Calcium Silicate Boards Non-asbestos JN Standard Type

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1,Structure of (Calcium Silicate Boards) Description

1. High density 130kg/m3--950kg/m3

2. High working temp. 1150C.

3.100% no asbestos .

4.Low thermal conductivity <=0.040w/m.k

2,Main Features of the (Calcium Silicate Boards)

1:Good durability, and can withstand high-temperature limit of the continuous thermal load

2:We obtained CE, KR and ISO9001

3:The highest heat resistance temperature is up to 1150 degree centigrade

4:The maximum flexural strength is up to 0.7MPa,all Technical Parameters are the best in China, it is better than other calcium silicate board in the market.

5 Our factory is corporate with the big power plant, uses the steam of the power plant to product the board, it is different from other factories to produce with the boiler. The product use the steam, the quality is better than use the boiler, so the technical parameters of our product are the best in factory. And it is very easy to mass product and reduce the waste, the cost is lower than our factory use boiler. So that the product from our factory is best quality and cheapest price.

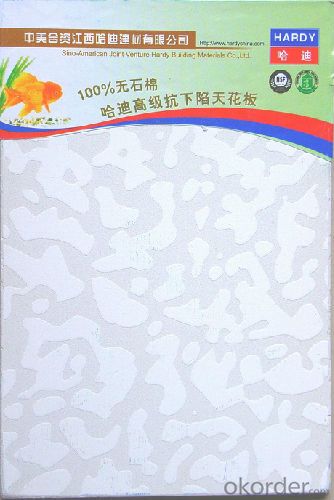

3,(Calcium Silicate Boards) Images

4,(Calcium Silicate Boards) Specification

Size & Loading Quantity of Calcium Silicate Board:

| Thickness (mm) | Length x width (mm) | PCS/ 20GP | Surface |

| 5mm | 1200mm x 2400mm 1220mm x 2440mm | 1050 PCS /

| Single, double surface Sanding or tapered |

| 6mm | 1200mm x 2400mm 1220mm x 2440mm | 880 PCS /

| Single, double surface Sanding or tapered |

| 8mm | 1200mm x 2400mm 1220mm x 2440mm | 656 PCS /

| Single, double surface Sanding or tapered |

| 9mm | 1200mm x 2400mm 1220mm x 2440mm | 588 PCS /

| Single, double surface Sanding or tapered |

| 10mm | 1200mm x 2400mm 1220mm x 2440mm | 520 PCS /

| Single, double surface Sanding or tapered |

| 12mm | 1200mm x 2400mm 1220mm x 2440mm | 442 PCS /

| Single, double surface Sanding or tapered |

Customized sizes and thickness are also produced.

5,FAQ of (Calcium Silicate Boards)

Package

1.Hold by Wooden Pallet

2.Covered by PVC and Bonded with plastic belt

3.Fasten around the corners

4.Mounted in container to protect your purchasing

Our Services:

We have own factory to produce the boards, and we are not the trading company, so we would have the directly customer service and the warranty of our boards is very good! If you need samples we can proviod first then start production as your requirement!

- Q:Calcium silicate board to do the external wall paint how to construction

- If the direct application of calcium silicate board (plate) on the batch of putty powder prone to fall off (gray) phenomenon, we must first primer, it is recommended to use the home of the German brand brackish putty to scratch again (TB) To be dry and then approved by the external wall putty powder (2-3 times) leveling.

- Q:What is the calcium silicate board used in the bathroom ceiling

- Waterproof gypsum board ceiling, brush waterproof paint, simple and easy (easy to clean, difficult maintenance, moisture effect is poor)

- Q:Calcium silicate board equipment

- Calcium silicate board and cement fiber pressure plate are suitable for decoration, external wall insulation, ceiling and so on. The same raw materials: cement, fiber, calcium silicate, calcium silicate board less cement, cement fiber pressure plate cement and more. Production process: calcium silicate board: flow slurry method, copy method cement fiber pressure plate: copy method, flow slurry process: calcium silicate board: raw materials - plate - stripping - steam curing cement fiber pressure plate: raw materials - The difference between fiberboard pressure plate is the cement, fiber and other raw materials after the pulping copy molding by thousands of tons of press pressed to take The copy of the law to produce. Calcium silicate board is made of siliceous and calcareous fiber material after slurry slurry molding, in high temperature environment, autoclaved production.

- Q:Calcium silicate board water absorption on the performance of the plate have any effect

- The absorption of water vapor moisture is not enough to change the performance of the plate, and low density stability better, so the site recommended the use of low-density sheet, because the lighter the lighter the better.

- Q:Silicon calcium board ceiling workers how much money a square meter

- Local wages vary, the above is for reference only. More with your local workers to inquire about the price is clear.

- Q:Two layers of calcium silicate board in the middle of what kind of sound insulation board

- Calcium silicate composite rockwool sound insulation board, but now with less, mainly out of environmental protection, the use of area considerations.

- Q:What are the advantages of calcium silicate board?

- The high-rise fire can be seen, because the welding so that the organic insulation layer of fire caused a major fire, if the use of calcium silicate board is absolutely impossible to such a tragedy. Comparison of all building plates, consider the above factors, the most economical is the calcium silicate board.

- Q:What is the difference between perforated calcium silicate wallboard and gypsum board?

- Silicon calcium board was first used in high temperature furnace insulation. Such as "in order to improve the quality of shaft kiln clinker material, easy to coal blending and reduce clinker burning coal consumption, we must strengthen the kiln kiln body insulation.Often the practice is to use the internal insulation method, refractory layer, the total thickness of the insulation layer should be ≥ 650mm, near the kiln wall should be added ≥ 60mm calcium silicate board or aluminum silicate fiber mat ".

- Q:What is the use of high-temperature calcium silicate board? I want to find a material can be resistant to high temperature 1500 ℃, and must be pressure,

- Calcium silicate board is not able to fire more than 1000 degrees, and fire detection, only in a certain temperature and time the flame can not penetrate, that is, no crack on it

- Q:Door head decoration, outside the aluminum-plastic plate which can be used calcium silicate board?

- General 2-3M of the door are no problem. As well as look at your door on the decorative effect, anyway, is not too heavy!

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Calcium Silicate Boards Non-asbestos JN Standard Type

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords