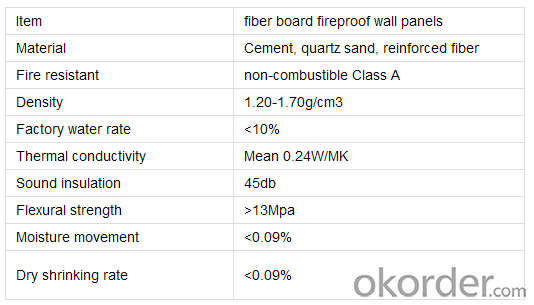

Main Product Features:

1) 100% non-asbestos

2) Density: 1,000 - 1,400kg/cbm

3) Coefficient of thermal expansion: 0.24W/MK (JC/T54)

4) Bending strength: over 13MPa (GB/T7019-1997)

5) Linear expansion rate: 0.1%

6) Water absorption rate: less than 0.19% (GB/T7019-1997)

7) Water penetration rate: 0%

8) Water content: 10%

9) Incombustibility according to CNS 6532 and BS 476

10) Two point five three hours of fire rating for (6mm wall system with W-CSP concrete)

11) Radioactivity: standard (GB6566-2000)

12) Characteristic: nonflammability A grade (GB-8624-1997)

1) Heat insulation, stability, damp-proof, sound insulation, fire resistance and

light weight

2) The wall is solid and firm inside, and resistant to impact pressure

3) Painting, tiling and nailing is possible in the new system .

4) Noise reduction can be up to 46dB

5) Good efficiency

6) Working environment can keep it dry and clean for better management

7) Certificates with 2.53 hours of fire rating.

Product Specifications:

Images:

- Q:Buy the house is fine decoration, wood flooring poor quality to tile bathroom ceiling is calcium silicate board, it is necessary to replace it? Need to change the material of the ceiling?

- If it is calcium carbonate plate can not be replaced, calcium silicate board itself tide!

- Q:Calcium and calcium silicate board and calcium carbonate plate distinction and contact

- Polymeric ceilings gypsum board, better. Because it is relatively soft, hardness is not very hard. It is relatively easy to shape. The operation is simple. But no calcium silicate board waterproof performance.

- Q:What is the use of calcium silicate board with calcium silicate board ceiling is good

- Calcium silicate board is made of inorganic mineral fiber or cellulose fiber and other loose short fiber as a reinforcing material, with siliceous-calcium material as the main cementing material, pulping and molding, accelerating the curing reaction in high temperature and high pressure saturated steam to form Calcium silicate gel made of the plate. It is a kind of new building and industrial sheet with excellent performance. Its products are fireproof, moisture - proof, soundproof, insect - resistant and durable, and it is an ideal decorative plate for ceiling and partition.

- Q:Paper gypsum board, calcium silicate board, silicon calcium board difference

- The main raw material is natural gypsum powder (CaSO4), white cement (calcium silicate), glue, glass fiber. Strength is much higher than the gypsum board; completely changed the gypsum board due to moisture and deformation Fatal weakness, several times to extend the service life of the material.

- Q:Does the calcium silicate factory pollute? What is the harm to people? Please know the big god reply! Thanks

- Quartz powder, these carcinogens harmed; autoclaved alkaline drainage process, COD content is also high, and some plants are chaos row, and some plants can do zero emissions; then there is the flue gas produced by coal, the general factory Do not meet the emission requirements of it

- Q:Should go to what unit inspection, please experience the peer talk about, thank you!

- There is a wall technical specifications, you can buy the bookstore to see, "JGJ / T157-2008 building lightweight strip wall technical regulations"

- Q:What are the extruded boards and calcium silicate board adhesives?

- Calcium silicate board on the requirements of the adhesive is relatively lower, generally used in polymer mortar mortar on it. Or else I add my Baidu HI chat, perhaps more exchanges

- Q:Glass magnesium board VS calcium silicate board who can be better

- Ingredients: glass magnesium board for the magnesium oxide, magnesium chloride chemical reaction products, is one. Calcium silicate board is a cement, yellow sand aggregate, is a physical reaction. Color: glass magnesium board is generally milky white, magnesium oxide and magnesium chloride is the raw material color, density between 0.9-1.3, belonging to light fire board, and calcium silicate board in 1.5 or more, is a heavier a building materials.

- Q:What is the difference between perforated calcium silicate wallboard and gypsum board?

- Perforated calcium silicate wallboard as a new environmentally friendly building materials, in addition to the function of the traditional gypsum board, but also has excellent fire performance and moisture resistance, the advantages of long life, in the practical use of a wide range of applications. Our unit is used in Jiangsu Sanxian Architectural Acoustics System Co., Ltd. production of perforated calcium silicate wallboard.

- Q:Calcium silicate board commonly known as what

- Insulation with calcium silicate board is called microporous calcium silicate, is a white, hard new insulation material, with a light weight, high strength, thermal conductivity is small, high temperature, corrosion resistance, can cut, Widely used in electric power, metallurgy, petrochemical, construction, ship and other areas of equipment piping, wall roof insulation and fire insulation. Thickness is usually above 30mm. Density in the 200-1000kg / m3.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Fire Rated Calcium Silicate Boards

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords